Speed reducer storing device

A storage device and reducer technology, which is applied in the directions of packaging food, assembly machines, assembly vehicles, etc., can solve problems such as aging, affecting performance, corrosion of reducer, etc., to achieve convenient handling and batch transfer, and avoid direct contact with air , the effect of prolonging the storage time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

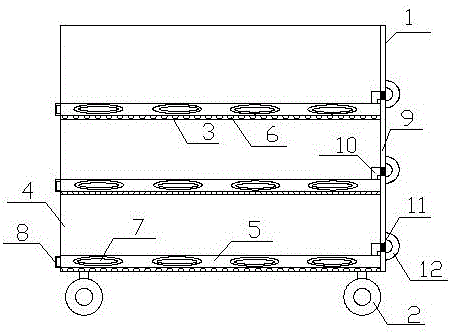

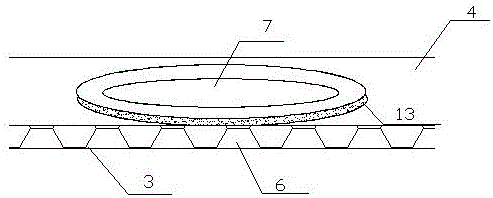

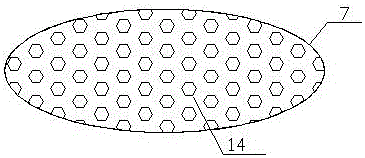

[0017] Such as figure 1 It is a structural schematic diagram of the present invention, figure 2 is a partially enlarged schematic diagram of the base plate, image 3 is the schematic diagram of the bottom of the base plate, Figure 4 It is the right view of the box body, a storage device for a reducer, including a box body 1, a pulley 2 is provided at the bottom of the box body 1, and several fixing plates 3 are arranged inside the box body 1, and the fixing plates 3 are horizontally fixed on the Inside the box body 1, and the box body 1 is divided into several compartments 4, a base layer 5 is arranged above the fixed plate 3, a roller bar 6 is arranged on the surface of the fixed plate 3, the base layer 5 is placed on the roller bar 6, and the base layer 5 is provided with a circular hole 15 on the surface, and a base plate 7 is placed in the circular hole 15. One end of the base layer 5 is provided with a pull ring 8, and the pull ring 8 is arranged on the outside of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com