Construction Method of Cast-in-place Pile Using Extended Double-layer Reinforcement Cage

A double-layer steel cage and construction method technology, applied in the field of construction, can solve the problems that the pile length cannot be increased arbitrarily, affect the load-bearing performance of the pile, and increase the project cost, etc., so as to reduce the cost of piling construction, increase the bearing load, increase Effect of sidewall mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

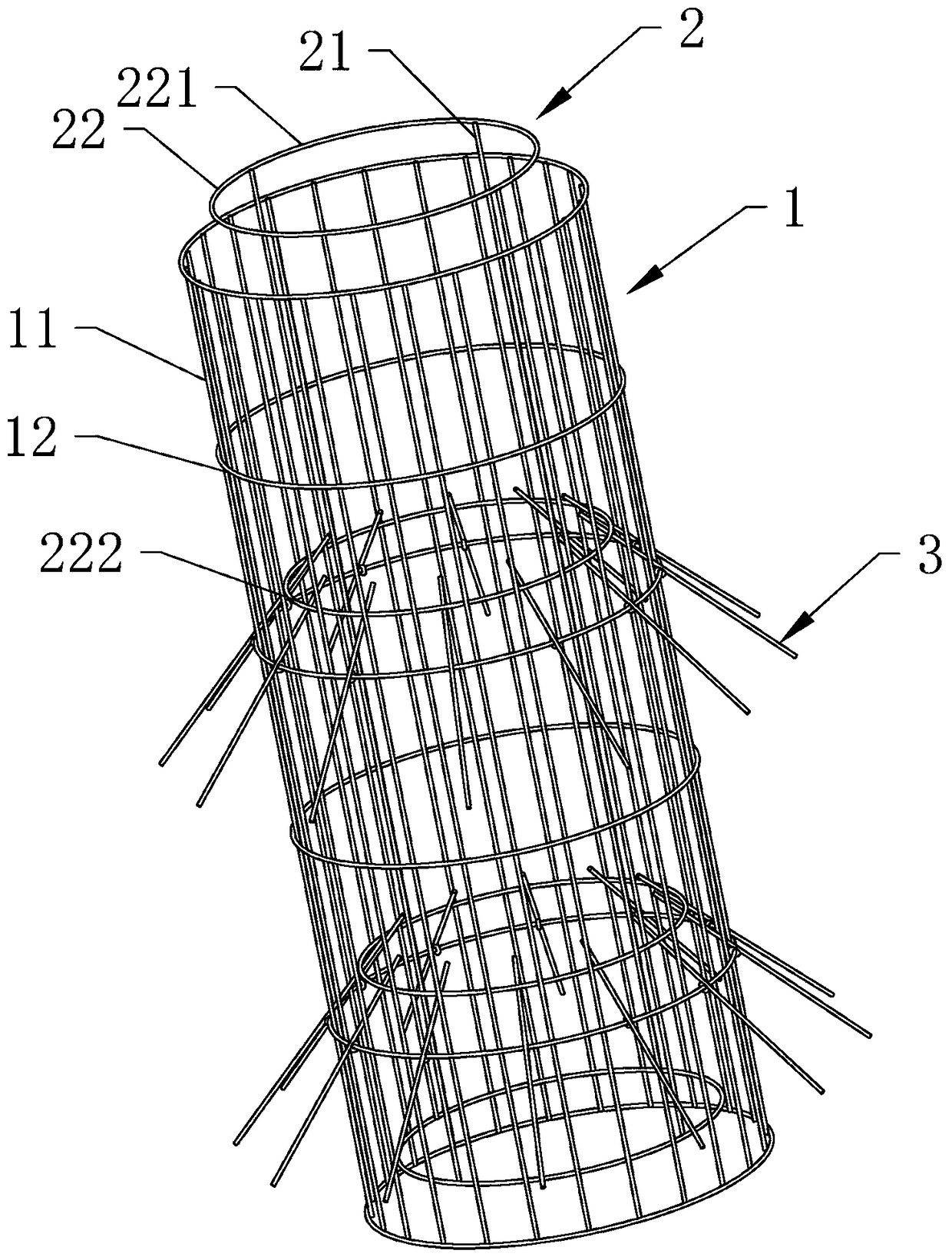

[0033] according to figure 1 , figure 2 As shown, the construction method of cast-in-situ piles made of extended double-layer steel cages includes the following steps:

[0034] Step 1, prepare the reinforcement cage: design and calculate the size of the reinforcement cage, and make the reinforcement cage according to the size;

[0035] The reinforcement cage includes an outer cage body 1, an inner cage body 2 and stretching ribs 3; the inner cage body 2 is arranged in the inner space surrounded by the outer cage body 1, and has the function of moving axially along the reinforcement cage body, and the outer cage body 1 includes the main reinforcement 11 of the outer cage and the stirrup 12 of the outer cage. The inner cage body 2 includes the main reinforcement 21 of the inner cage and the stirrup 22 of the inner cage. Respectively, the extension section 31 extending from the top of the stretching rib 3 to the outside of the outer cage body 1 and the positioning section 33 w...

Embodiment 2

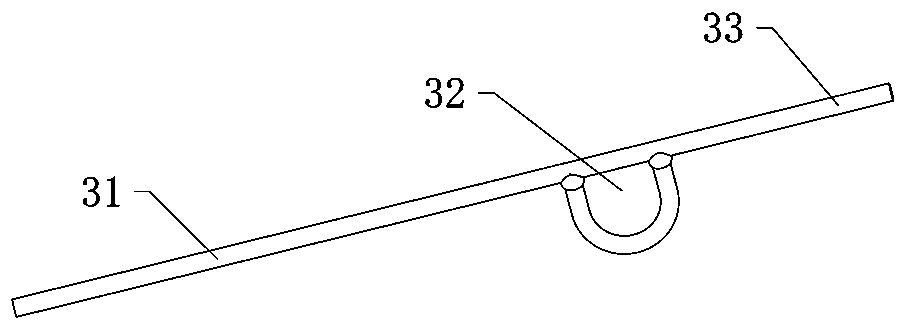

[0044] The difference from the above-mentioned embodiment 1 is that, according to image 3 As shown, the connecting section 32 is a split ring structure, and the two ends of the split ring are respectively connected with the extension section 31 and the positioning section 33. The preparation method of the stretching rib 3 is as follows: take a straight steel bar, and bend one end thereof into an opening ring structure.

Embodiment 3

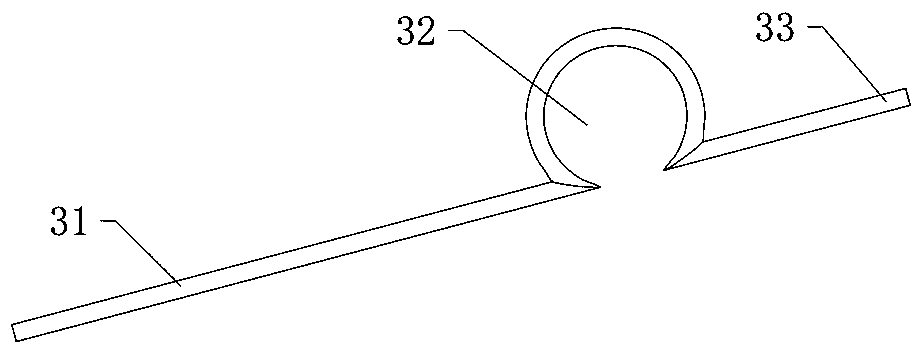

[0046] The difference from the above-mentioned embodiment 1 is that, according to Figure 4 As shown, the connecting section 32 is a helical coil, and the two ends of the helical coil are respectively connected with the extension section 31 and the positioning section 33. The preparation method of the stretching rib 3 is as follows: take a straight steel bar and bend it in a spiral manner, and the curved part forms Connection section 32.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com