Anti-eccentric injection molding method and device

An eccentric and mandrel technology, applied in the field of anti-eccentric injection molding and devices, can solve the problems of uneven extrusion, bottleneck of plastic roller injection molding technology, and hinder the in-depth promotion of widely used plastic rollers, so as to improve the quality rate, prevent eccentricity, Ingenious effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

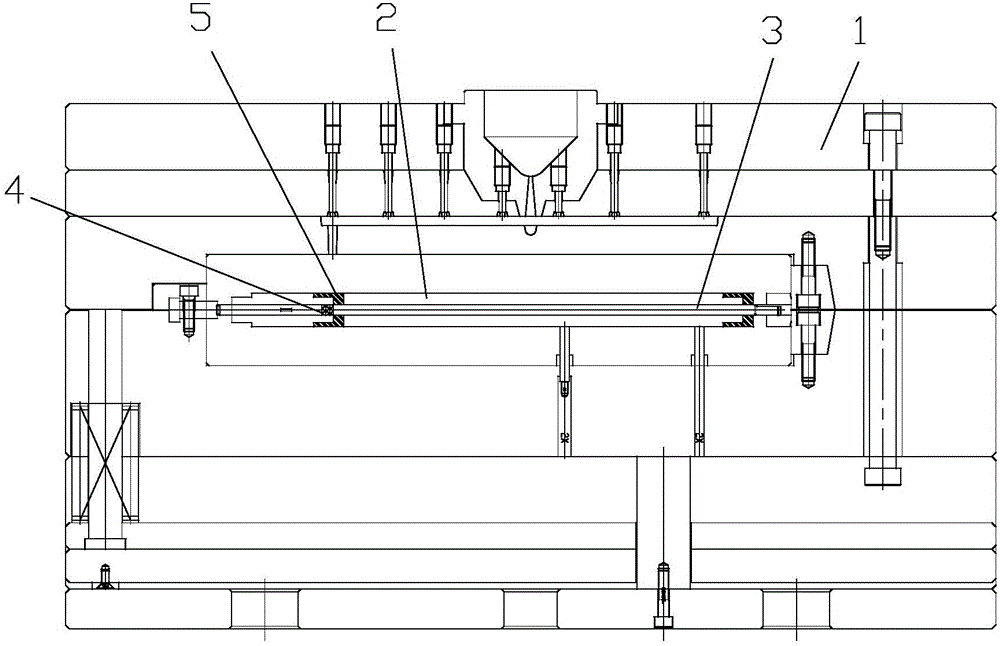

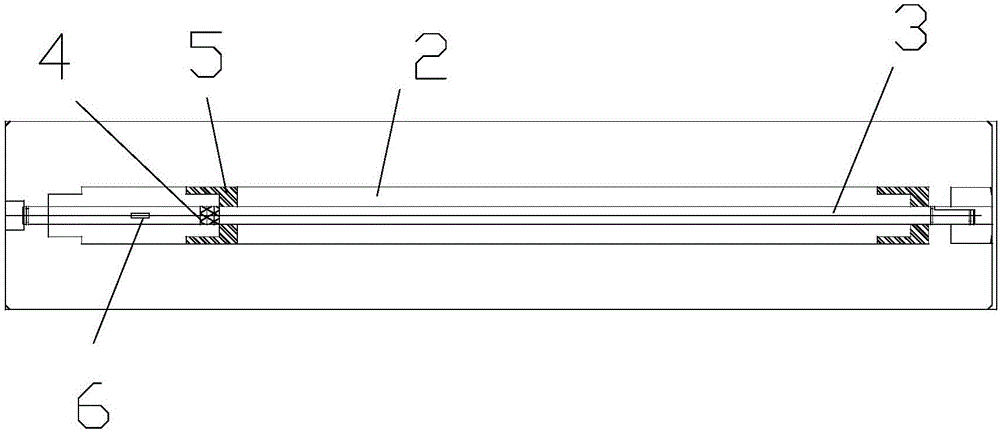

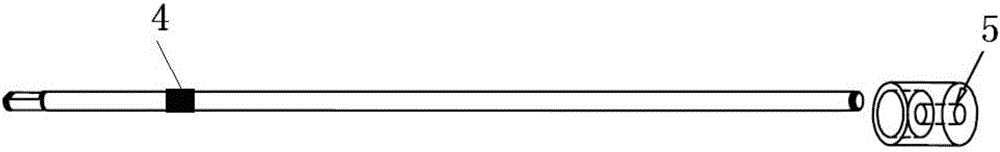

[0030] Embodiment 1: as Figure 1-3 , as shown, an anti-eccentric injection molding device, including a sprue sleeve 2 arranged on the mold base 1 and a mandrel 3 arranged in the sprue sleeve; one end of the sprue sleeve communicates with the injection gate; on the mandrel The sleeve is equipped with a sliding part 5; the outer side wall of the sliding part is adapted to the inner side wall of the sprue bushing. The injection gate is also called the nozzle.

[0031] The first end of the mandrel is provided with a limiting part 4, and the limiting part is located between the injection gate and the sliding part.

[0032] The limiting part is a stepped portion or a section of a knurled mandrel.

[0033] The sprue sleeve is a cylindrical part, and the sliding part is a cylindrical part with a shaft hole.

[0034] The inner mold of the mold base is provided with an escape cavity for accommodating the sliding part, and the escape cavity is located at the end of the mandrel away f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com