Multifunctional floor brush

A multi-functional, ground-based technology, applied in the direction of the suction nozzle, can solve the problems of easily scratching the floor, poor air permeability, and large vacuum at the air inlet position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing and specific embodiment the present invention will be further described:

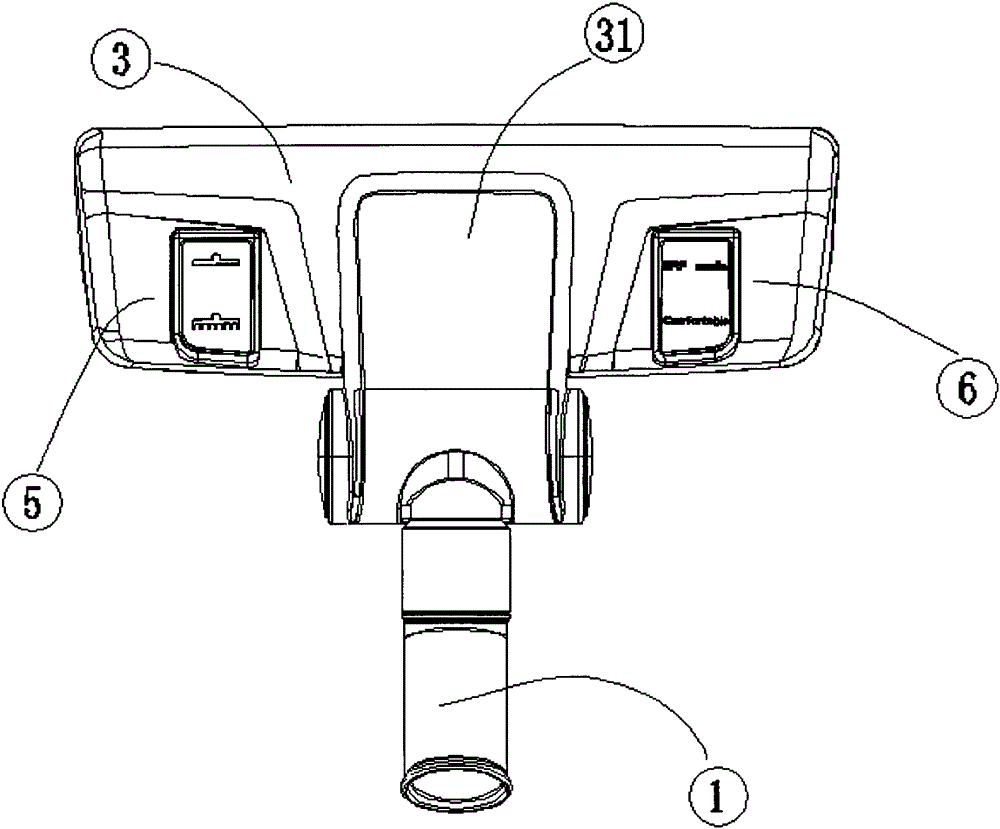

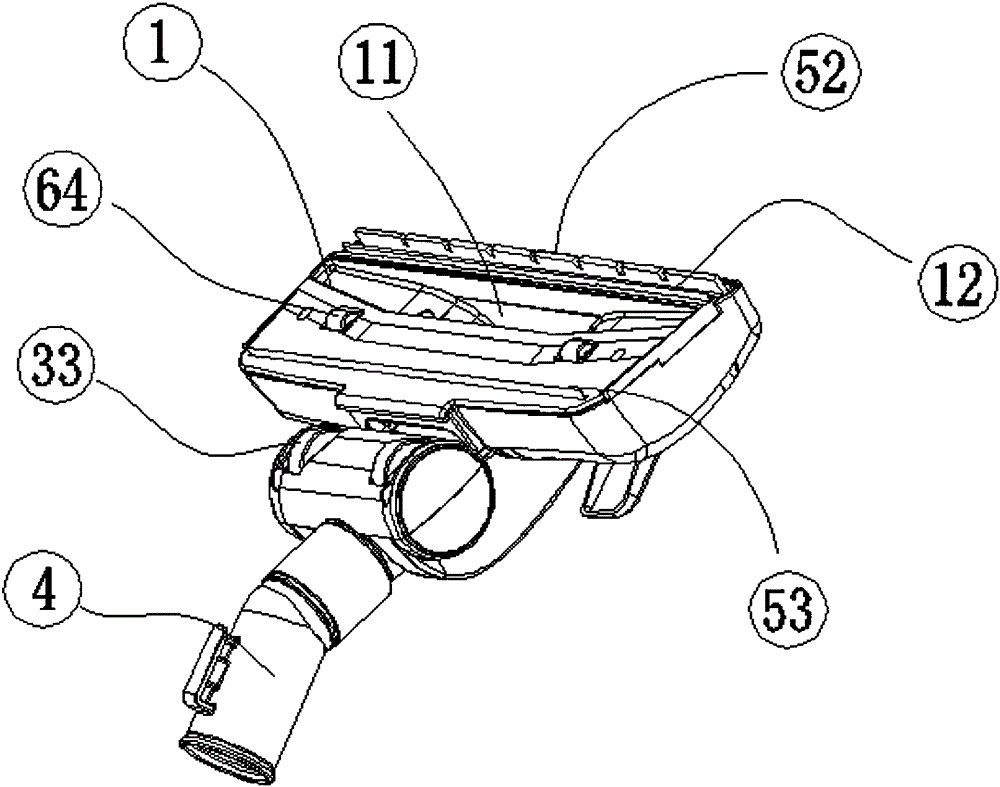

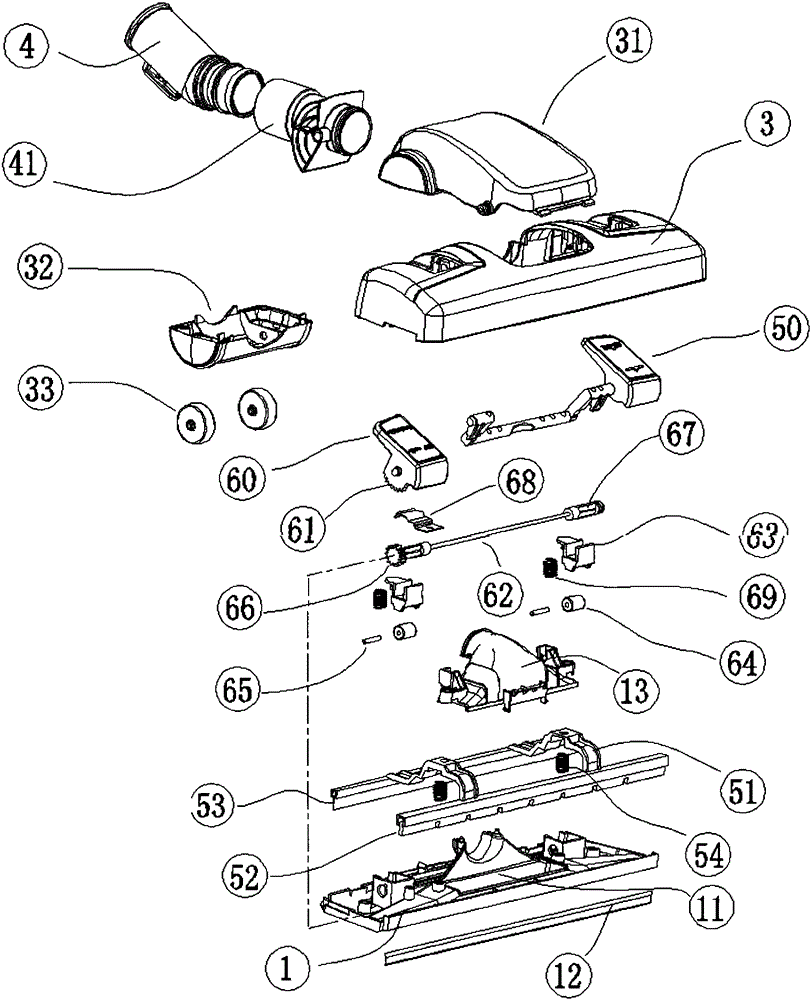

[0031] Example: such as figure 1 , figure 2 The multifunctional ground brush shown includes a ground brush surface cover 3, a ground brush bottom plate 1, and an air inlet 11 provided on the ground brush bottom plate 1 through which dust-laden air flow flows in, and is used to connect the ground brush connecting pipe 4 of the vacuum cleaner. The brush strip (front) 52 and the brush strip (rear) 53 for scraping the ground dust are arranged near the air inlet 11, and the first brush strip (front) 52 and brush strip (rear) 53 to move up and down are driven. A lifting structure 5, and a second lifting structure 6 for lifting the ground brush bottom plate 1 and changing the distance between the ground brush bottom plate 1 and the ground 9 to be cleaned. In this embodiment, the brush bar is set to two before and after, which are respectively a brush bar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com