Method for making biofuel from biological sludge

A biological sludge and biomass technology, applied in the direction of fuel, sludge treatment, solid fuel, etc., can solve the problem of unmade biomass fuel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

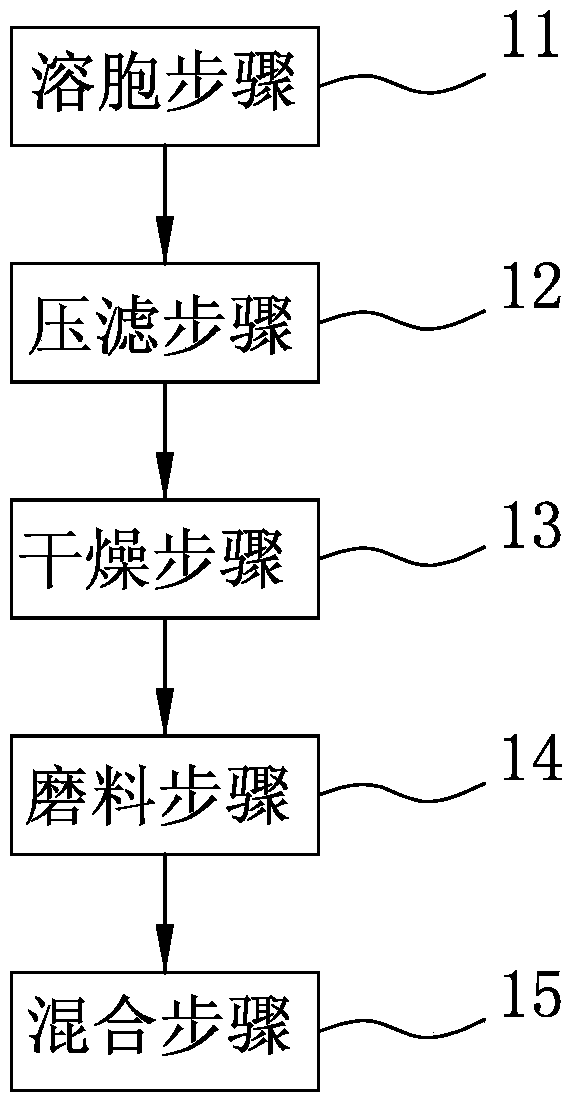

[0022] refer to figure 1 , is an embodiment of the method for making biofuel from biological sludge of the present invention, which embodiment includes a lysis step 11, a filter press step 12, a drying step 13, an abrasive step 14, and a mixing step 15.

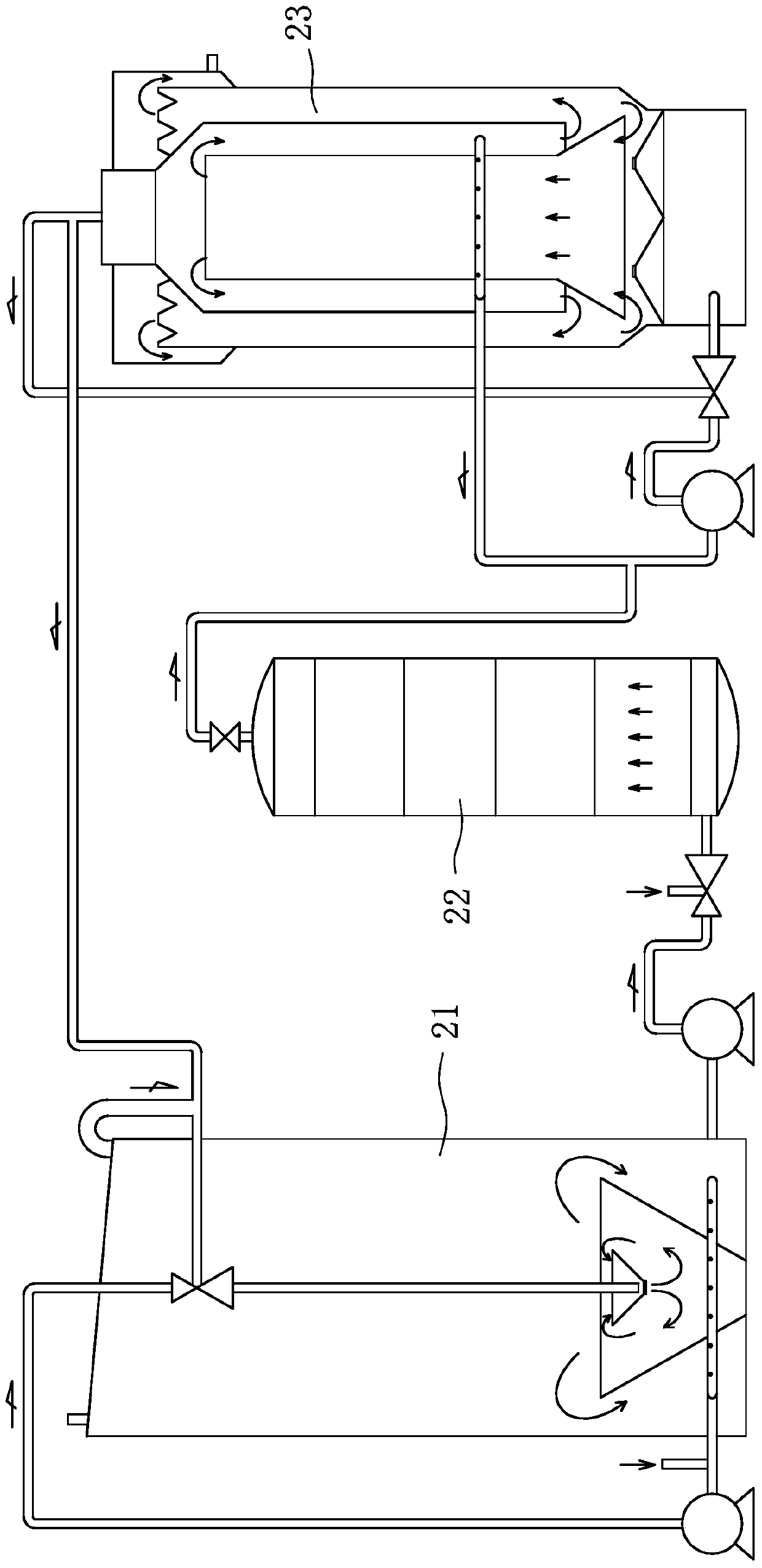

[0023] refer to figure 1 and figure 2 , the lysis step 11 is to use ozone and water power to destroy the cell walls of microorganisms contained in a biological sludge in a confined space 21, so as to change the physical and chemical characteristics of the biological sludge. After the biological sludge is refined by means of hydraulic circulation oscillation, the biological sludge can be refined into fine particles with a particle size of 0.3 mm to 0.6 mm, which greatly increases the specific surface area. Then, in a contact space 22, it is mixed and contacted with ozone inhaled under negative pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com