Micro accelerator and manufacturing method thereof

A technology of micro-accelerometer and cover plate, which is applied in the direction of measuring acceleration, velocity/acceleration/impact measurement, and measuring devices, etc. It can solve the problems of micro-accelerometer measurement result drift, cantilever beam occupying too much space, and size is not large enough, etc. Achieve the effects of small temperature effect, small detection modal stiffness and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

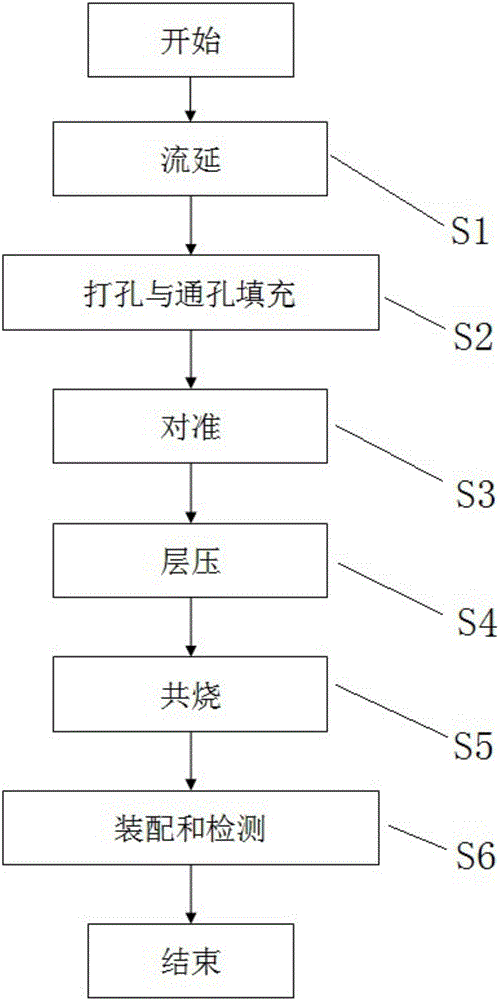

[0016] The following will be further described in detail through specific embodiments in conjunction with the accompanying drawings.

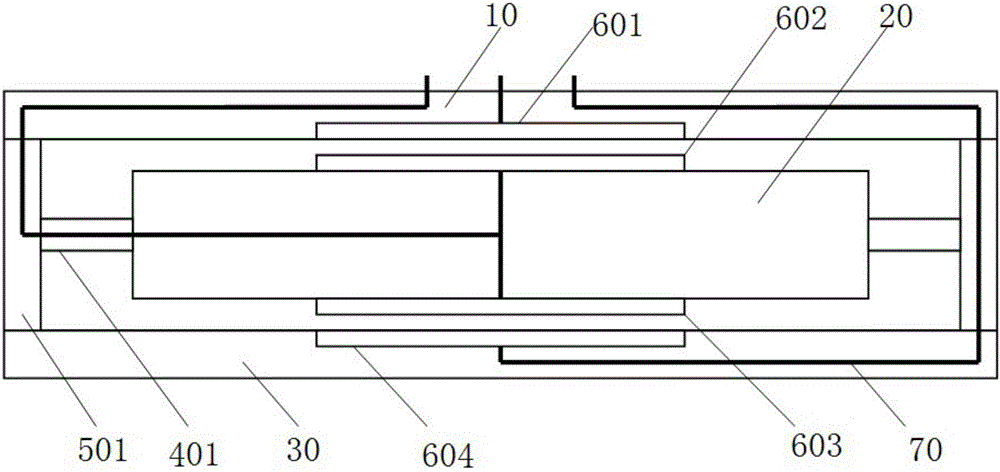

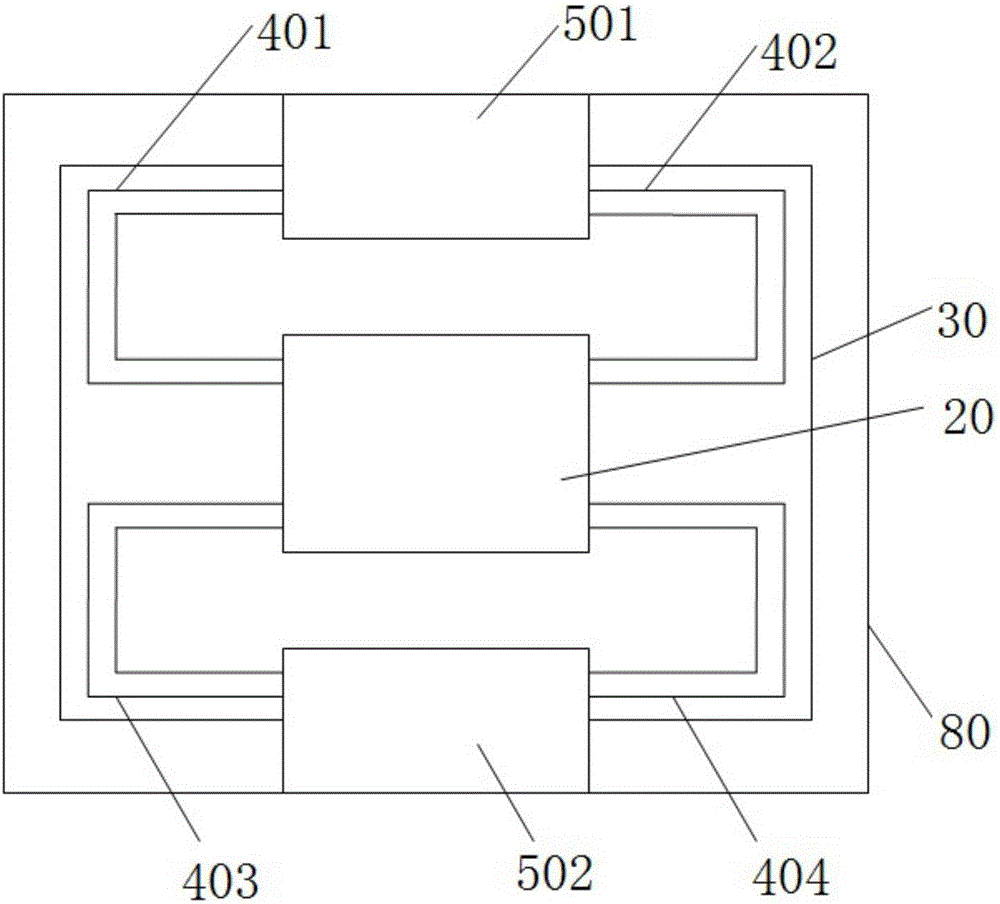

[0017] Such as figure 1 with figure 2 As shown, the present embodiment discloses a micro accelerometer, which mainly includes an upper cover plate 10, a mass block 20, a lower cover plate 30, a first cantilever beam 401, a second cantilever beam 402, a third cantilever beam 403, a Four cantilever beams 404 , a first surrounding frame 501 , a second surrounding frame 502 , and a housing 80 .

[0018] The upper cover 10 is opposite to the lower cover 30 to form a space.

[0019] The first surrounding frame 501 is opposite to the second surrounding frame 502 for supporting the upper cover 10 and the lower cover 30 . One end of the first surrounding frame 501 is connected to the edge of the lower surface of the upper cover plate 10, and the other end is connected to the edge of the upper surface of the lower cover plate 30. Here, the lower surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com