Water purification system applied to pure water treatment

A water purification system and pure water technology, which is applied in the field of water treatment, can solve the problems of microelectronic technology complexity, product quality, lack of, and variety, and achieve high-quality water filtration effects and reduce water filtration costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

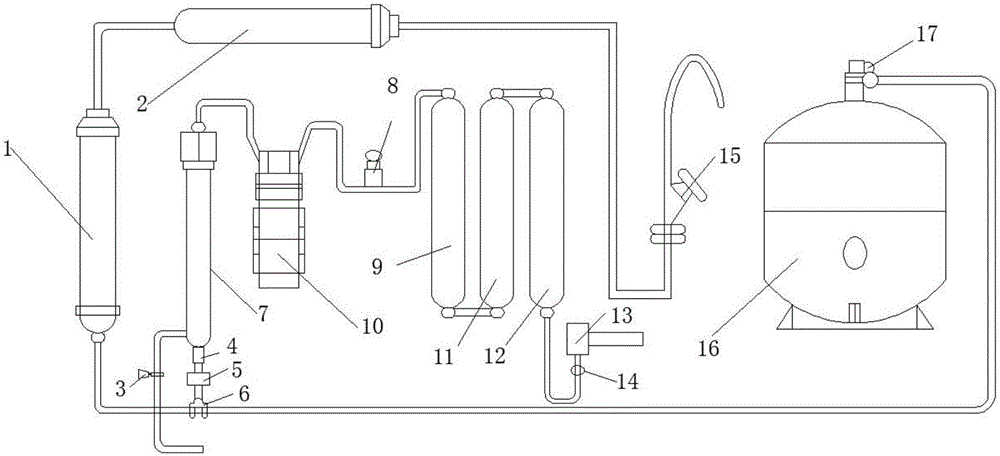

[0035] A water purification system applied to pure water treatment. The water purification system based on the multi-stage filter membrane structure design can filter and sterilize tap water to obtain pure water that can be used directly. Its scientific design structure can achieve high-quality The water filtration effect, and effectively reduce the cost of water filtration, such as figure 1 As shown, the following configuration structure is adopted in particular: water inlet equipment, first-stage filter membrane group, booster pump 10, fourth-stage filter element 7, fifth-stage filter element 1 and sixth-stage filter element 2 are provided; the water inlet equipment It is connected with the water inlet end of the first-stage filter membrane group, the water outlet end of the first-stage filter membrane group is connected to the water inlet end of the booster pump 10 through a pipeline, and the water outlet end of the booster pump 10 is connected to the inlet port of the fourt...

Embodiment 2

[0037] This embodiment is further optimized on the basis of the above-mentioned embodiments. Further, in order to better realize the present invention, when the fourth-stage filter element is sent to the fifth-stage filter element after water treatment, there will be no backflow situation, such as figure 1 As shown, the following setting method is adopted in particular: a check valve 4 and a high pressure switch 5 are sequentially arranged on the water outlet end of the fourth-stage filter element 7, and the check valve 4 is close to the clean water outlet of the fourth-stage filter element 7. Water outlet setting.

Embodiment 3

[0039] This embodiment is further optimized on the basis of any of the above-mentioned embodiments. Further, in order to better realize the present invention, it can provide sufficient working pressure for the fourth-stage filter element and the fifth-stage filter element, such as figure 1 As shown, the following arrangement is adopted in particular: a pressure barrel 16 is also included, and the pressure outlet end of the pressure barrel 16 is connected to the water outlet end of the fourth-stage filter element 7 and the fifth-stage filter element 1 through a pipeline and a tee 6 On the pipe connected to the water inlet.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com