Control method of weighing re-inspection scale

A control method and technology of a control system are applied in the control field of weighing and repeating inspection, which can solve the problem of low precision and achieve the effects of improving production efficiency and improving working conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

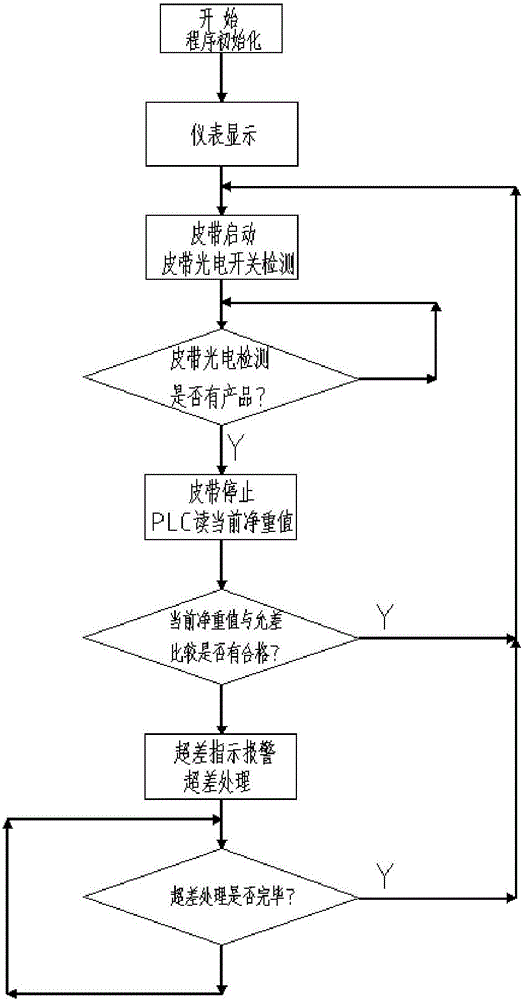

[0017] The present invention will be further described below in conjunction with specific drawings.

[0018] The control method of the weighing and rechecking scale described in the present invention controls the weight of the packaged goods within the qualified range, and the device for realizing the weighing and rechecking scale control method includes: a PLC control system, a weighing instrument and a load cell; The sensor is installed under the re-inspection belt conveyor, holding up the entire re-inspection belt conveyor as a weighing platform, the PLC control system is installed in the re-inspection scale control cabinet, and the weighing instrument is installed on the cabinet door of the re-inspection scale control cabinet , which is convenient for the operator to observe the actual weight of the item. The PLC control system communicates with the weighing instrument through the serial port MODBUS 485, and reads the target value, tolerance value, and net weight value of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com