Feeding mechanism for safe intravenous needle seat

A technology of venous needles and needle holders, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of difficult assembly of medical accessories, prolonging the assembly time of medical accessories, and inaccurate positioning of medical accessories in the front and rear directions of the rotating body. To achieve the effect of improving product quality and pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

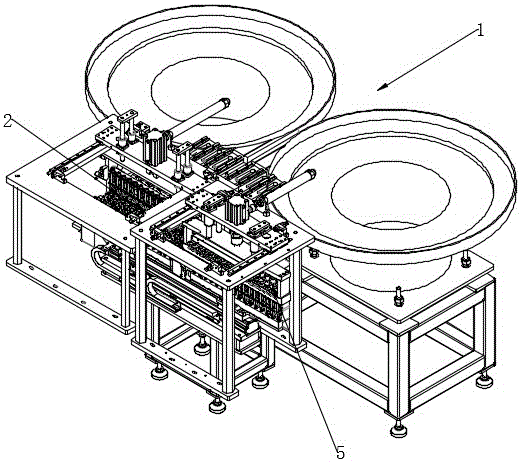

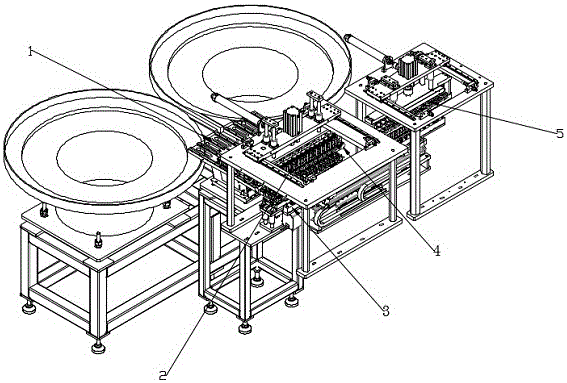

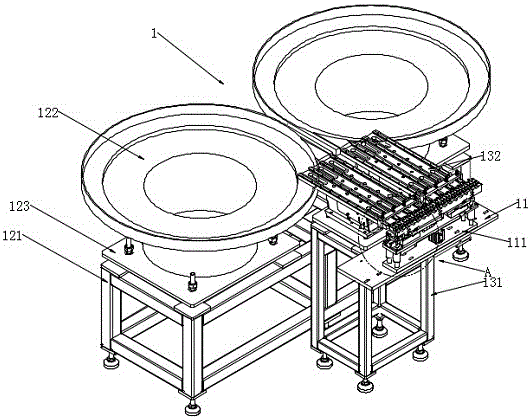

[0042] In order to make it easy to understand the technical means, creative features, goals and effects achieved by the present invention, the following examples are combined with the appended Figures 1 to 23 The feeding mechanism of the safety venous needle holder provided by the present invention is described in detail.

[0043] figure 1 It is a structural schematic diagram of an embodiment of a feeding mechanism for a safety venous needle holder; figure 2 It is a structural schematic view in another direction of an embodiment of a feeding mechanism for a safety venous needle holder; figure 1 and figure 2 As shown, the feeding mechanism provided in this embodiment is used for conveying needle holders. The feeding mechanism includes: a dislocation discharging device 1, a rotating material transfer device 2, a CCD detection device 3, and a horizontal direction adjustment device 4 and a rotary steering device 5.

[0044] In this embodiment, the position of the dislocatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com