Tension overall vibration isolation mechanism

A tensegrity and vibration isolation technology, applied in the field of vibration reduction, can solve problems such as large inertia force and resonance problems, and achieve the effect of compact structure and reduced impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following are specific embodiments of the present invention in conjunction with the accompanying drawings to further describe the technical solutions of the present invention, but the present invention is not limited to these embodiments.

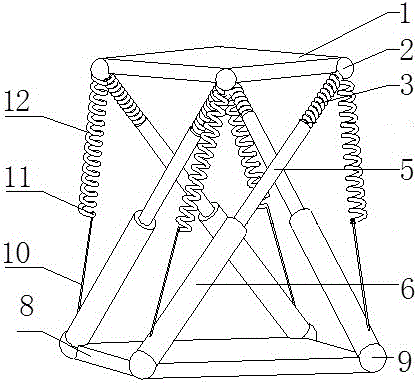

[0017] Such as figure 1 A tensioned integral vibration isolation mechanism shown includes a working platform 1, a fixed platform 8, four rigid-flexible mixed branch chains and four flexible branch chains located between the two platforms.

[0018] The rigid-flexible hybrid branch chain is composed of a hydraulic driver and a small spring 3 in series, and the upper end of the piston rod 5 of the hydraulic driver and the lower end of the small spring 3 are connected by welding. The upper end part of the spring 3 is fixedly connected with the working platform 1 through a spherical hinge-2. The lower end of the cylinder 6 of the hydraulic driver and the fixed platform 8 are fixedly connected by the two spherical hinges 9. The springs in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com