Movable platform movement control method based on load center of gravity

A motion control, mobile platform technology, applied in non-electric variable control, two-dimensional position/channel control, control/regulation system, etc., can solve the problems of inflexible control strategy, ignoring load, loss of stability of load, etc. Achieve the effect of improving handling efficiency, convenient control and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

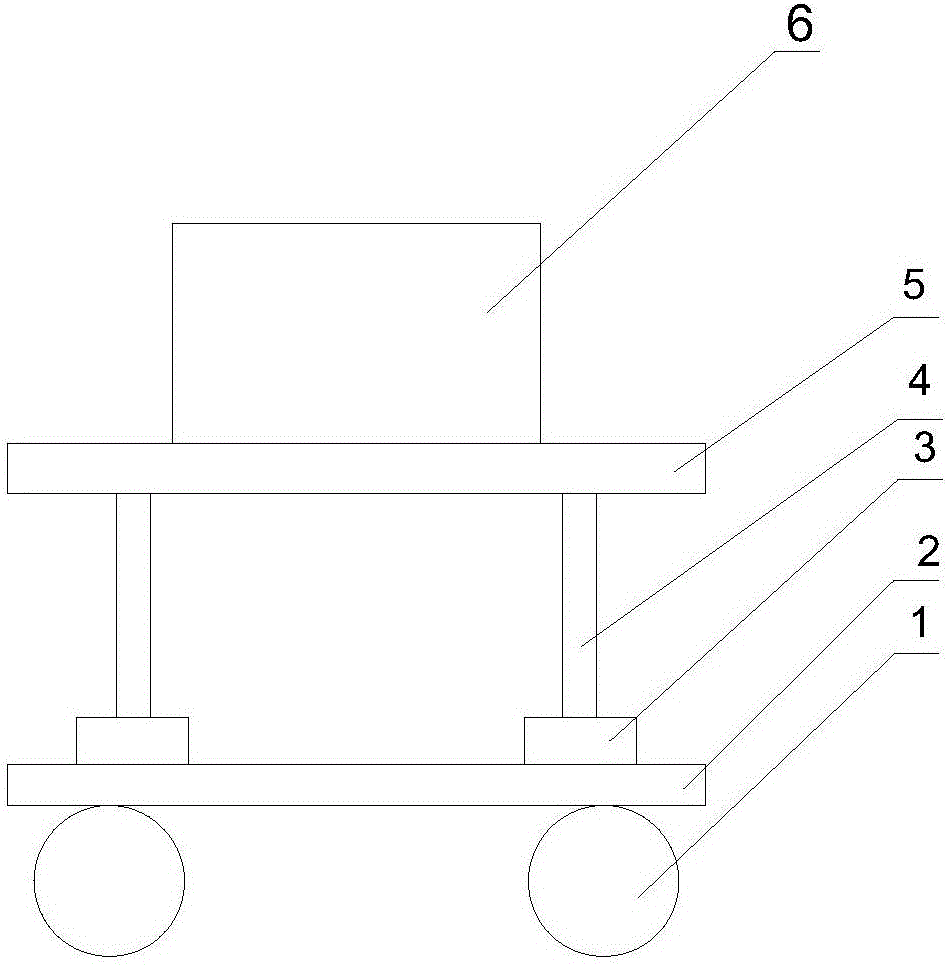

[0063] Taking the movable platform with 3 load cells as an example, the specific implementation is as follows:

[0064] Set the load cell 3 to zero so that its measured value is 0 when it is empty.

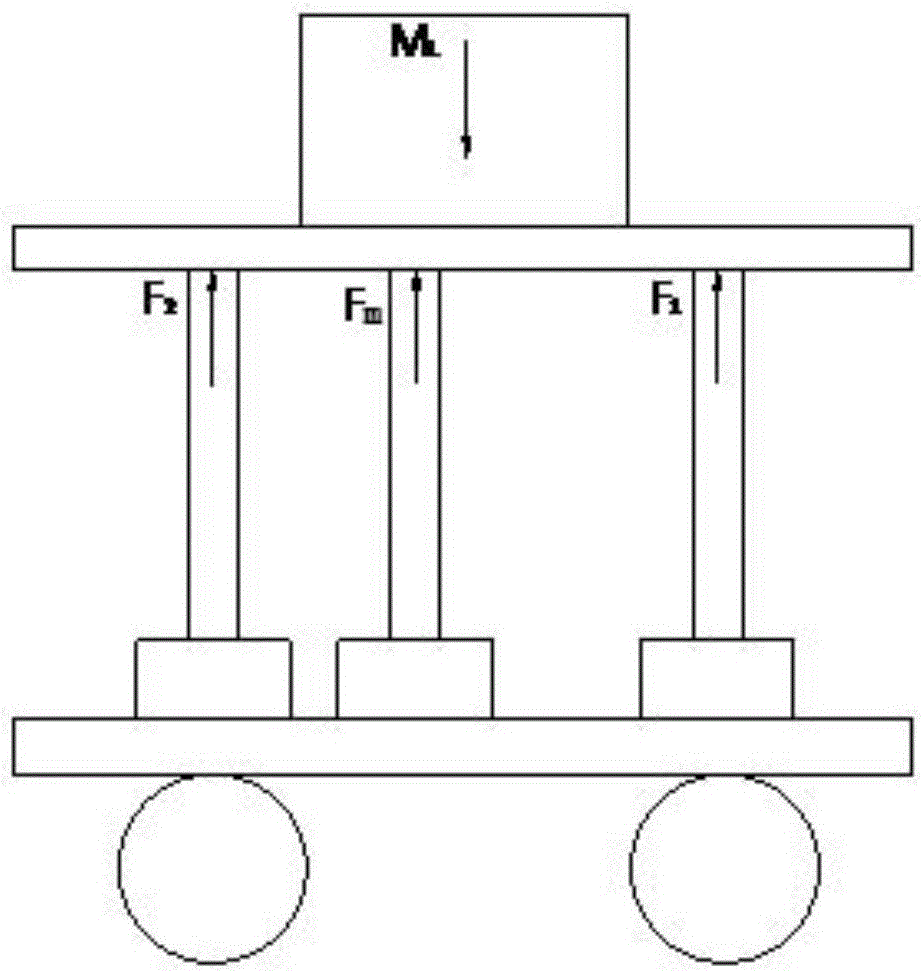

[0065] The movable platform carries the load 6, assuming that when the mass of the load 6 is M L , the pressure point N 1 , N 2 , N 3 The corresponding values of the load cell 3 are F1, F2, F3. Depend on image 3 According to the vertical direction, the force balance can be obtained as:

[0066] m L g=F 1 +F 2 +F 3

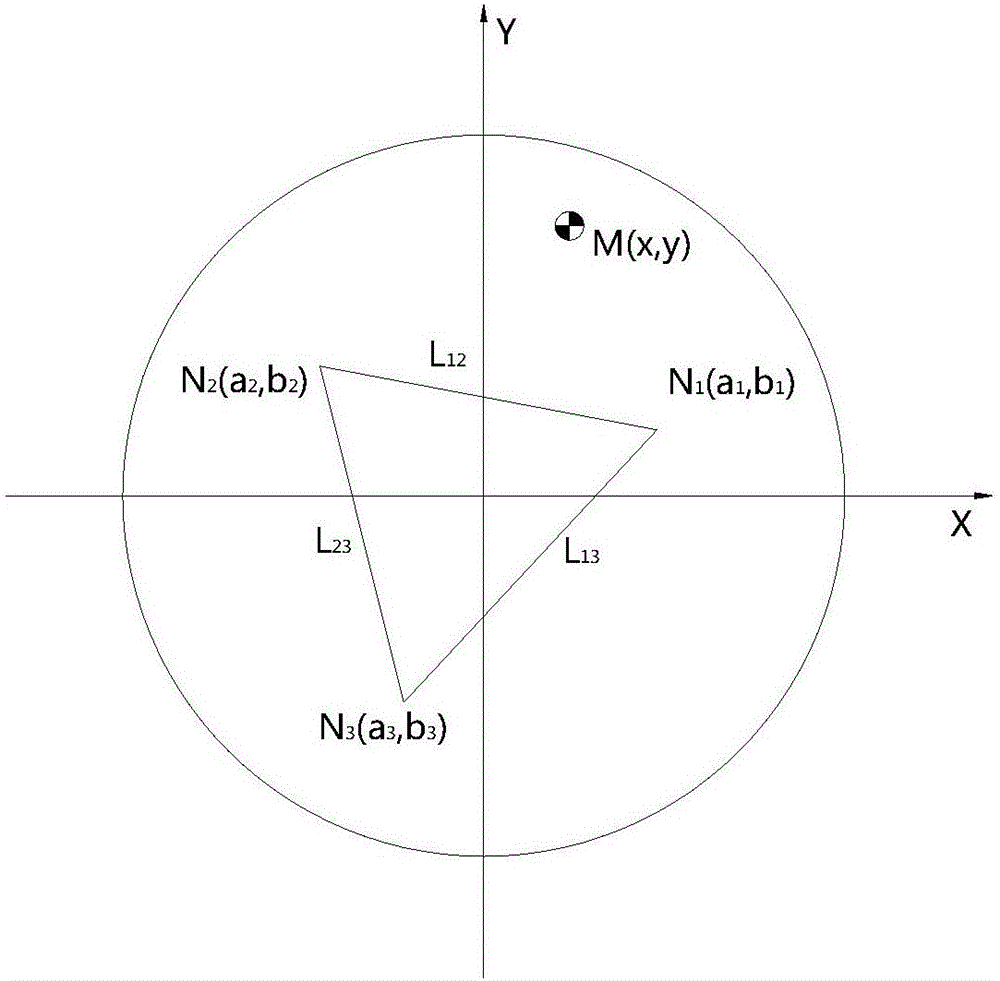

[0067] Another N 1 , N 2 The distance between 12 , N 2 , N 3 The distance between 23 , N 1 , N 3 The distance between 13 ,

[0068] in:

[0069]

[0070]

[0071]

[0072] respectively for point N 1 , N 2 , N 3 Take the moment, according to the moment balance:

[0073]

[0074]

[0075]

[0076] According to the above formula, it can be obtained:

[0077]

[0078]

[0079] When the motion track of the movable platfor...

Embodiment 2

[0084] Taking the movable platform with 3 load cells as 4 as an example, Figure 7 It is a schematic diagram of the projection position of the center of gravity of the load 6 and the projection position of the load cell 3 on the circular tray 5 when the movable platform has 4 load cells 3 , Figure 8 It is a schematic diagram of the force balance of the load 6 carried by the movable platform with 4 load cells 3; the specific implementation is as follows:

[0085] Set the load cell 3 to zero so that its measured value is 0 when it is empty.

[0086] The movable platform carries the load 6, assuming that when the mass of the load 6 is M L , point N 1 ~N 4 The corresponding value of the load cell 3 is F1-F4. Depend on image 3 According to the vertical direction, the force balance can be obtained as:

[0087] m L g=F 1 +F 2 +F 3 +F 4

[0088] respectively for point N 1 , N 2 , N 4 Take the moment, according to the moment balance:

[0089]

[0090]

[0091] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com