Sealing method for heat conducting components

A technology of heat-conducting components and components, applied in the construction of components of electrical equipment, modification through conduction heat transfer, electrical components, etc., can solve problems such as circuit short circuit and leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

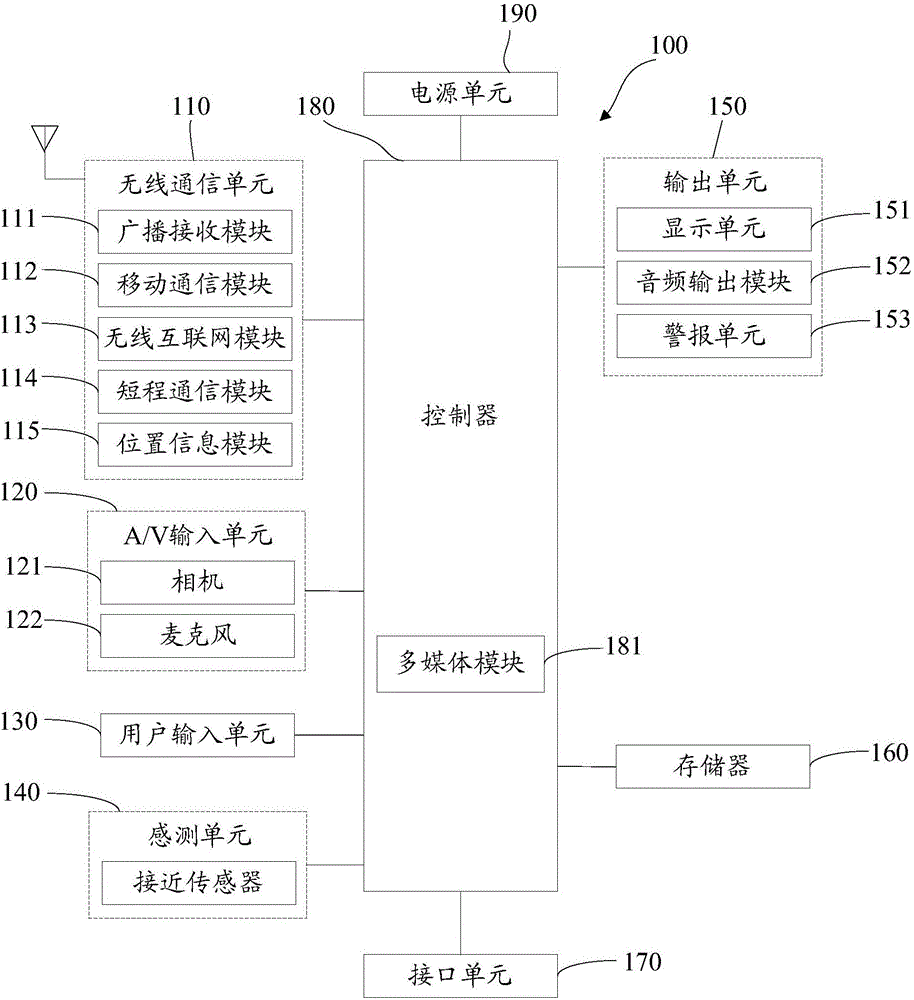

[0082] The embodiment of the present invention proposes a mobile terminal. A schematic diagram of the hardware structure of the mobile terminal is as figure 1 Shown.

[0083] When the first heat conducting component is arranged on the chip, it contacts the chip and surrounds the chip.

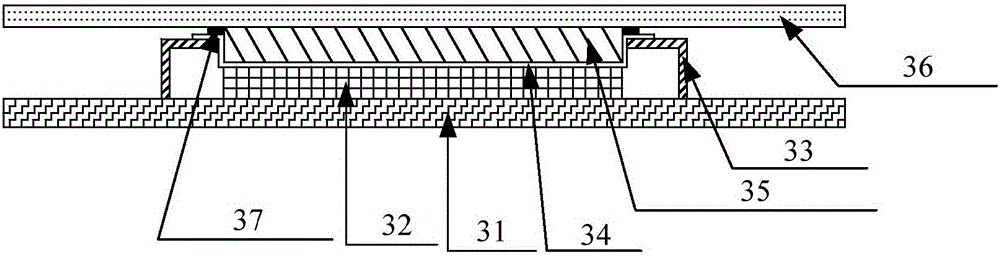

[0084] In this embodiment, as image 3 As shown, the mobile terminal includes:

[0085] PCB 31;

[0086] The chip 32 is fixed on the PCB 31, and the chip 32 can generate heat during operation;

[0087] The shielding cover 33 is fixed to the PCB 31 and surrounds the chip 32, and the shielding cover 33 is provided with a through hole;

[0088] A first heat conducting component 34, sealing the through hole, and forming a groove at the through hole, and the bottom of the groove is in contact with the surface of the chip 32;

[0089] The second heat conducting component 35 is filled in the groove; the second heat conducting component 35 is a metallic phase change material;

[0090] The heat-conducting middle fra...

Embodiment 2

[0116] The embodiment of the present invention proposes a mobile terminal. A schematic diagram of the hardware structure of the mobile terminal is as figure 1 Shown.

[0117] When the first heat conducting component is arranged on the chip, it contacts the chip and surrounds the chip.

[0118] In this embodiment, as image 3 As shown, the mobile terminal includes:

[0119] PCB 31;

[0120] The chip 32 is fixed on the PCB 31, and the chip 32 can generate heat during operation;

[0121] The shielding cover 33 is fixed to the PCB 31 and surrounds the chip 32, and the shielding cover 33 is provided with a through hole;

[0122] A first heat conducting component 34, sealing the through hole, and forming a groove at the through hole, and the bottom of the groove is in contact with the surface of the chip 32;

[0123] The second heat conducting component 35 is filled in the groove; the second heat conducting component 35 is a metallic phase change material;

[0124] The heat-conducting middle fra...

Embodiment 3

[0159] Based on the mobile terminal provided in the first embodiment of the present invention, this embodiment provides a method for sealing a thermally conductive component, such as Figure 4 As shown, the method includes the following steps:

[0160] Step 401: Fix a shielding cover provided with a through hole on the PCB where the chip is fixed, and surround the chip;

[0161] Here, the chip can generate heat during operation.

[0162] In an embodiment, the method may further include:

[0163] The chip is fixed on the PCB by means of patch.

[0164] Among them, in practical applications, the most commonly used patching method is: soldering the chip on the PCB by using solder bars (wires) or the like.

[0165] Correspondingly, the shielding cover can be fixed on the PCB by means of patches.

[0166] In practical applications, through holes can be formed on the shielding cover by stamping.

[0167] In practical applications, the chip may generally be a CPU or the like.

[0168] The shieldin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com