Clearance adjusting mechanism for stator and rotor of electric vacuum pump

A gap adjustment mechanism and technology of gap adjustment, which are applied in the direction of centering/balancing rotors, etc., can solve the problems of cumbersome stator and rotor, affecting production rhythm, etc., and achieve the effect of improving production takt, novel structure and simplifying assembly process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

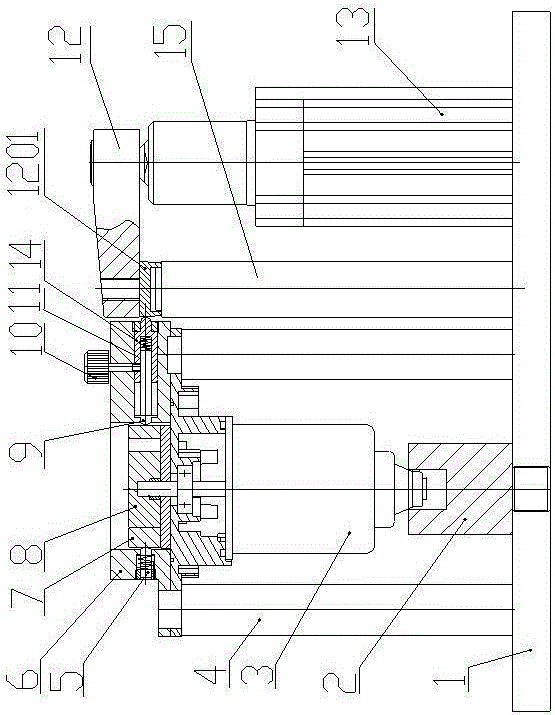

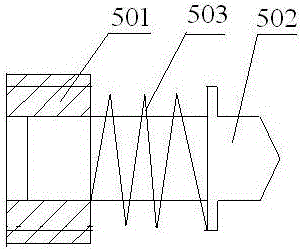

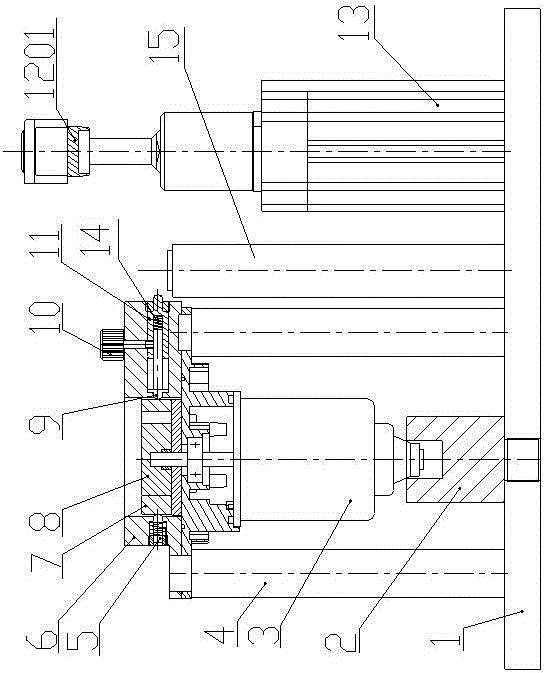

[0010] The base 1 is fixedly connected to the motor base 2, the motor bracket 4, the rotary cylinder 13 and the gap adjustment head limit seat 15, the bottom of the motor body 3 is placed on the motor base 2, and the upper flange is placed on the motor bracket 4, The bottom of the tire 6 is placed on the motor bracket 4 and above the motor flange, the rotor 8 is connected with the motor output shaft, the stator 7 is placed between the tire 6 and the rotor 8, and the tire 6 and the stator 7 have an adjustment gap, One side of the tire 6 is equipped with a spring self-adjusting rod device 5, and the other side is equipped with an error canceling rod 9 and a gap adjusting rod 11. The error canceling rod 9 is inserted into the gap adjusting rod 11, and there is a spring one 14 between the two. The locking screw 10 is connected with the gap of the tire 6, the lower part is threaded with the gap adjustment rod 11, and the bottom is connected with the error elimination rod 9. The top ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com