Sorting device and method for mixed storage and sorting of multiple specially-shaped cigarettes

A technology of mixed storage and equipment, applied in the direction of conveyor, conveyor objects, transportation and packaging, etc., to achieve the effect of easy manual smoke filling, simple equipment structure, and saving sorting space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

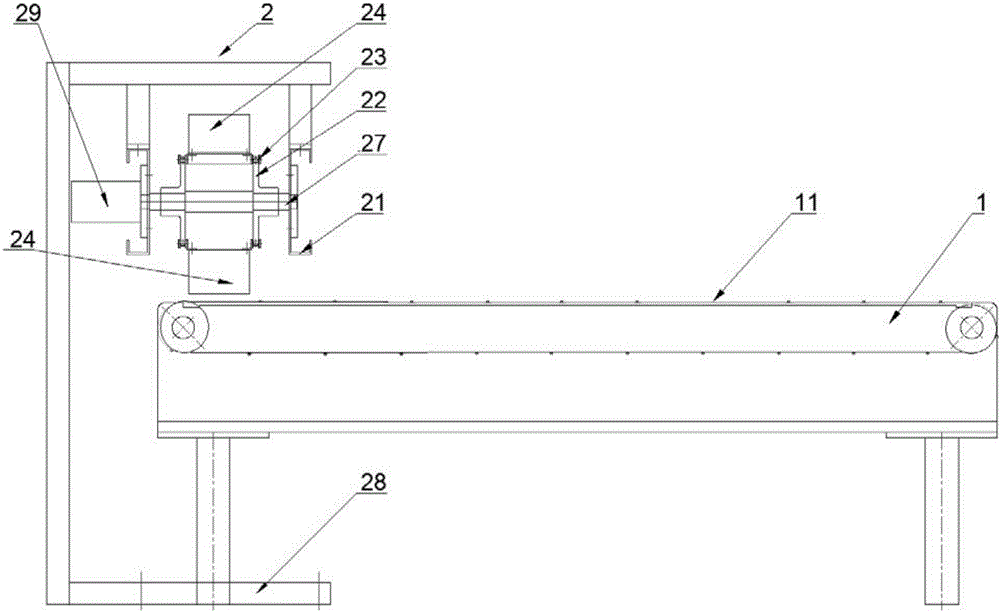

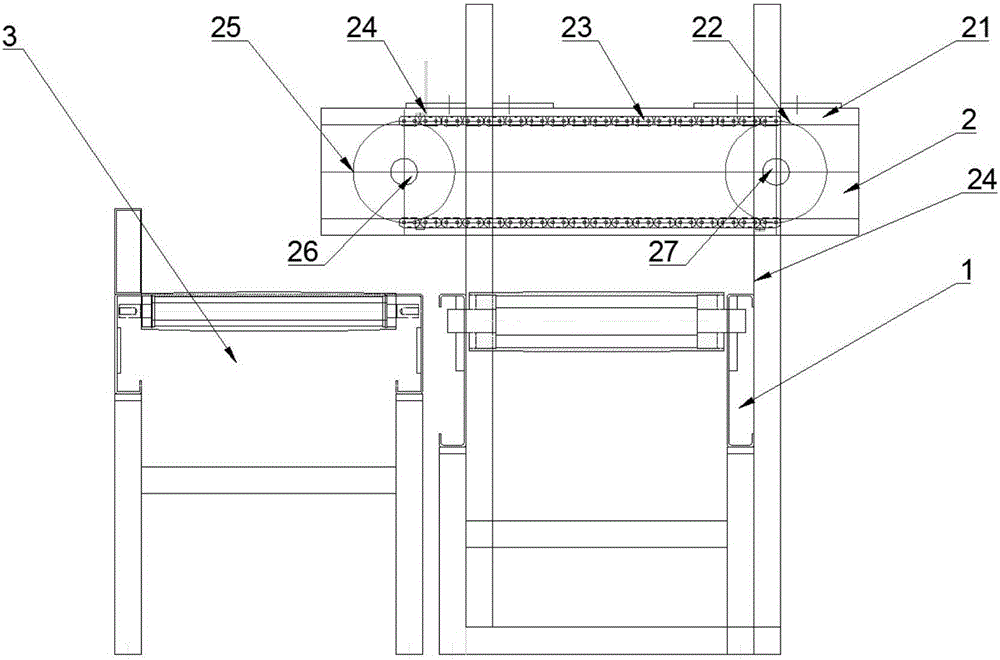

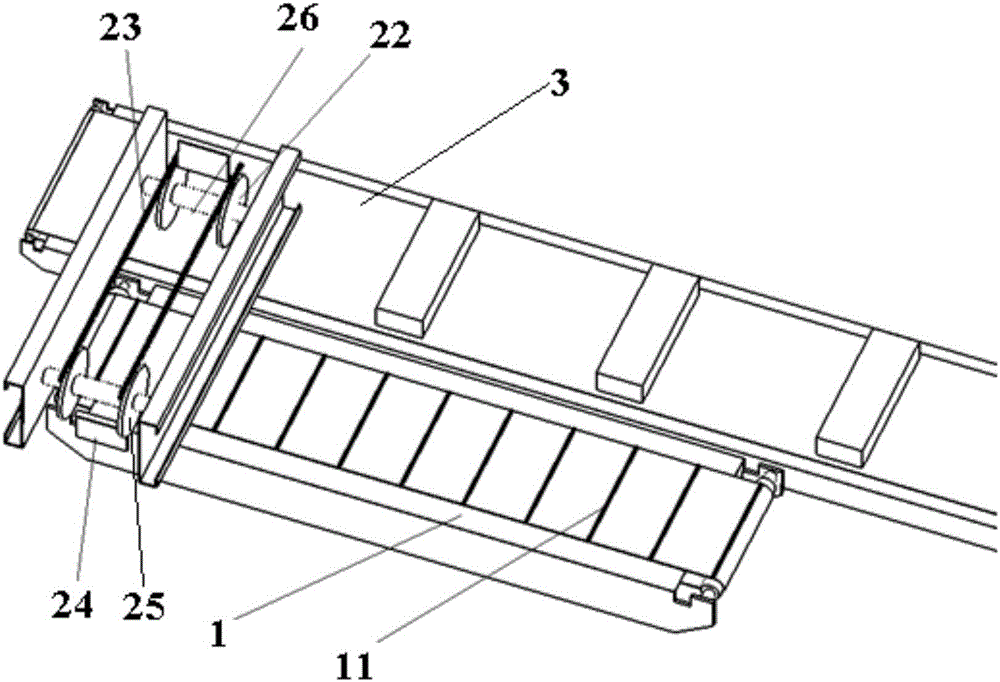

[0026] refer to figure 1 , the sorting equipment used for mixed storage and sorting of various special-shaped cigarettes described in this embodiment, the equipment includes: a cigarette filling belt conveyor 1 and a smoking equipment 2; the smoking equipment 2 is arranged on the cigarette filling Belt conveyor 1 transmits above the front end;

[0027] The smoking device 2 includes: a first frame 21, a second frame, a drive shaft 27, a driven shaft 26, two sprocket units, two smoking plates 24, a motor 29 and legs 28; The first frame 21 and the second frame are arranged opposite and parallel to each other, and are vertically fixed to the drive shaft 27 and the driven shaft between the first frame 21 and the second frame. 26 are on the same horizontal plane, and the two sprocket units are arranged side by side, and are all perpendicular to the drive shaft 27;

[0028] Each sprocket unit includes a drive sprocket 22, a driven sprocket 25 and a chain 23, and the connection rela...

Embodiment 2

[0034] This embodiment is based on the sorting method of the sorting equipment used for mixed storage and sorting of various special-shaped cigarettes as described in Embodiment 1. The method includes:

[0035] According to the order requirements, the special-shaped cigarettes required in the order are sequentially placed in the storage space formed between the guide bars 11 provided on the belt conveying surface of the cigarette filling belt conveyor 1;

[0036] The special-shaped smoke is conveyed to the smoking position located at the forefront of the smoke replenishing belt conveyor 1, and then the smoke-making equipment 2 drives the special-shaped smoke into the main transmission belt conveyor 3, and the transmission direction of the main transmission belt conveyor 3 is the same as the above-mentioned The transmission direction of the smoke filling belt conveyor 1 is parallel.

[0037] Among them, the special-shaped smoke is driven into the main transmission belt conveyor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com