Water purification processor based on water-quality-detector real-time water quality detection

A water quality detection and detector technology, applied in the field of water treatment, can solve the problems of many, no, and complex product quality factors of microelectronic technology, and achieve the effect of scientific design, reasonable use and high-quality water filtering effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

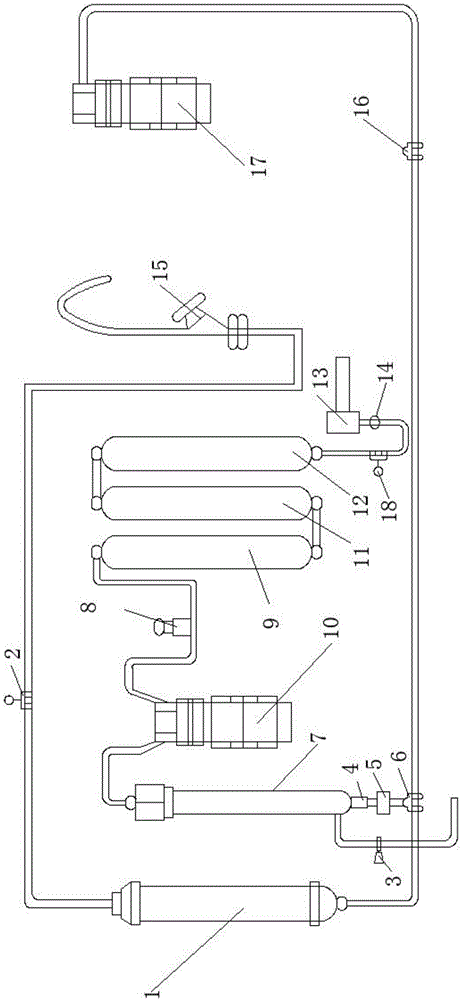

[0036] A water purification processor based on real-time water quality detection by a water quality detector, and a water purification system based on a multi-stage membrane structure design, which can filter and sterilize tap water to obtain pure water that can be used directly. Its scientific design structure, It can achieve high-quality water filtration effect and effectively reduce the cost of water filtration, such as figure 1 As shown, the following arrangement structure is adopted in particular: including water inlet equipment, first-stage filter membrane group, booster pump 10, fourth-stage filter element 7 and fifth-stage filter element 1; The water inlets of the group are connected to each other, the water outlet of the first-stage filter membrane group is connected to the water inlet of the booster pump 10 through a pipeline, and the water outlet of the booster pump 10 is connected to the water inlet of the fourth-stage filter element 7 through a pipeline, and the fo...

Embodiment 2

[0038] This embodiment is further optimized on the basis of the above-mentioned embodiments. Further, in order to better realize the present invention, when the fourth-stage filter element is sent to the fifth-stage filter element after water treatment, there will be no backflow situation, such as figure 1 As shown, the following arrangement is adopted in particular: the check valve 4 is arranged near the water outlet end of the fourth-stage filter element 7, and the high-pressure switch 5 is arranged between the check valve 4 and the tee 6.

Embodiment 3

[0040] This embodiment is further optimized on the basis of any of the above-mentioned embodiments. Further, in order to better realize the present invention, it can effectively load pressure on the fourth-stage filter element, such as figure 1 As shown, the following configuration is particularly adopted: the tee 6 is a T-shaped tee, and the high-pressure valve 5 is arranged between the vertical interface of the tee 6 and the check valve 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com