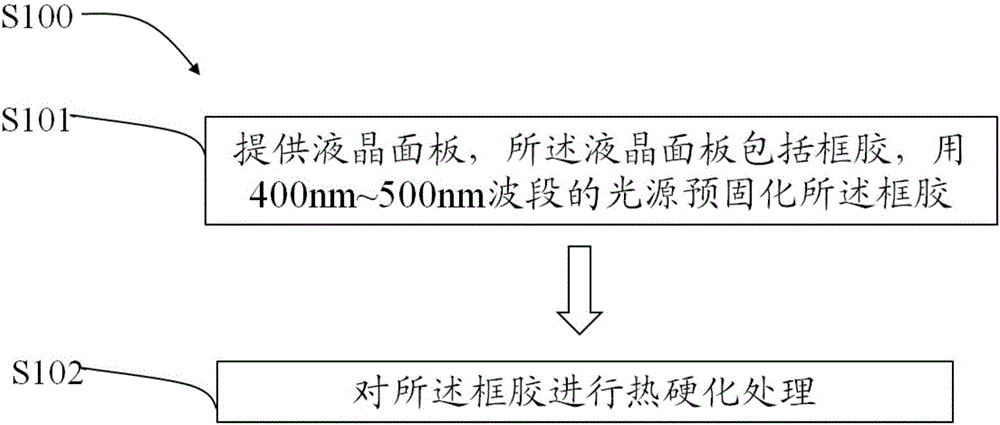

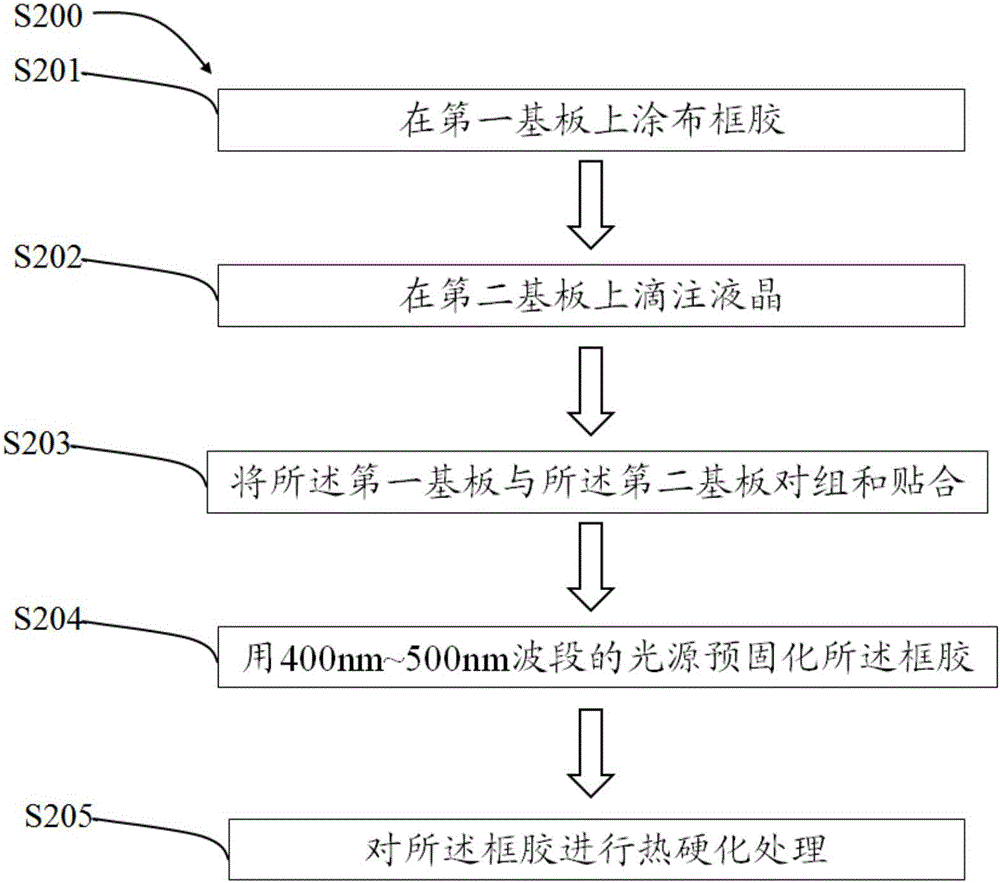

Sealant curing method and liquid crystal panel manufacturing method

A liquid crystal panel and curing method technology, applied in nonlinear optics, instruments, optics, etc., can solve the problems of reduced curing rate of sealant, human skin damage, low curing rate of visible light sealant, etc. Effect of cure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

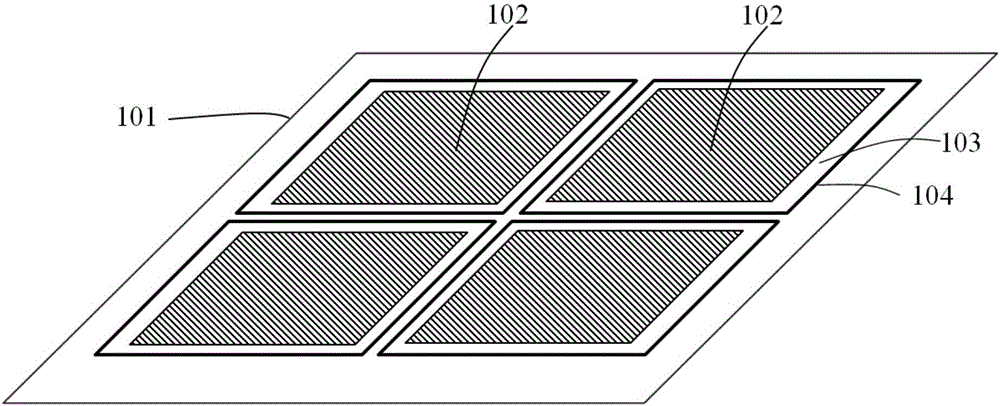

Image

Examples

Embodiment 1

[0042] Provide a liquid crystal panel, the liquid crystal panel includes a frame glue, use an ultraviolet light filter to filter the ultraviolet light and visible light below 430nm in the visible light lamp in the 380-800nm band, and obtain the visible light in the 430-800nm band, and use the above-mentioned visible light to comprehensively carry out the liquid crystal panel The irradiation, the visible light intensity is 120mW / cm 2 , After a curing time of 30 to 100 seconds. The curing rate of the frame glue of the liquid crystal panel in this embodiment was tested after photocuring, and the curing rate of the liquid crystal panel was less than 30%.

Embodiment 2

[0044] A liquid crystal panel is provided, the liquid crystal panel includes frame glue, ultraviolet light and visible light below 400nm in a visible light lamp in the 380-800nm band are filtered by an ultraviolet filter, and visible light above 500nm is filtered by an optical filter to obtain a light in the 400-500nm band Visible light, and the light intensity is concentrated in the 420-500nm band, using the above visible light to fully irradiate the liquid crystal panel, the visible light intensity is 120mW / cm 2 , After a curing time of 30 to 100 seconds. The curing rate of the sealant of the liquid crystal panel in this embodiment was tested after light curing, and the curing rate of the liquid crystal panel was 46%.

Embodiment 3

[0046] A liquid crystal panel is provided, the liquid crystal panel includes frame glue, ultraviolet light and visible light below 400nm in visible light lamps with a wavelength of 380 to 800nm are filtered by an ultraviolet filter, and visible light above 450nm is filtered by an optical filter to obtain light in a wavelength range of 400 to 450nm Visible light, and the light intensity is concentrated in the 400-430nm band, using the above visible light to fully irradiate the liquid crystal panel, the visible light intensity is 120mW / cm 2 , After a curing time of 30 to 100 seconds. The curing rate of the sealant of the liquid crystal panel in this embodiment was tested after photocuring, and the curing rate of the liquid crystal panel was 51%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap