Quantity-controllable batch feeder

A feeder and feeding device technology, which is applied to feed, mixer, mixer accessories, etc., can solve the problems of low efficiency, less theoretical research, unevenness, etc., to prevent material overhead and uneven distribution, and control the feeding amount. Feeding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

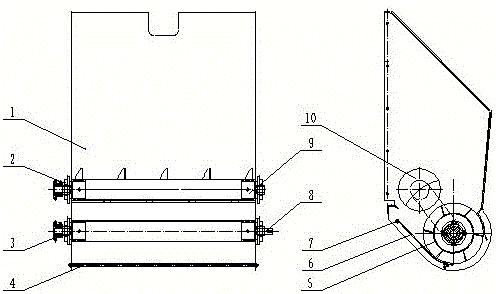

[0012] The present invention will be described in further detail below in conjunction with the embodiments given by the accompanying drawings.

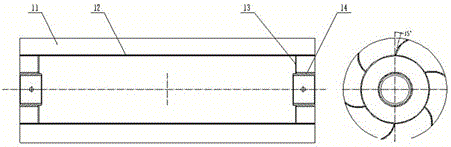

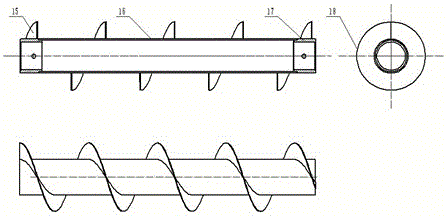

[0013] refer to figure 1 The invention discloses a controllable amount feeding device suitable for being installed on a TMR feed mixer, belonging to the technical field of agricultural machinery. Material door upper shield 1, bearing with seat 2, gear 3, hinge pin (1) 4, discharge mechanism 5, discharge tongue 6, hinge pin (2) 7, long shaft head 8, short shaft head 9, even The material auger 10 is characterized in that: the upper shield 1 of the material door is fixedly connected to the material door of the TMR feed mixer, and the even material auger 10 is connected and installed with the bearing 2 through a long shaft head 8 and a short shaft head 9 At the discharge port, the upper end of the discharge tongue 6 is hinged to the upper shield side plate of the material door through the hinge (2) 7, and the lower end of the discharge t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com