Improved press structure of paper laminating machine

A laminating machine and frame technology, applied in the field of improved laminating machine press structure, can solve the problems of long debugging time and easily damaged belts, and achieve the effects of simple structure, reduced adjustment accuracy and remarkable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

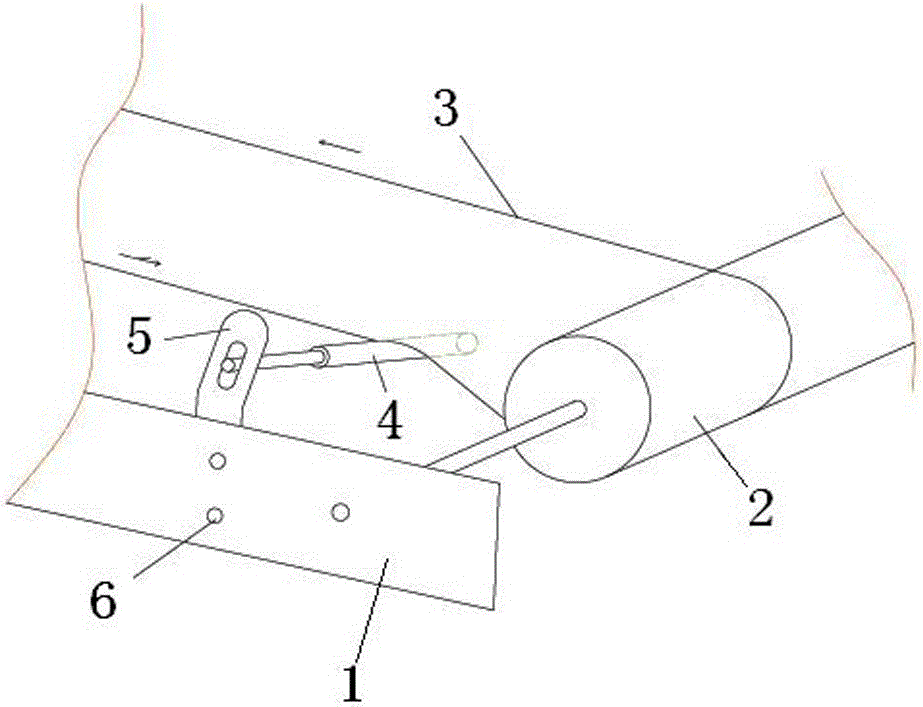

[0010] figure 1 An embodiment of an improved structure of the laminating machine press of the present invention is shown, including a belt roller 2 installed on the laminating machine frame 1 and a conveying belt 3 on the surface of the belt roller. A belt adjustment roller shaft 4 is installed below, one end of a corner adjustment block 5 is fixed on one side of the laminator frame 1 by a fixing screw 6, and the other end is connected with a belt adjustment roller shaft 4, which is adjusted at the rotation angle. The rotation of the block 5 drives the conveyor belt 3 to move left or right, the angle adjustment block 5 is bent at an angle of 30 degrees, an adjustment groove is provided in the middle of the angle adjustment block 5, and one end of the belt adjustment roller shaft 4 is inserted in the In the adjustment groove, the belt adjustment roller shaft 4 is adjusted up and down on the 30° angle adjustment block 5 to control the left or right direction of the belt to preve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com