Device for preventing slippage of belt of belt conveyor

A belt conveyor and belt slipping technology, applied in the direction of conveyor control devices, conveyor objects, transportation and packaging, etc., can solve problems such as misunderstanding and failure to provide slipping protection, and achieve the effect of perfect protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

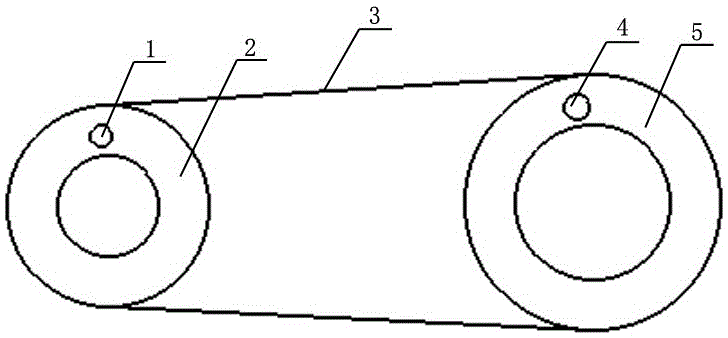

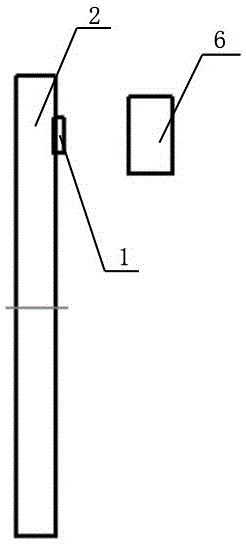

[0011] The structure of the invention is to solve the problem that the drive wheel driven by the frequency conversion motor slips during the belt transmission process and cannot be measured by existing technical means. Since the speed of the drive wheel often changes, slipping often occurs when the speed changes. In the first stage, due to the elasticity of the belt, there will be a certain delay period from the transmission of power from the driving wheel to the driven wheel, making the existing detection equipment unable to meet the requirements for detecting slippage.

[0012] Such as figure 1 with figure 2 As shown, the present invention installs patches and proximity switches on the driving wheel and the driven wheel. During the rotation process of the driving wheel and the driven wheel, the patch will periodically approach the proximity switch, so that the proximity switch will generate a pulse. The frequency of can accurately determine the speed of the wheel. The PLC...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com