Multifunctional protective cover for electrowelding

A protective cover, multi-functional technology, applied in eye mask, ophthalmic surgery and other directions, can solve the problem of toxic gas polluting the environment, affecting visual field observation, affecting welding speed and welding quality, etc., to reduce environmental pollution, reduce inconvenience, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

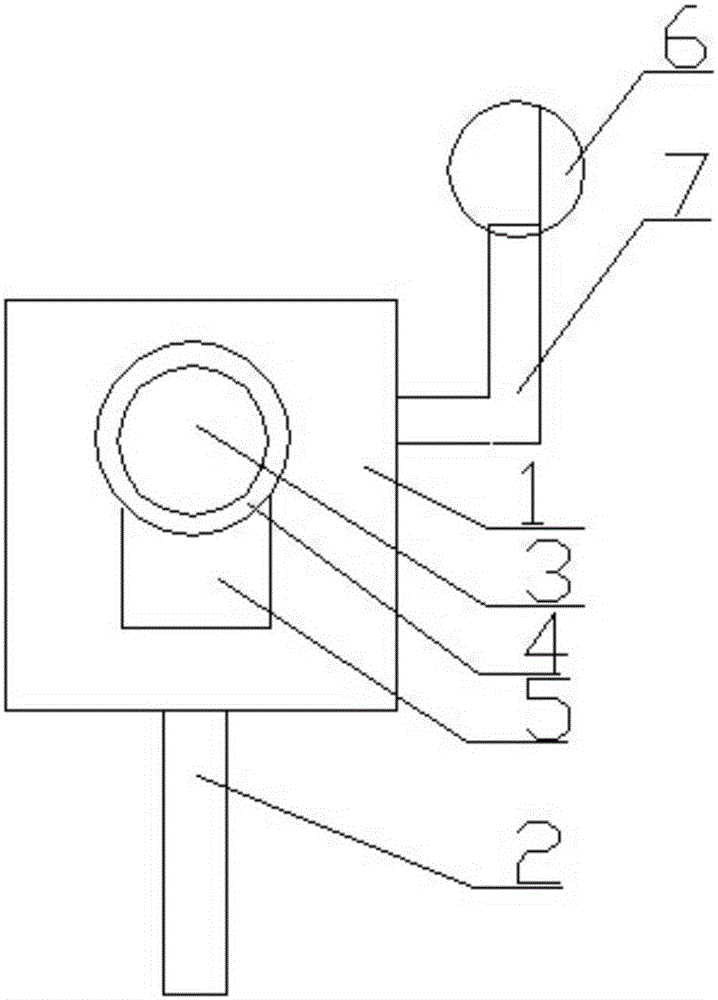

[0012] The present invention will be further described below in conjunction with accompanying drawing.

[0013] Such as figure 1 As shown, a protective cover for multifunctional electric welding includes a protective cover shell 1, a protective cover handle 2, and the protective cover handle 2 is arranged under the protective cover shell 1, and also includes a protective mirror 3 and a filter 6. The protective glasses 3 are installed on the protective cover shell 1, and the anti-fog plate 5 is installed under the protective glasses 3, and the filter 6 is connected with the protective cover shell 1 through the filter pipe 7.

[0014] Considering that the harmful gas will diffuse to the outside during the welding process, the filter tube 7 connected to the filter 6 is set as a sealed pipe, which can further ensure that the toxic gas is sealed in the sealed tube 7 and then disposed of in the filter 6 .

[0015] In order to prevent or avoid welding operators during the welding pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com