Method for evaluating weatherability of fluorinated coating film

An evaluation method and weather resistance technology, applied in the direction of weather resistance/light resistance/corrosion resistance, measuring devices, instruments, etc., can solve the problems of slow deterioration of test pieces and long time for weather resistance evaluation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

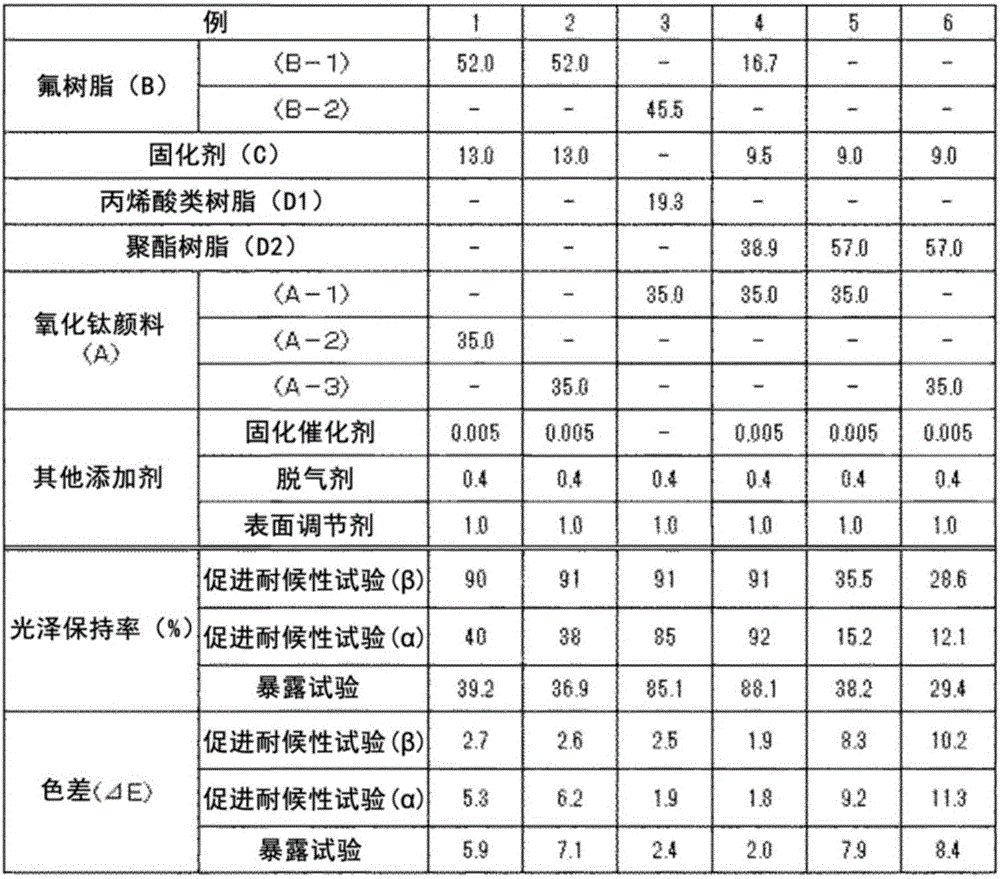

[0091] The present invention will be described in detail below with reference to examples, but the present invention is not limited to these examples.

example 1、2 and 4~6

[0142] Using a high-speed mixer (manufactured by Yuzaki Co., Ltd.), the components described in Table 1 were mixed in the stated parts by mass for about 10 to 30 minutes to obtain a powdery mixture. This mixture was melt-kneaded at a cylinder set temperature of 120° C. using a twin-screw extruder (manufactured by ThermoPrism Ltd., 16 mm extruder) to obtain powder pellets. Next, the obtained particles were pulverized at room temperature using a pulverizer (manufactured by FRITSCH, rotor speed mill P14), and classified with a 150-mesh sieve to obtain a powder coating having an average particle diameter (50% average volume particle size distribution) of about 40 μm. .

[0143] Using an electrostatic coating machine (manufactured by Onoda Cement Co., Ltd., GX3600C), the obtained powder paint was electrostatically coated on a chromated aluminum plate (length x width 75 mm x 150 mm, thickness 1 mm). On one side, it was kept in an atmosphere at 200° C. for 20 minutes. Thereafter, i...

example 3

[0145] (Manufacture of acrylic resin (D1))

[0146]200 mL of deionized water, 2 g of a reactive emulsifier (manufactured by Sanyo Chemical Industry Co., Ltd., ELEMINOL (trade name) JS-2, a succinate derivative) were introduced into a four-neck flask with an inner capacity of 1 L equipped with a cooling tube and a thermometer. and 2 g of polyoxyethylene nonylphenyl ether (addition of 10 moles of ethylene oxide). Under a nitrogen stream, 20 mL of a 2 mass % aqueous solution of ammonium persulfate was added when the temperature reached 80° C. in the warm bath. Next, a mixture of 140.2 g of methyl methacrylate, 80.0 g of ethyl methacrylate, and 0.2 g of n-lauryl mercaptan as a chain transfer agent was added dropwise over 1 hour. Next, 2 mL of a 2% by mass aqueous solution of ammonium persulfate was added to start the reaction. After 3 hours, the temperature in the flask was raised to 85°C and maintained for 1 hour. Thereafter, filtration was performed through a 300-mesh wire me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com