An optimal path conveying system and its raw material storage and mixing parallel production process

A conveying system and optimal path technology, applied in the optimal path conveying system and its raw material storage and mixing parallel production process, can solve the problems of increasing logistics costs and energy consumption costs, and achieve controllable transportation rhythm and reduce The effect of raw material transportation distance and logistics informatization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

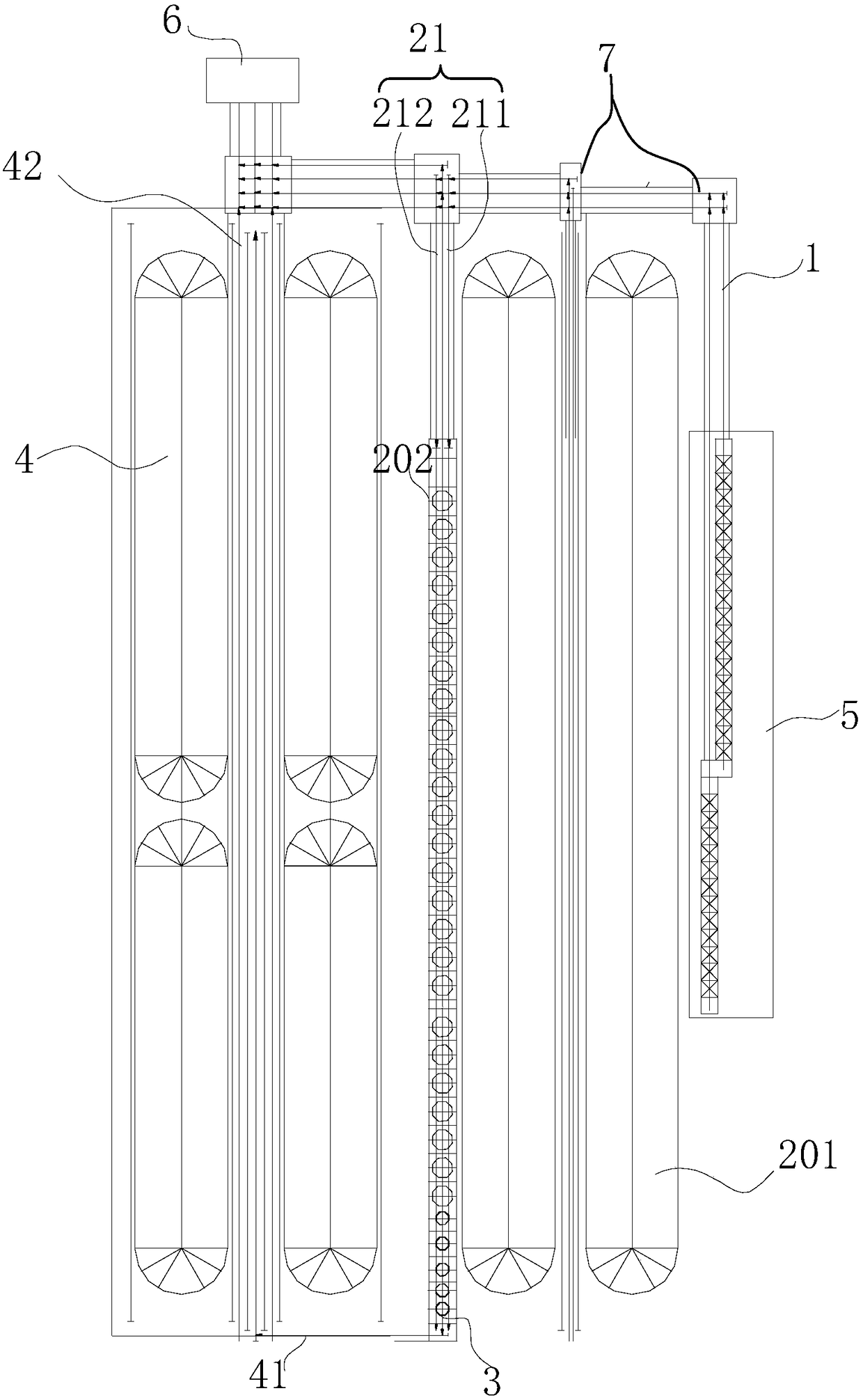

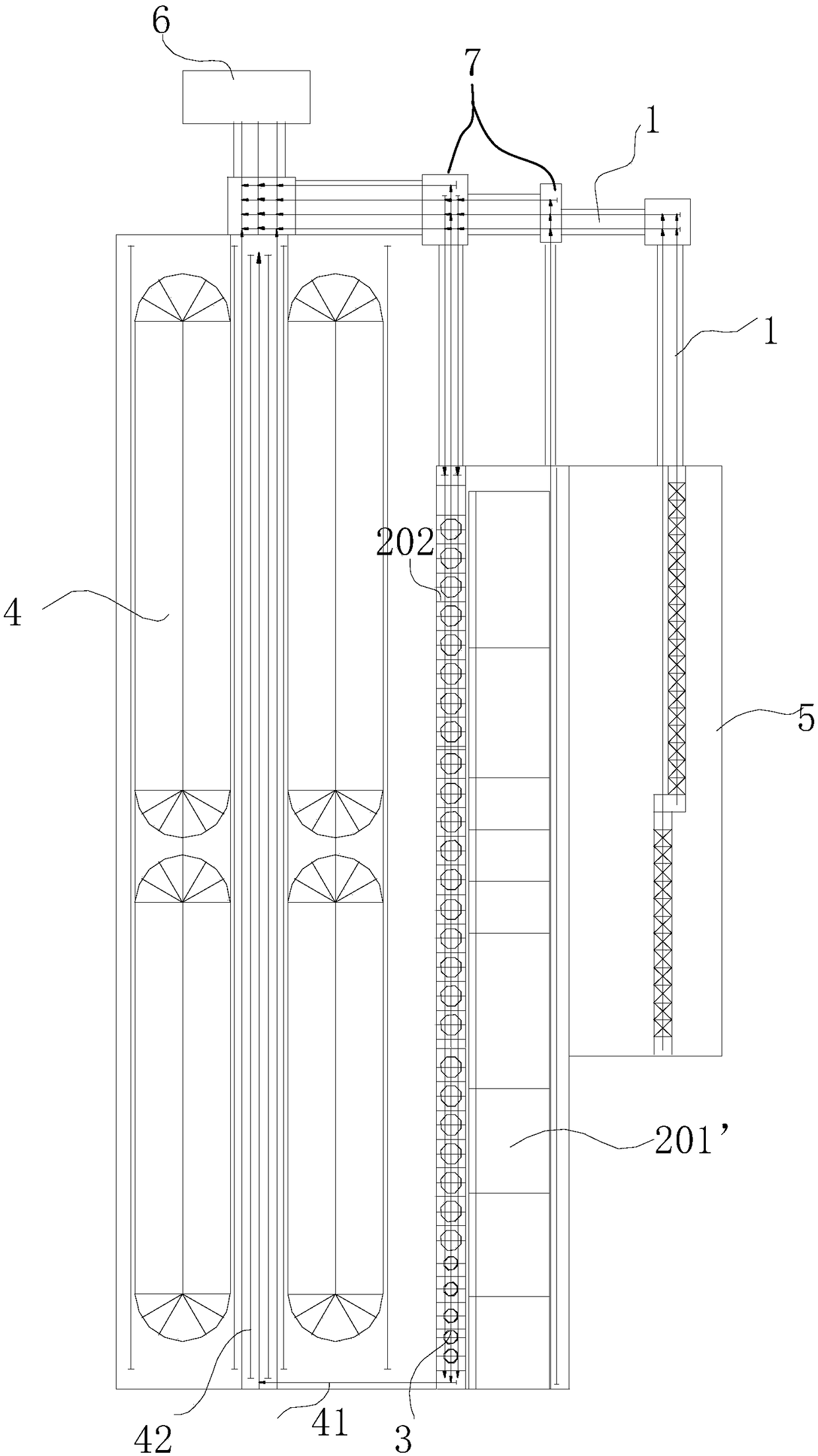

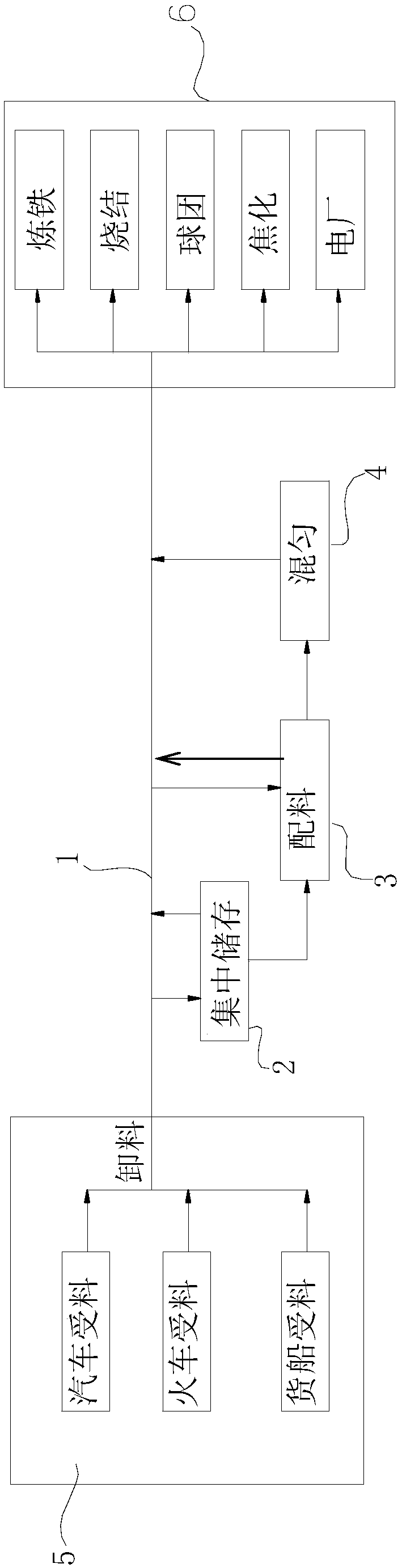

[0039] For this reason, the present invention proposes an optimal route conveying system, which is arranged between the unloading unit and the material-using unit, which includes: a conveying main line for transporting raw materials, one end of the conveying main line is located at the unloading unit place, the other end of which is connected to the material unit, and the conveying trunk line can directly transport raw materials from the unloading unit to the material unit; a storage unit for storing raw materials, and the storage unit A conveying branch line is provided between the conveying trunk lines to transmit raw materials between the conveying trunk lines and the storage unit; a batching unit for batching raw materials, which is adjacent to the storage unit, can Receive the raw materials provided by the conveying trunk line and the material storage unit, and provide them to the mixing unit or the material use unit through batching; the mixing unit for uniformly mixing t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com