Edge trimmer for wood products

An edge trimming machine and product technology, applied in machine tools suitable for grinding workpiece edges, special forming/shaping machines, grinding frames, etc., can solve the problems of low sandpaper efficiency, large force, and high labor intensity. , to ensure the trimming effect, improve the performance, and the overall structure is simple.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, thereby making a clearer definition of the protection scope of the present invention

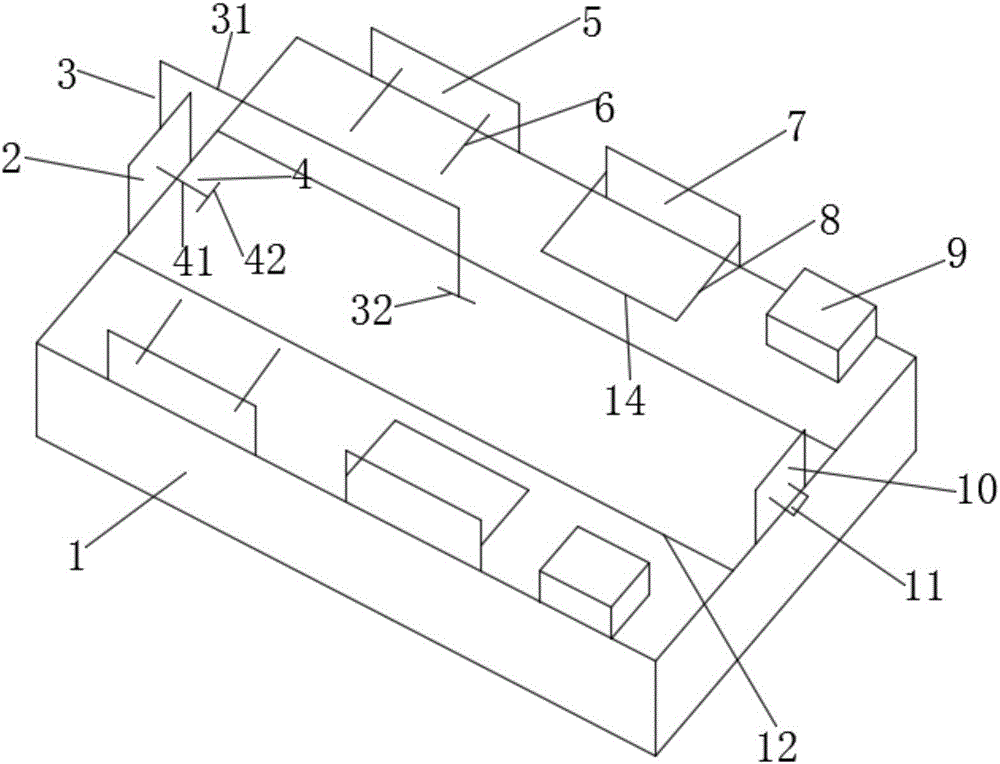

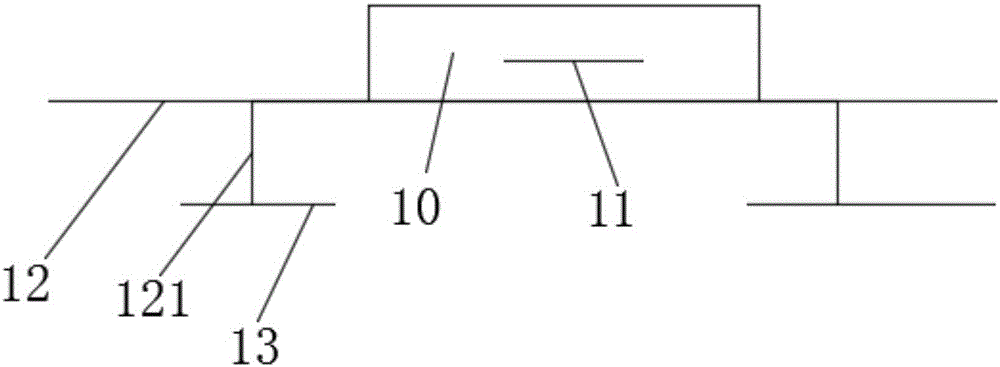

[0016] Such as Figure 1-Figure 2 As shown, a trimming machine for wood products is mainly composed of a workbench 1, a first fixing mechanism 3, a second fixing mechanism 4, an edge knife fixing block 5, an edge knife 6, a sandpaper fixing block 7, and a sandpaper Fixed frame 8, blowing pipe 9, movable baffle plate 10, fixed frame 12, guide rail 13 grades of sandpaper 14 are composed; said first fixing mechanism 3 and fixed frame 12 are provided with fixing part 2; said edge guide knife fixed block 5. Sandpaper fixing block 7-level blowing pipes 9 are symmetrically arranged side by side on both sides of the workbench 1 in sequence; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com