Interior part of vehicle and manufacturing method thereof

A manufacturing method and vehicle technology, applied to vehicle parts, vehicle seats, special positions of vehicles, etc., can solve the problems of extremely difficult stitch pattern joint stitching, high sewing difficulty, stitch pattern misalignment, etc., and improve the appearance design sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A case will be described in which the first embodiment of the vehicle interior component and the manufacturing method thereof according to the present invention is applied to a vehicle seat used in an automobile or the like as a vehicle interior component.

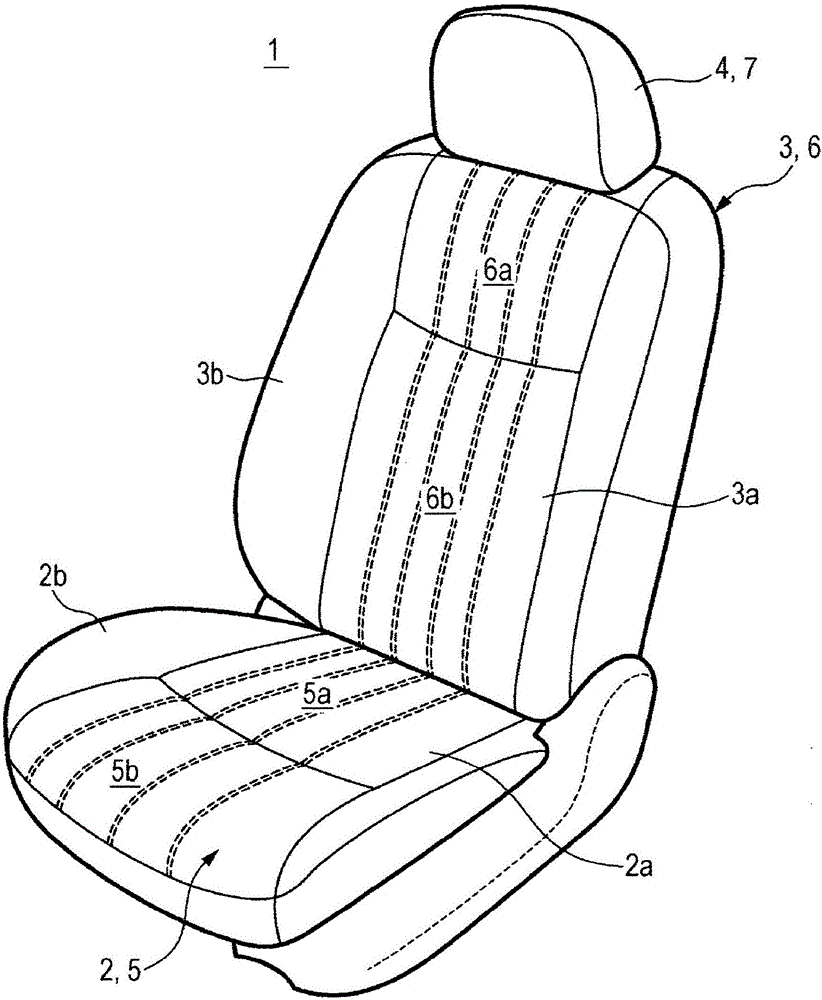

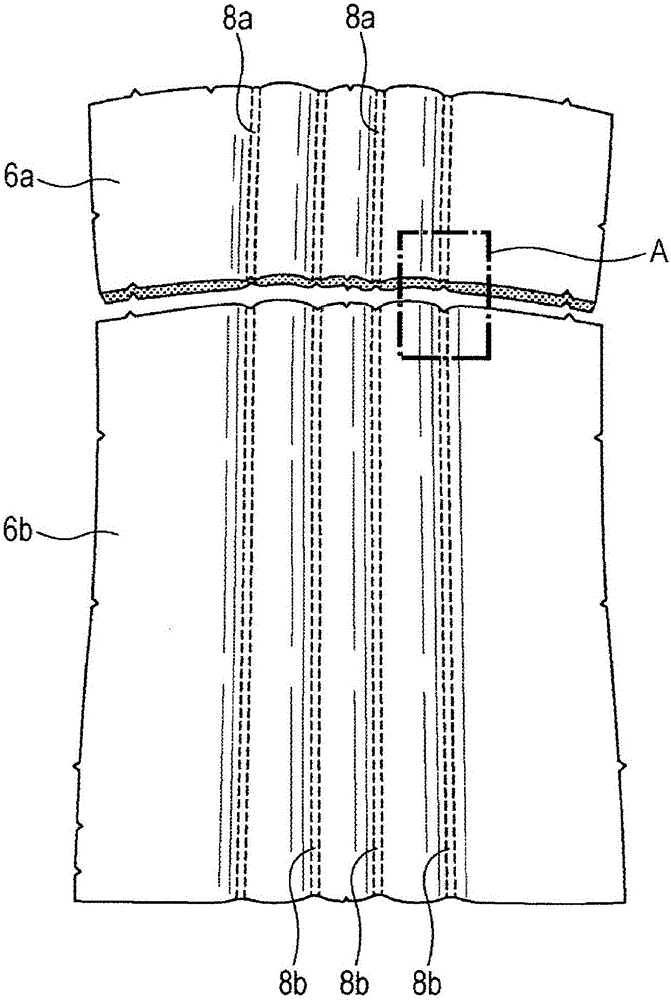

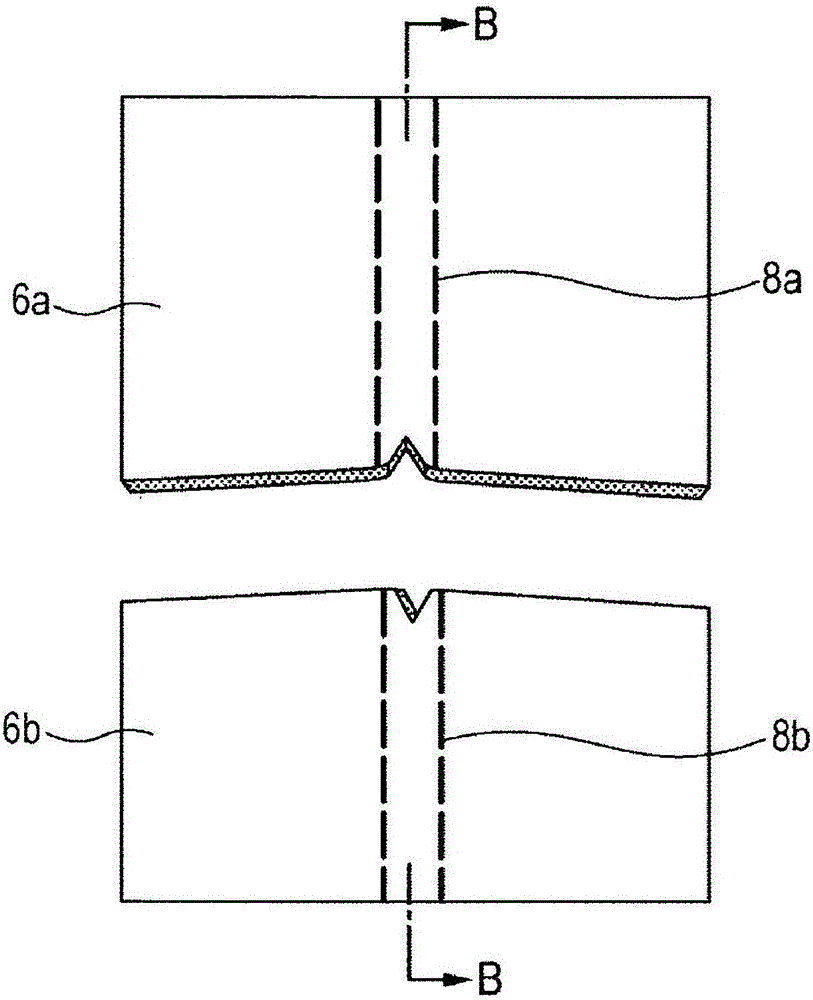

[0033] figure 1 It is a figure which shows Example 1 of the vehicle interior component of this invention, and is an overall perspective view of the vehicle seat which is a vehicle interior component.

[0034] Such as figure 1 As shown, a vehicle seat 1 has a seat cushion 2 as a seat portion of the seat, a seat back 3 as a back portion of the seat, a headrest 4 for protecting the head and neck of an occupant, and the like.

[0035] The seat cushion 2 is provided with a seat surface portion 2a at a central portion and side support portions 2b as supports for side portions of the seat surface portion 2a. The seat back 3 is also provided with a seat back portion 3 a at a central portion and side support portions 3 b a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com