Ironclad riveting machine

An iron shell and riveting technology, applied in metal processing equipment, feeding devices, positioning devices, etc., can solve the problems of low production efficiency, unguaranteed quality, and mass production, so as to improve processing efficiency and improve Production efficiency and machining accuracy, and the effect of improving machining applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below with reference to the drawings and embodiments.

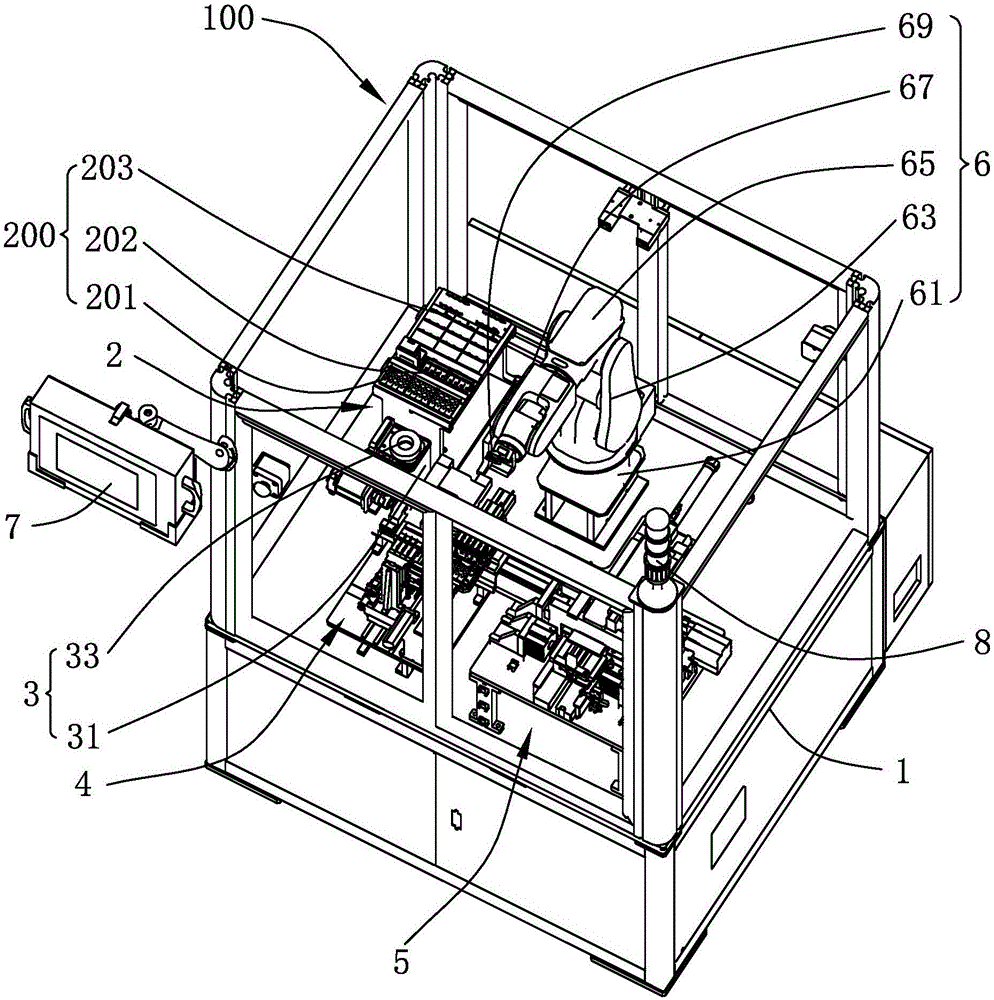

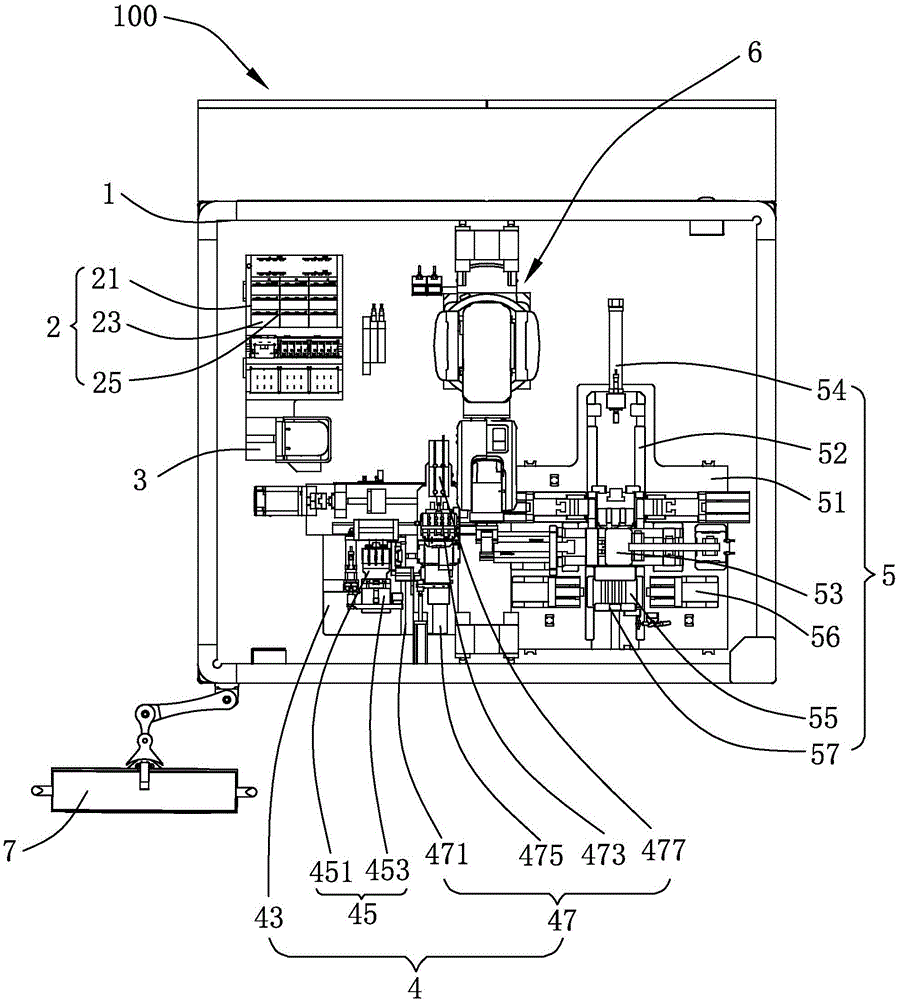

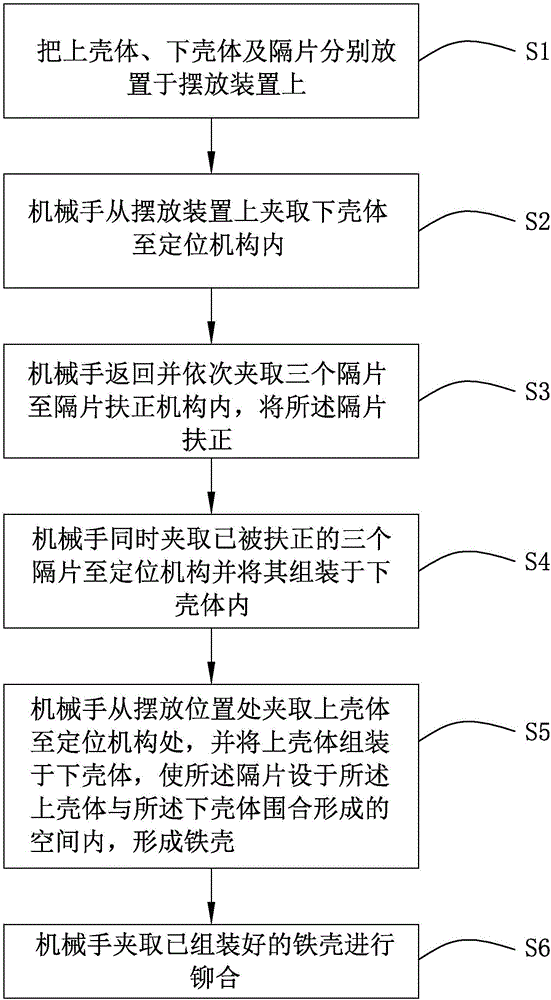

[0034] See figure 1 , Is a schematic diagram of the three-dimensional structure of the iron shell riveting machine provided by the present invention. The iron shell riveting machine 100 is used to process the upper shell 201, the lower shell 202, and the spacer 203 into an iron shell, and the spacer 203 is provided on the upper shell 201 and the lower shell 202 Inside, the iron shell riveting machine 100 includes a protective frame 1, a placement device 2, a CCD detection device 3, an assembly device 4, a riveting device 5, a manipulator 6, a control panel 7 and a signal set in the protective frame 1. Warning light 8.

[0035] The protective frame 1 is a rectangular parallelepiped steel frame, surrounded by glass to prevent the workpiece from popping out during processing to play a protective role. The control panel 7 and the signal warning light 8 are respectively fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com