Spark eliminator for dust collection pipelines

A technology of spark elimination and piping, applied in the direction of dispersed particle separation, chemical instruments and methods, separation methods, etc., can solve the problems of high manufacturing cost, high steel consumption, increased user investment cost, etc., and achieve the elimination of impact and burn damage , reduce operating costs and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings.

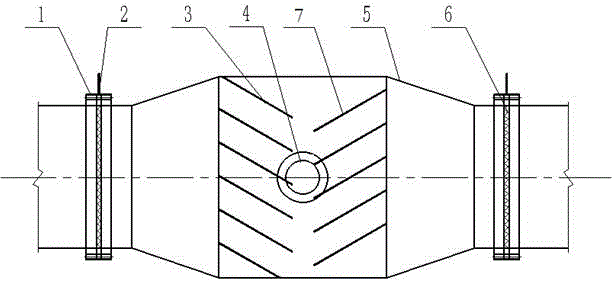

[0017] Such as figure 1 Shown is a dust removal pipeline spark elimination device, which includes a variable diameter tube 5 installed in the middle of two sections of dust removal pipelines through flanges 1 at both ends. A fire arresting net 2 is installed on one side of the reducing pipe 5, and two sets of spark arresting plates 3 are installed in the inner cavity of the reducing tube 5, and each set of spark arresting plates 3 is composed of several plates 7 parallel to each other, and the plates 7 The angle with the horizontal plane is 25-45°. The bottom wall of the reducing pipe 5 is provided with an ash discharge port 4 .

[0018] Asbestos rubber gasket 6 is installed at the joint of flange 1 .

[0019] The size of the holes on the fire arresting net 2 and the thickness of the material woven into the fire arresting net 2 are designed according to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com