A production process and special equipment for a reinforced pull ring

A special equipment and production process technology, which is applied in the field of production equipment for pull rings, can solve problems such as tearing, lower product performance, and pull ring bending, so as to avoid bending or tearing, good processing accuracy, and high production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

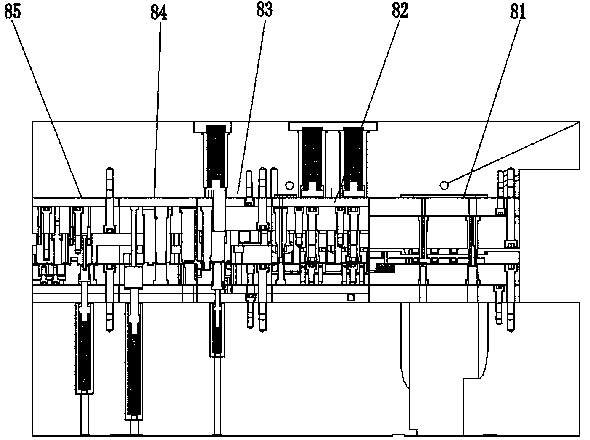

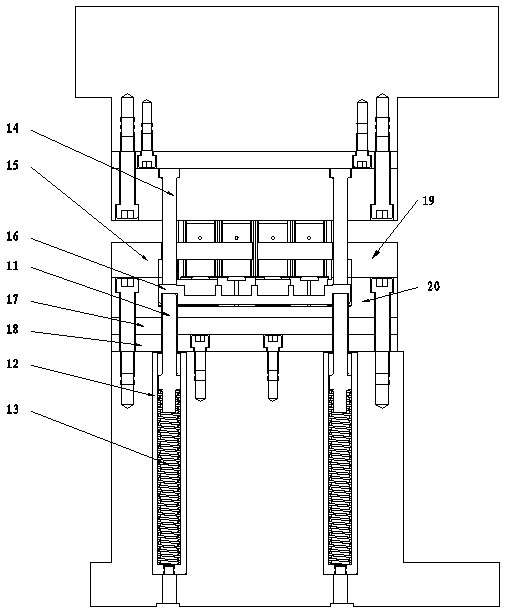

[0030] Such as figure 1 As shown, the production process of the reinforced pull ring provided by the present invention, the pull ring material belt is accurately fed through the step wheel, including punching, outer contour punching, rivet hole shaping, pre-crimping, and riveting plane forming , 90-degree curling, final curling and final strengthening of shaping steps, each step consists of a punching station 81, a large trimming station 82, a pre-curling station 83, and a 90-degree curling station.

[0031] 84 and the final crimping and shaping strengthening station 85 are carried out respectively, and the specific implementation process of the above-mentioned pull ring production process is then:

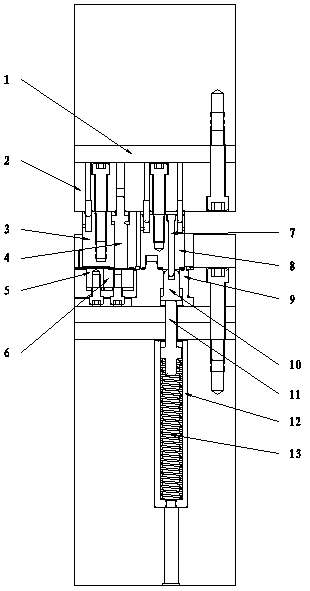

[0032] a, punching, punching ring finger holes 91, U-shaped openings 95 and rivet holes 92, are carried out by several levels of punching dies in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com