Anaerobic internal circulation reactor

An anaerobic internal circulation and reactor technology, applied in the field of anaerobic reactors, can solve the problems of high sludge content, complex working state of the internal return system, insufficient power of the internal circulation system, etc., and achieve the effect of abundant power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

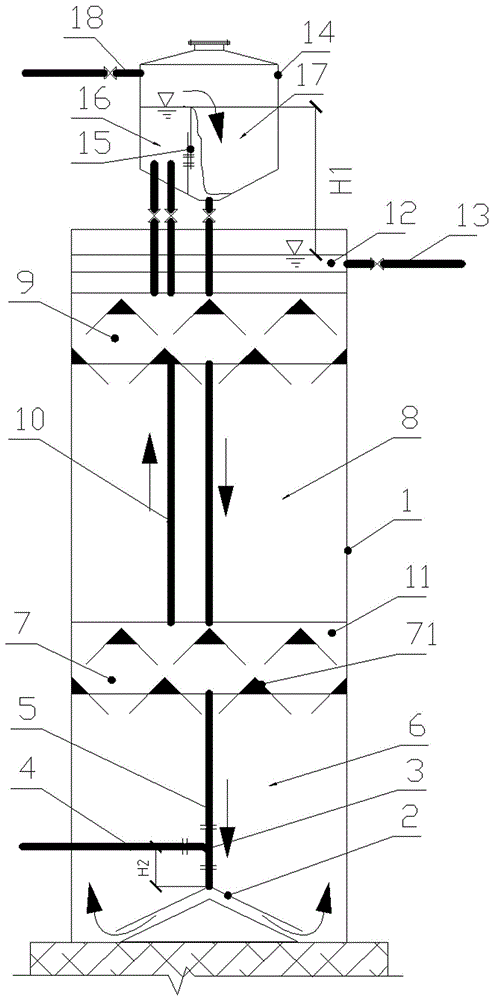

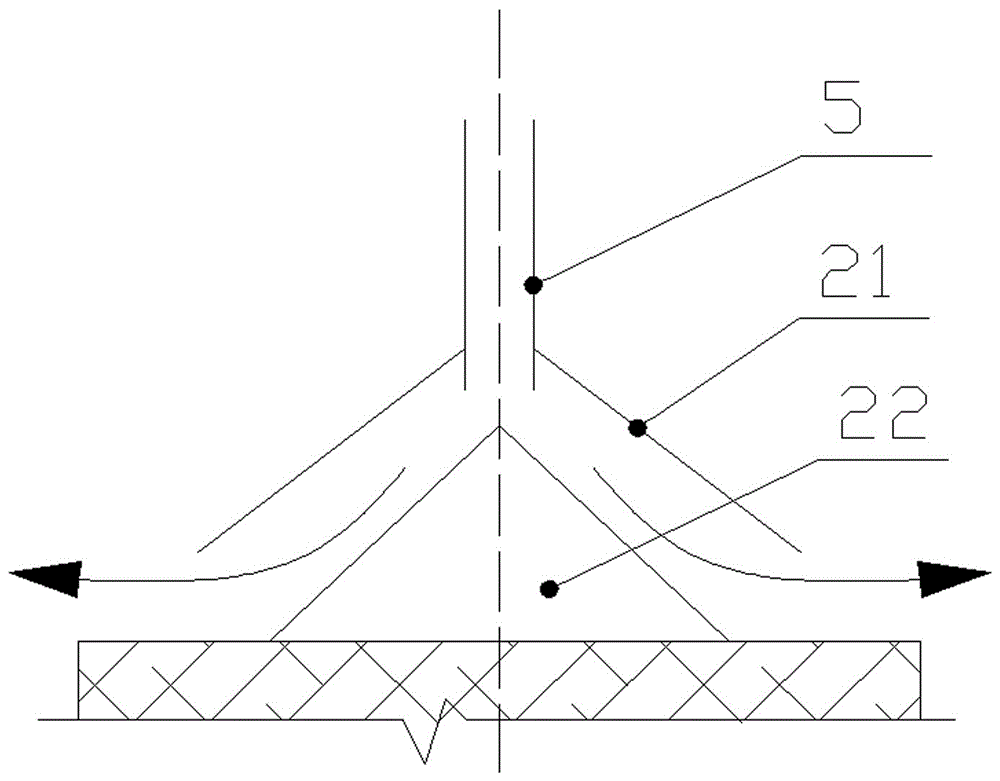

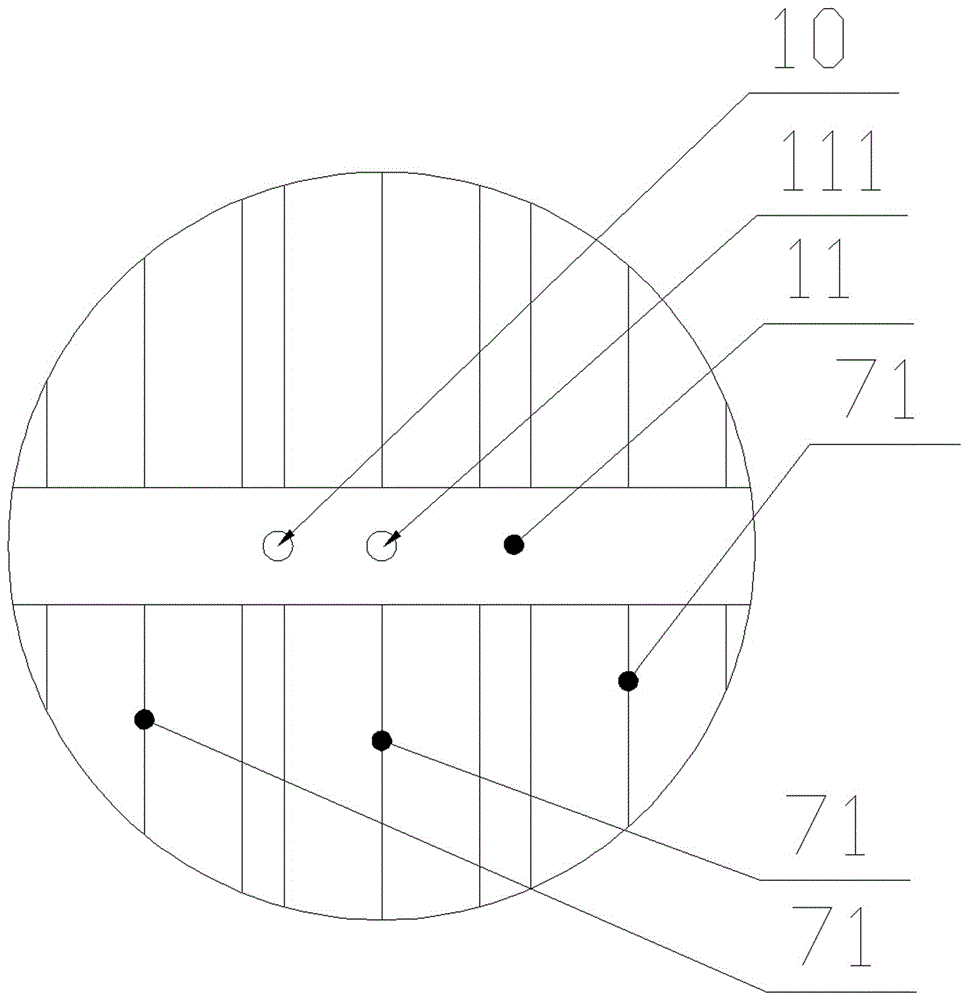

[0031] see Figure 1 to Figure 3, an anaerobic internal circulation reactor, including a reactor cylinder 1 and a gas-water separation box 14 located at the top of the cylinder. A first reaction zone 6 and a second reaction zone 8 are arranged in the reactor cylinder 1 from bottom to top, and the bottom of the reactor cylinder 1 is provided with a water inlet pipe 4 and a flow guiding device 2, and the water inlet pipe 4 It communicates with the upstream end of the flow guide device 2 , and the downstream end of the flow guide device 2 communicates with the first reaction zone 6 in the reactor cylinder 1 . The gas-water separation box 14 is supported on the top of the reactor cylinder 1 by a bracket. The upper part of the gas-water separation box 14 is provided with a biogas outlet for connecting with the biogas pipe 18, and a height-adjustable overflow weir 15 is arranged in the gas-water separation box 14 to separate the gas-water separation box 14 into mixed Liquid rising...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com