Middle-and-long distance guide wheel tire pattern

A tire pattern and guide wheel technology, applied in the field of tire pattern, can solve the problems of reducing the service life of tires, prone to stone trapping, and increasing rolling resistance, etc., to achieve reduced tire wear, good stone removal performance, and good wear resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

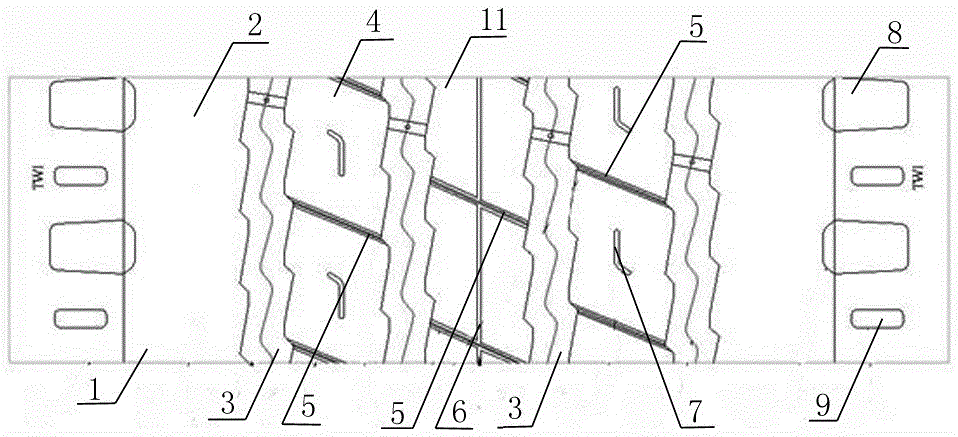

[0024] as attached Figure 1-7 As shown, a medium and long-distance guide wheel tire pattern includes a tread pattern 1, and the tread pattern 1 is composed of a first pattern block 2, a second pattern block 4, a third pattern block 11 and a first pattern block continuous in the circumferential direction. The first pattern groove 3 between the pattern block 2 and the second pattern block 4 and between the second pattern block 4 and the third pattern block 11 is composed of the first pattern groove 3 on the second pattern block 4 and the third pattern block 11. A sipe 5, a second sipe 6 is provided on the third pattern block 11, a fourth sipe 8 and a fifth sipe 9 are provided on the first pattern block 2;

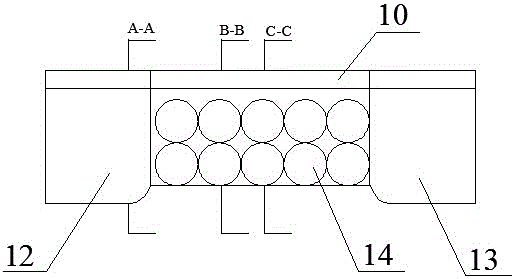

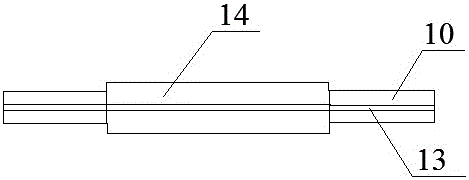

[0025] Steel sheet 12 is inlaid in the first sipe 5, and steel sheet 12 comprises common steel sheet part 13, three-dimensional steel sheet part 14 and the connecting steel sheet part 10 that connects common steel sheet part 13 and three-dimensional steel sheet part 14, thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com