Rectifying-tower multilevel distributer for sassafras oil refinement

A rectifying tower and sassafras oil technology are applied in the field of multi-stage distributors of rectifying towers, which can solve the problem that the crude oil components of sassafras oil cannot be easily separated, etc., so as to increase the number of theoretical plates, improve separation efficiency, The effect of low resistance in the tower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

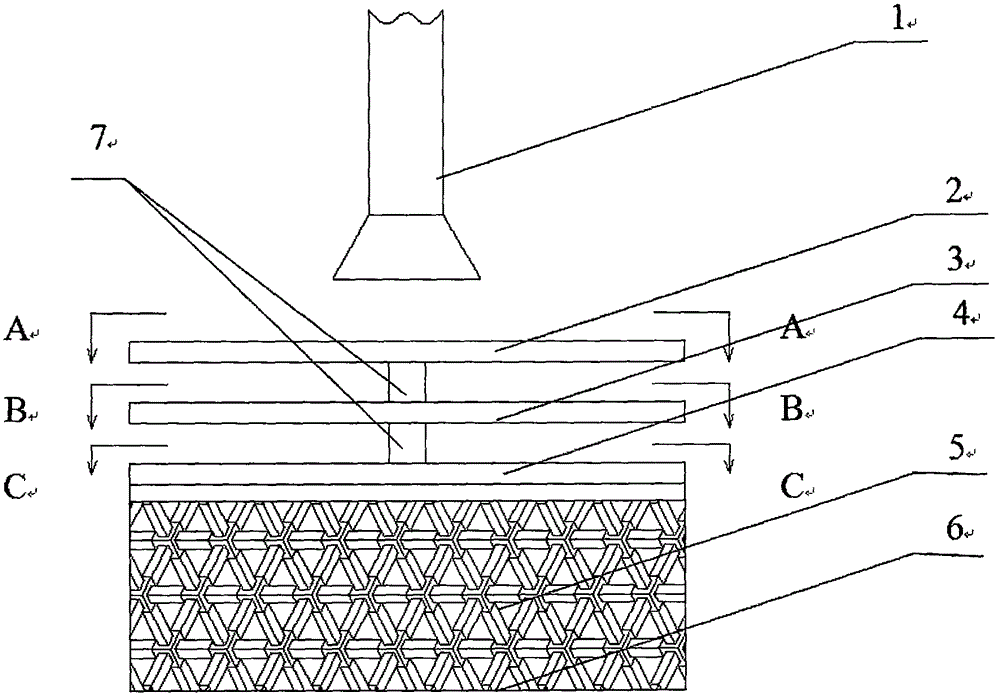

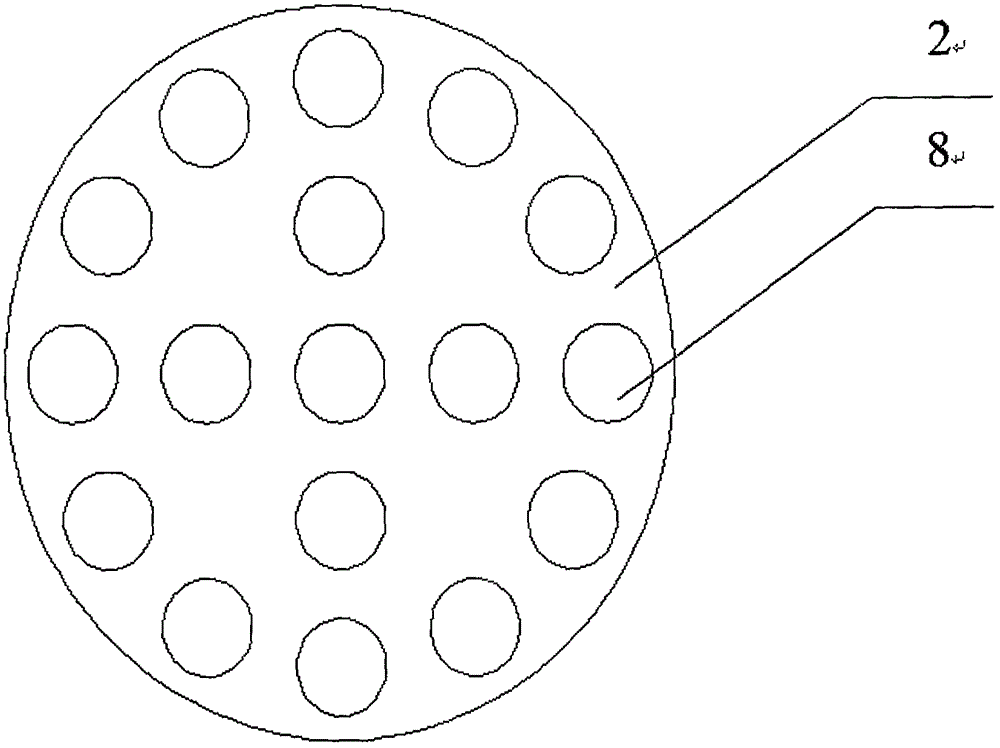

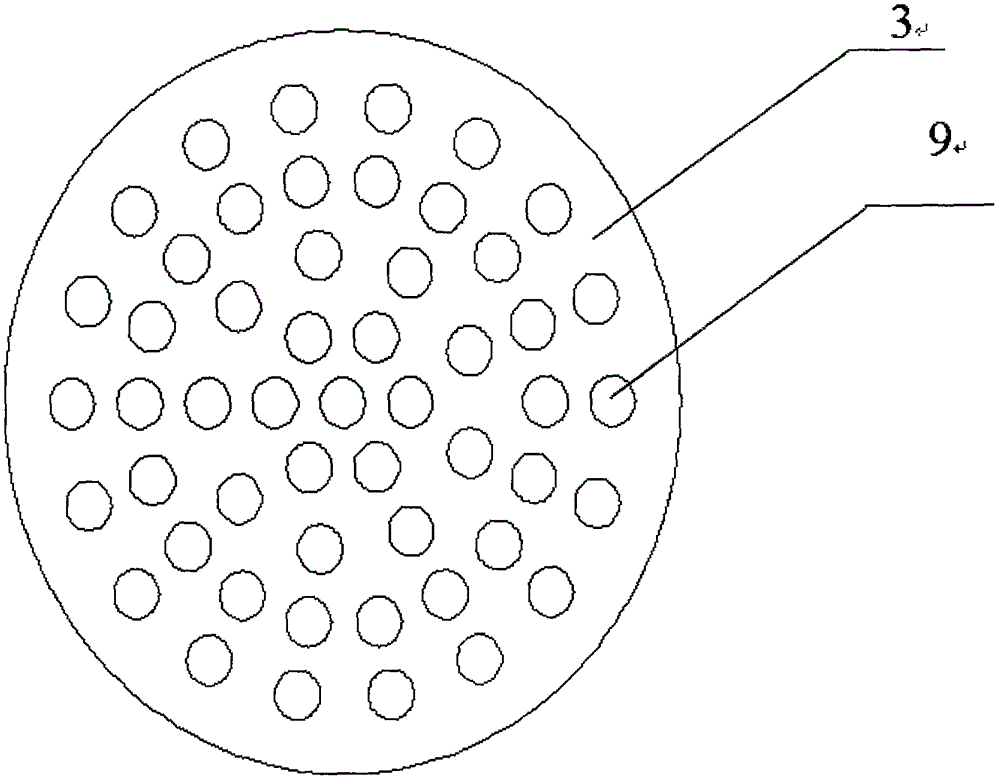

[0023] In the rectifying tower of φ 300mm, sassafras crude oil enters primary distribution plate 2 through feed pipe 1, and the aperture of primary distribution hole 8 on described primary distribution plate 2 is 20mm, and number is 17; Then enter the secondary distribution plate 3, the aperture of the secondary distribution hole 9 on the secondary distribution plate 3 is 10mm, and the number is 52; finally enter the tertiary distribution plate 4, the tertiary distribution plate 4 on the The diameter of the secondary distribution holes 10 is 5 mm, and the number is 141.

[0024] Through the multi-stage distributor of the present embodiment, the uniform distribution of the liquid can be realized, no dead space is left, and the pressure drop is also small, and the crude oil of sassafras oil with a content of 90% can be refined to 99.5%.

Embodiment 2

[0026] This embodiment is the same as Embodiment 1, on the basis of Embodiment 1: the aperture of the primary distribution hole 8 on the described primary distribution plate 2 is 25 mm, and the number is 15; The secondary distribution holes 9 have an aperture diameter of 12 mm, and the number is 48; the secondary distribution holes 10 on the tertiary distribution plate 4 have an aperture diameter of 6 mm, and the number is 128.

[0027] Through the multistage distributor of the present embodiment, the crude oil of sassafras oil with a content of 90% can be refined to 99.2%.

Embodiment 3

[0029] This embodiment is the same as Embodiment 1, on the basis of Embodiment 1: the aperture of the primary distribution hole 8 on the described primary distribution plate 2 is 18 mm, and the number is 19; The secondary distribution holes 9 have an aperture diameter of 8 mm, and the number is 60; the secondary distribution holes 10 on the tertiary distribution plate 4 have an aperture diameter of 4 mm, and the number is 166.

[0030] Through the multi-stage distributor of the present embodiment, the crude oil of sassafras oil with a content of 90% can be refined to 99.3%.

[0031] The distributor of the present invention is a gravity-type liquid distributor, which distributes the liquid by gravity. In order to make the liquid evenly distributed and consider the economy of manufacture, the present invention adopts a primary distribution plate 2 and a secondary distribution plate 3. The third-level distribution plate 4 carries out three-level distribution. The liquid first ent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com