Clamping device for bolt stop pipe welding

A clamping device and bolt-stop technology, which is applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of increasing the economic burden of enterprises and damage, and achieve the goal of improving surface quality, avoiding rigid contact, and reducing damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

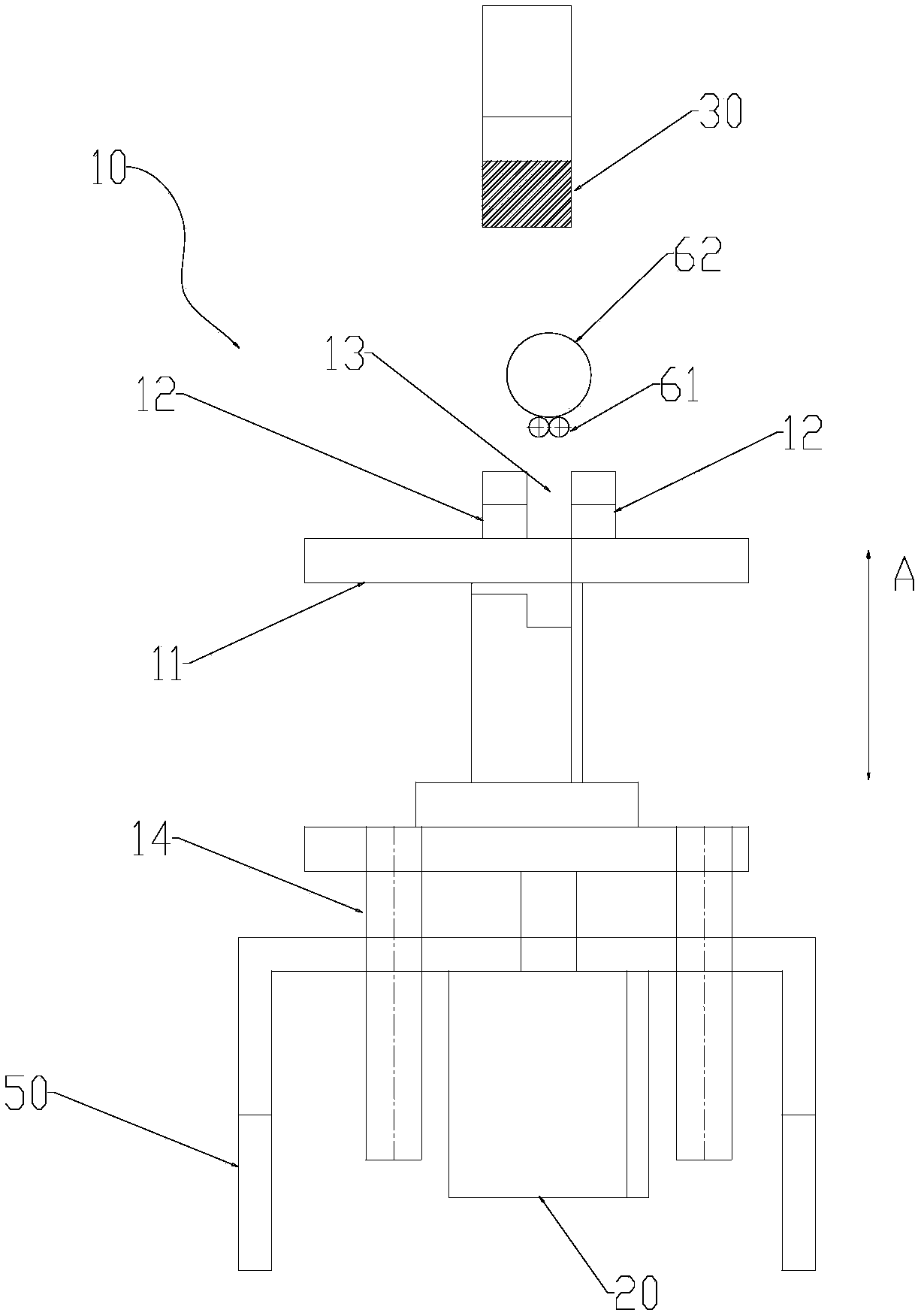

[0020] Such as figure 1 , a clamping device for bolt-stop tube material welding, including a lower mold 10, a first power component 20 for driving the lower mold 10 to move up and down, an insulating seat 30, and a second power component for driving the insulating seat 30 to move up and down; The lower mold 10 includes a base 11 and two support blocks 12 arranged on the top surface of the base 11 and extending upward; the two support blocks 12 are opposite and spaced apart; the top surface of the base 11 and the two support The block 12 encloses an accommodating cavity 13 for placing the stop bolt 61 ; the insulating seat 30 is located above the lower mold 10 and is used for pressing the pipe material 62 placed on the stop bolt 61 . Specifically, the two supporting blocks 12 are used to support the pipe material 62 placed on the stop bolt 61 to improve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com