Double-row full-ball self-aligning ball bearing with large self-aligning angle

A self-aligning ball bearing and center angle technology, which is applied to the direction of rotating bearings, bearings, bearing components, etc., can solve the problems of large operating angle, small self-aligning angle range, and inability to meet low starting torque, so as to ensure the sealing performance , Guaranteed bearing capacity, simple and flexible structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

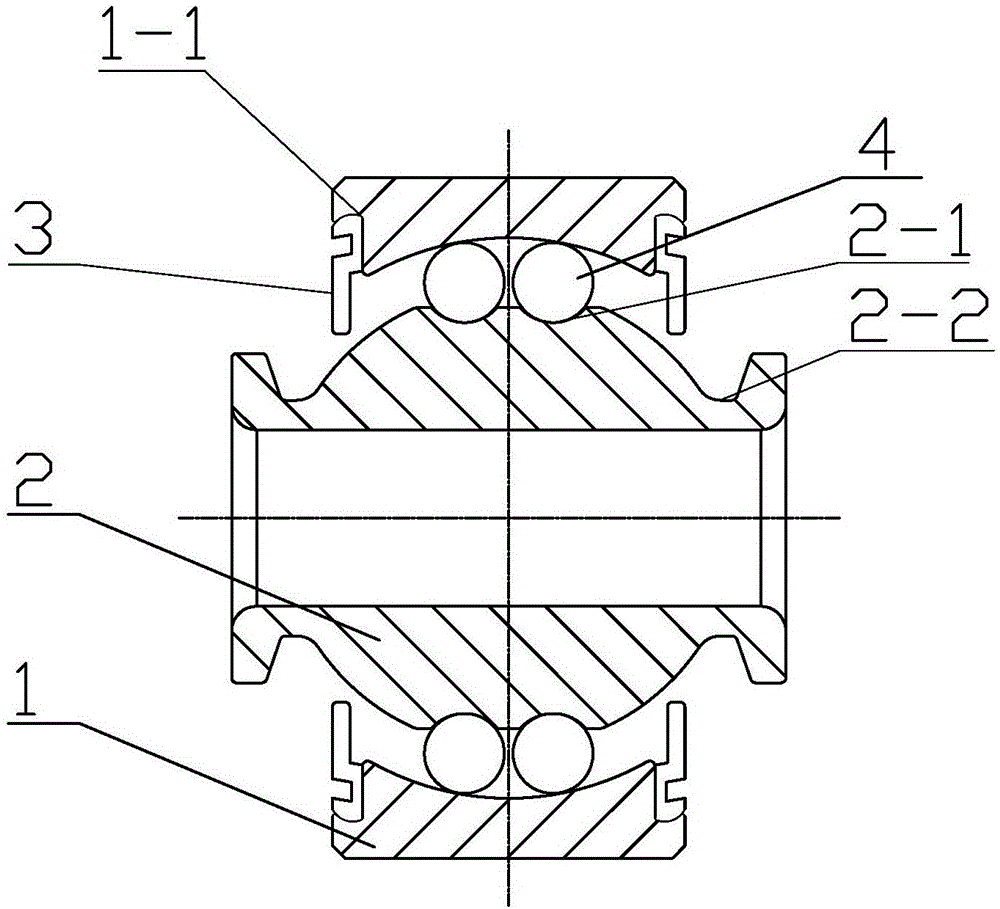

[0019] Specific implementation mode one: combine figure 1 with figure 2 Describe this embodiment, a double-row full-spherical self-aligning ball bearing with a large self-aligning angle in this embodiment, which includes an outer ring 1, an inner ring 2, two dust covers 3 and several rolling elements 4, the inner ring The cross section of the middle part of the outer diameter surface of 2 and the cross section of the inner diameter surface of outer ring 1 are arc-shaped, and the center of curvature of the inner diameter surface of outer ring 1 and the middle part of the outer diameter surface of inner ring 2 are consistent, and the outer diameter surface of inner ring 2 is along the Two annular raceways 2-1 are arranged side by side in the circumferential direction, and the two annular raceways 2-1 are arranged symmetrically with respect to the radial center line of the inner ring 2, and several rolling elements 4 are closely arranged on the two annular raceways 2-1. 1, the ...

specific Embodiment approach 2

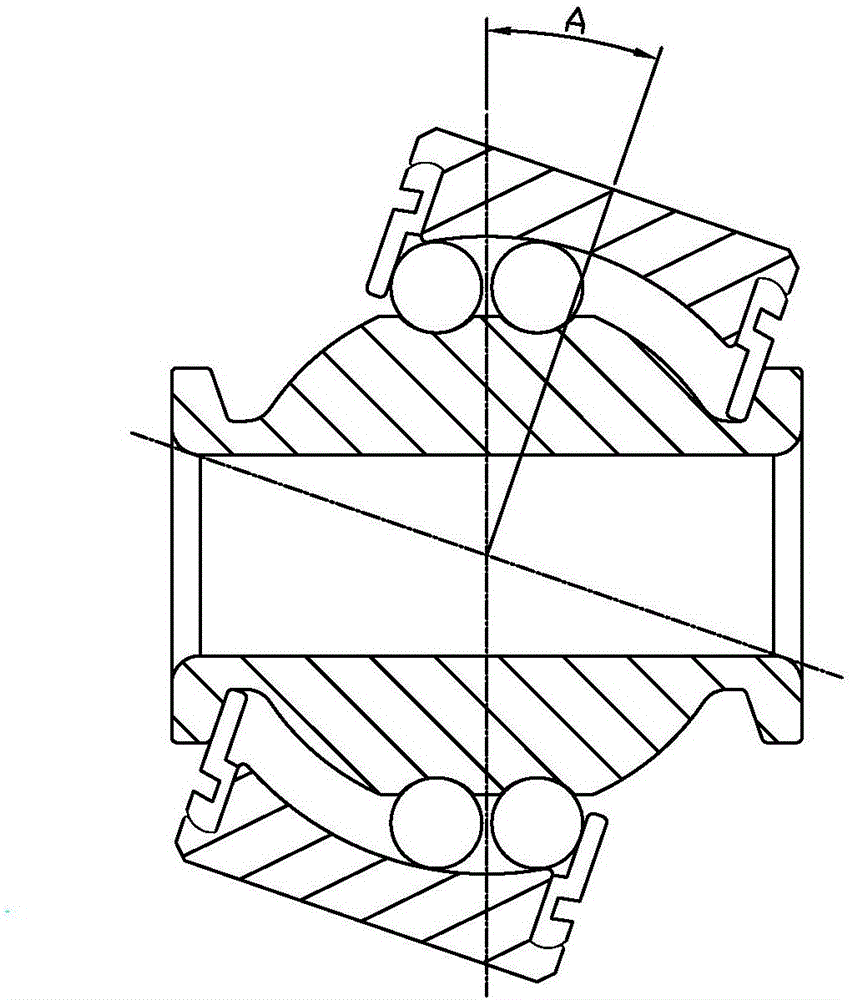

[0022] Specific implementation mode two: combination figure 1 with figure 2 To describe this embodiment, the single-side maximum self-aligning angle A of the bearing is 19°. With this design, the maximum self-aligning angle A of the bearing is related to the diameter and axial width of the outer diameter surface of the inner ring 2 of the bearing, and the diameter and axial width of the inner diameter surface of the outer ring 1. The inner diameter of the outer ring is 22mm, and the outer diameter of the inner ring is 18.24mm, the axial width of the inner diameter surface of the outer ring is 10.9-11.1mm, and the axial width of the middle part of the outer diameter surface of the inner ring is 15.84-15.86mm. Other compositions and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0023] Specific implementation mode three: combination figure 1 with figure 2 To illustrate this embodiment, the two ends of the outer ring 1 are symmetrically provided with a groove 1-1 with a cross section of "7" shape, and the side wall of the groove 1-1 is arranged perpendicular to the central axis of the bearing, and, The other side wall of the groove 1-1 is arc-shaped, and the dust cover 3 is clamped in the groove 1-1. With this design, the dust cover 3 is fixedly connected with the grooves 1-1 at both ends of the outer ring 1, and adopts a non-contact seal with a dust-proof function, which can prevent impurities from entering the bearing and causing damage to the bearing when the bearing is running under special working conditions. When the bearing does not run normally, it will break down. The structure is simple, the installation is firmer, and the sealing effect is better; . Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com