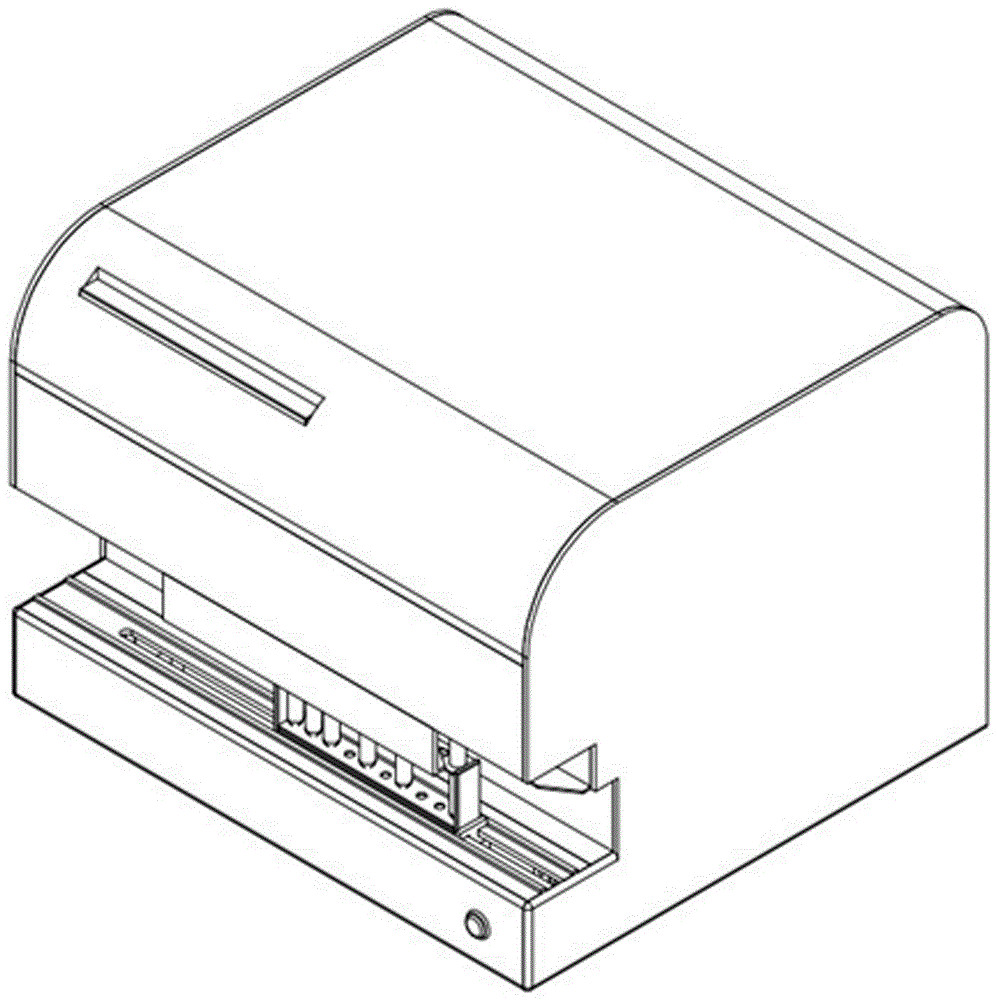

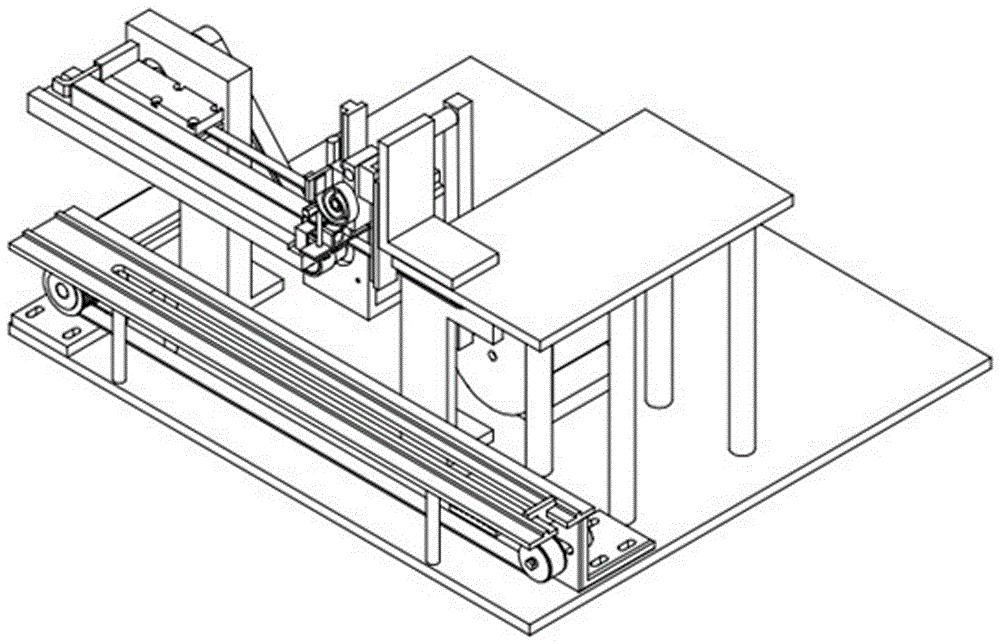

Cap covering machine of vacuum blood-collecting tube

A technology of vacuum blood collection tubes and blood collection tubes, which is applied in the direction of flanged bottle caps and non-threaded stoppers, which can solve the problems of low work efficiency of manual caps, high labor intensity of operators, and infection of operators, so as to avoid possible infection , Reduce labor intensity and reduce labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

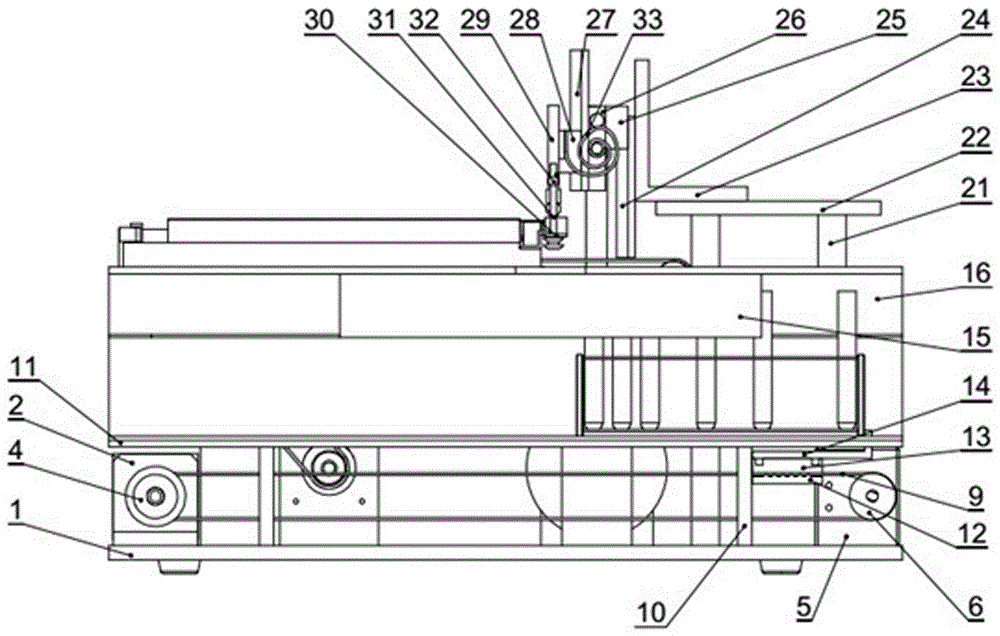

Embodiment Construction

[0033] A vacuum blood collection tube automatic capping machine, comprising a blood collection tube transmission and positioning component, a cap pressing component, a cap pusher and a cap removal tube component, the blood collection tube transmission and positioning component includes: a frame 1, a motor base 2, a motor 13, pulley 4, L-shaped driven pulley-support plate 5, driven pulley 6, driven pulley-fixing block 7, Adjust fixed block 8, timing belt one 9, test tube rack guide plate pillar 10, test tube rack guide plate 11, timing belt lower splint 12, timing belt one upper splint 13, test tube rack push block 14, blood collection tube front guide plate 15 and blood collection tube Blood vessel rear guide plate 16, wherein motor one support 2 is fixed on the frame 1, motor one 3 is fixed on the motor one support 2, belt pulley one 4 is connected with motor one 3 output shafts, driven wheel one support plate 5 The horizontal panel is fixed on the frame 1, and one end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com