Preparation method of current collector for lithium battery and composite current collector

A technology for current collectors and lithium batteries, applied in the field of composite current collectors, can solve problems such as unsatisfactory coating effect and inability to improve thermal control, and achieve the effects of increasing thickness, improving heat resistance, and preventing burning or deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

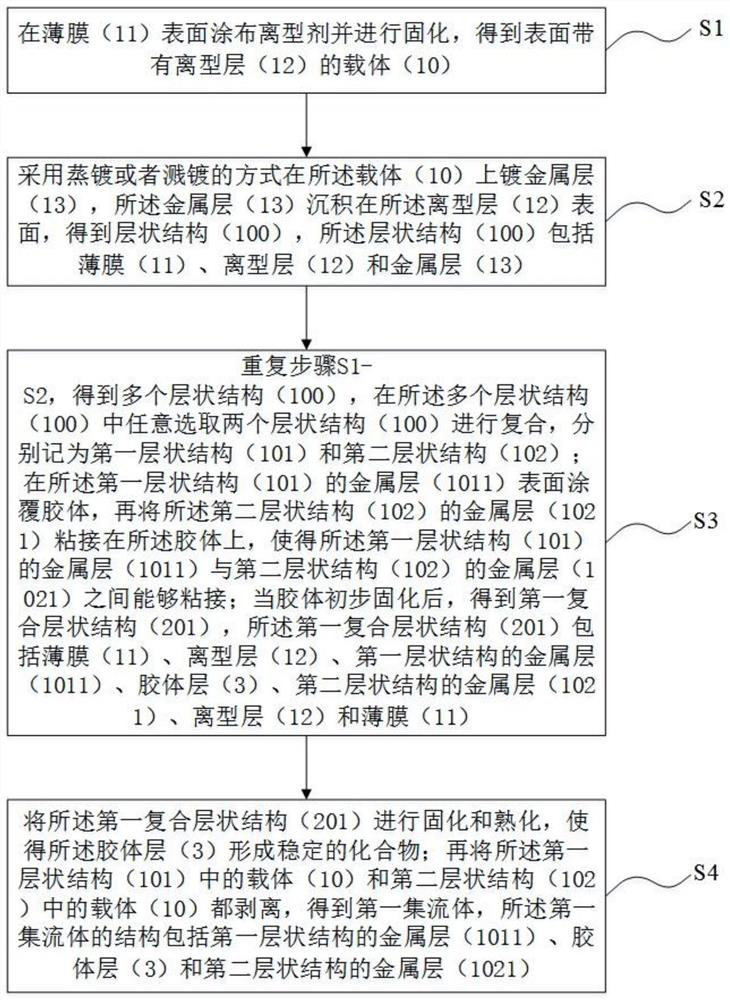

[0035] like figure 1 Shown, a kind of preparation method of current collector for lithium battery comprises the following steps:

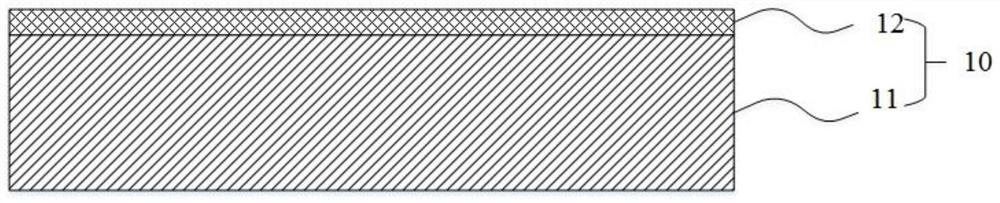

[0036] S1: Coating and curing a release agent on the surface of the film 11 to obtain a carrier 10 with a release layer 12 on the surface.

[0037] It should be noted that the film 11 may be made of paper, plastic or metal. Depending on the manufacturing process, a suitable film 11 material can be selected. Coating a release agent on the surface of the film 11 makes it easier for the carrier 10 to be peeled off from the metal layer 13 . When performing evaporation or sputtering, it is better to select the thin film 11 with heat resistance. For example, the thin film 11 made of metal can achieve heat resistance above 500°C.

[0038] S2: The metal layer 13 is plated on the carrier 10 by evaporation or sputtering, and the metal layer 13 is deposited on the surface of the release layer 12 to obtain a layered structure 100. The layered structure 100...

Embodiment 1

[0051] A release agent was coated on the surface of a PET film with a thickness of 50 microns and cured to obtain a carrier, and the thickness of the release layer on the carrier was 10 nm.

[0052] A winding-type evaporative vacuum coating machine is used to evaporate copper on the surface of the release layer on the PET film, and the copper layer is deposited on the surface of the release layer to obtain a layered structure. The layered structure includes a PET film, a release layer and a copper layer, wherein the thickness of the copper layer is 0.7 microns.

[0053] By repeating the above steps, multiple layered structures can be obtained, and two layered structures are arbitrarily selected from among the multiple layered structures for compounding. The two layered structures are respectively recorded as the first layered structure and the second layered structure. Colloid is coated on the surface of the copper layer of the first layered structure by using winding composit...

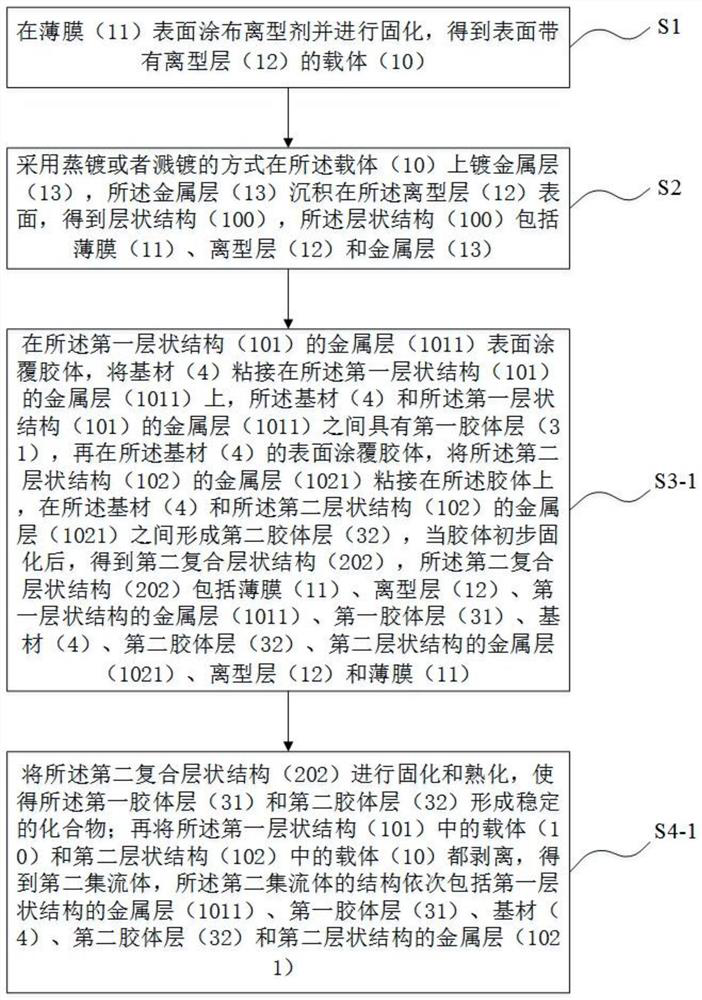

Embodiment 2

[0056] A release agent was coated on the surface of a PET film with a thickness of 50 microns and cured to obtain a carrier, and the thickness of the release layer on the carrier was 10 nm.

[0057] A winding-type evaporative vacuum coating machine is used to evaporate copper on the surface of the release layer on the PET film, and the copper layer is deposited on the surface of the release layer to obtain a layered structure. The layered structure includes PET film, release layer and copper layer. Wherein, the thickness of the copper layer is 0.7 microns.

[0058] The above steps are repeated to obtain multiple layered structures, and two layered structures are arbitrarily selected from the multiple layered structures for compounding, and the two layered structures are respectively recorded as the first layered structure and the second layered structure. Use winding compound equipment, use 3 micron thick PET film as the substrate, coat the colloid on the surface of the coppe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com