Trimming method and device for punched part of cosmetic foundation cover

A technology for cosmetics and foundation, applied in turning equipment, turning equipment, metal processing equipment, etc., can solve the problems of uneven cutting surface, burr, unsuitable dimensional accuracy, high production cost, high production efficiency, feasible and effective method, Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

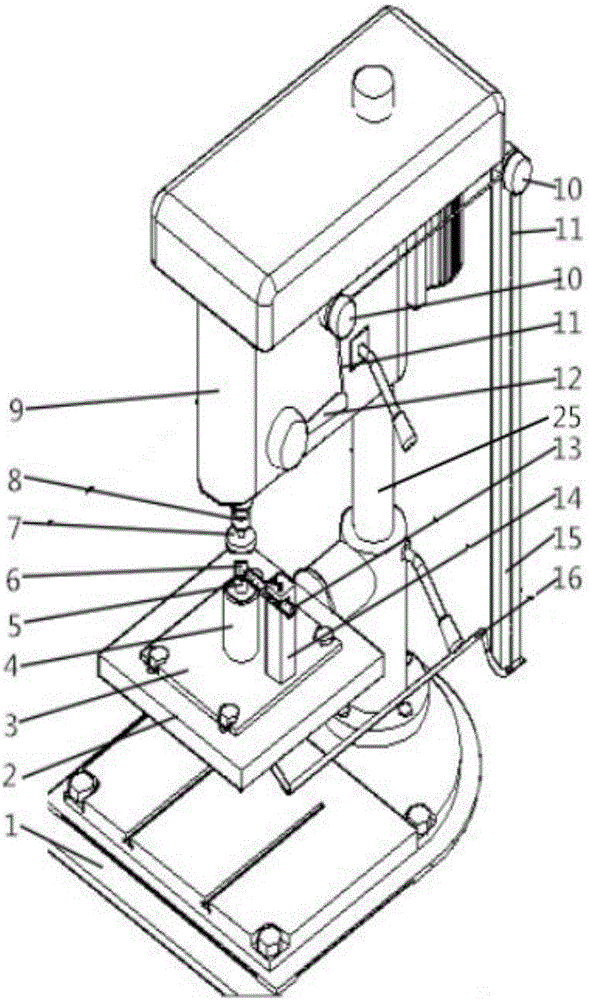

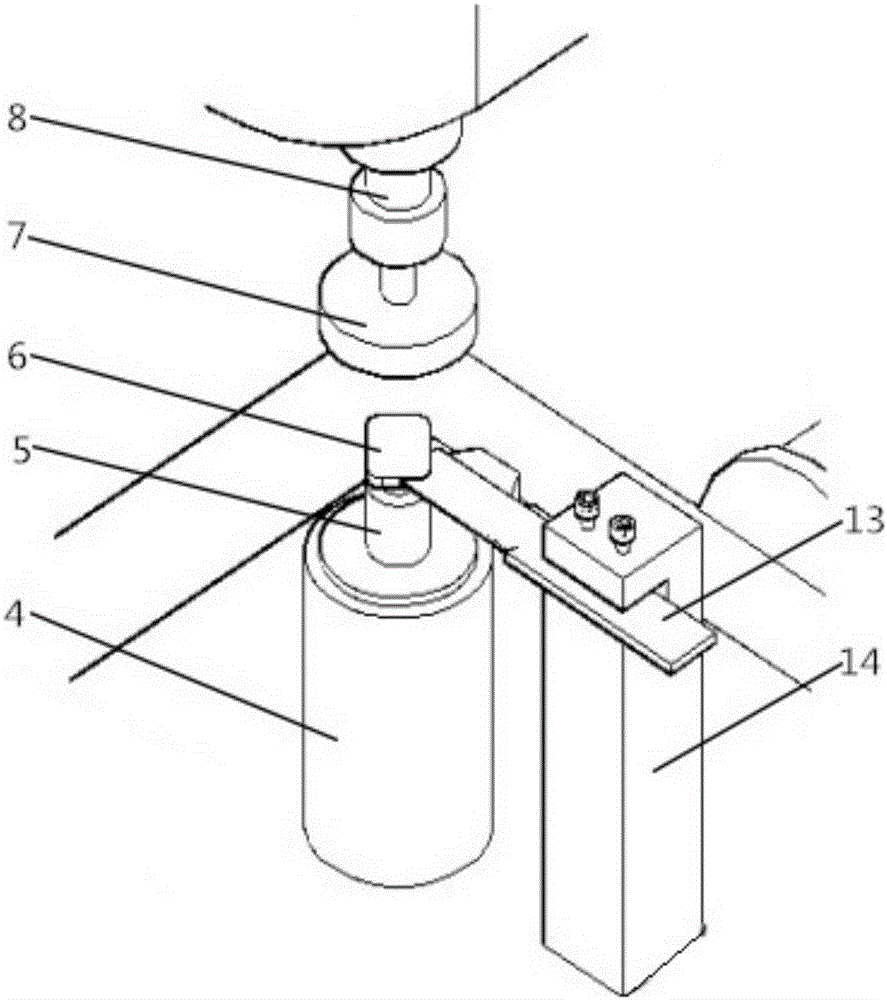

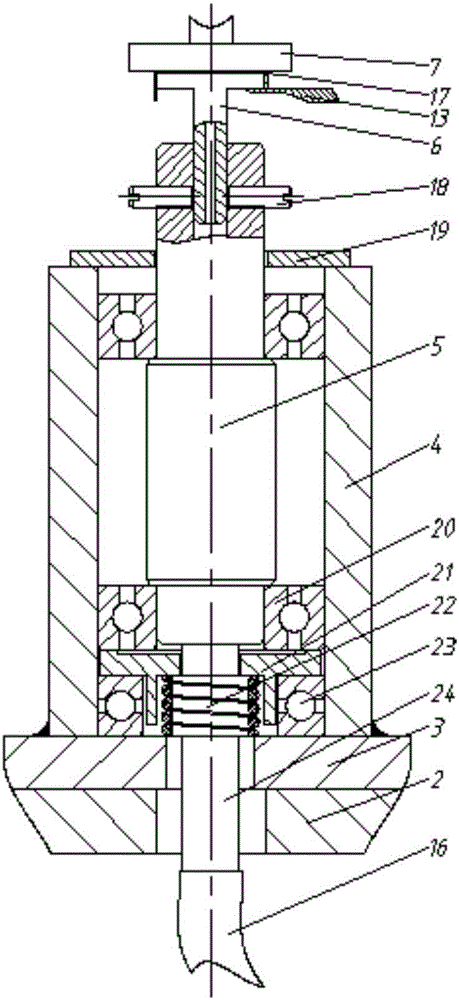

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0026] A method for trimming the blanked parts of a cosmetic foundation cover. Firstly, a thin aluminum material with a thickness of 0.5 mm to 2 mm is punched to produce a foundation cover workpiece, and then the foundation cover workpiece with burrs on the cutting surface is clamped on a machine tool, and the workpiece is used The turning tool performs secondary cutting on the cutting surface of the cosmetic foundation cover workpiece to make the cutting surface smooth and burr-free. Among them, when clamping, a mold similar in shape to the foundation cover workpiece is used, and the mold is rotatably installed on the worktable of the machine tool, and the turning tool is aligned with the burr cutting of the foundation cover workpiece according to the required height of the foundation cover workpiece after cutting position; buckle the founda...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com