Method for preparing ferrite epitaxial film with room temperature broadband large magnetocapacitance effect

An epitaxial thin film, ferrite technology, applied in vacuum evaporation coating, coating, sputtering coating and other directions, can solve the problem that the large magnetic capacitance effect can only appear in the low frequency range, and achieve easy operation and simple preparation method. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

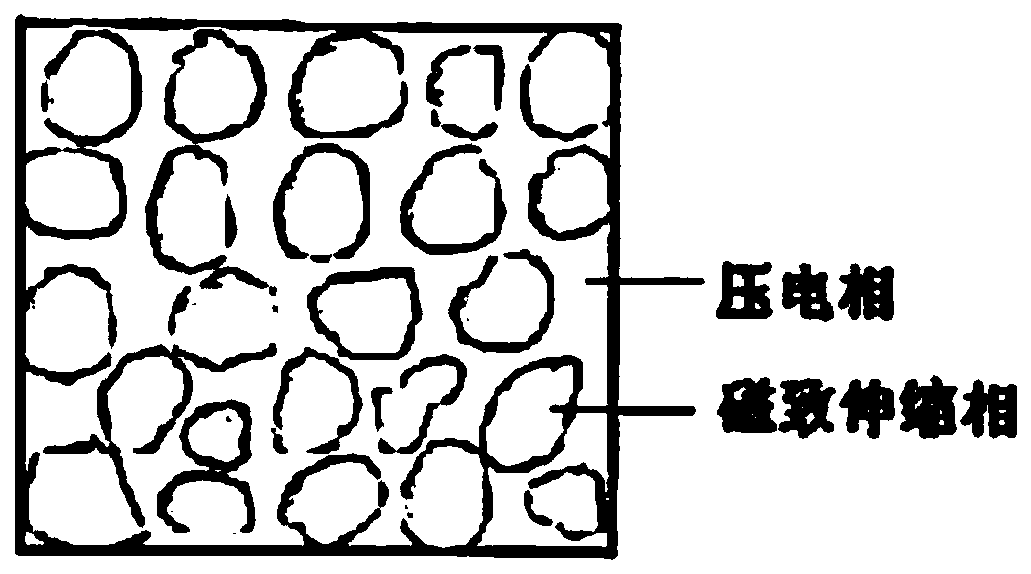

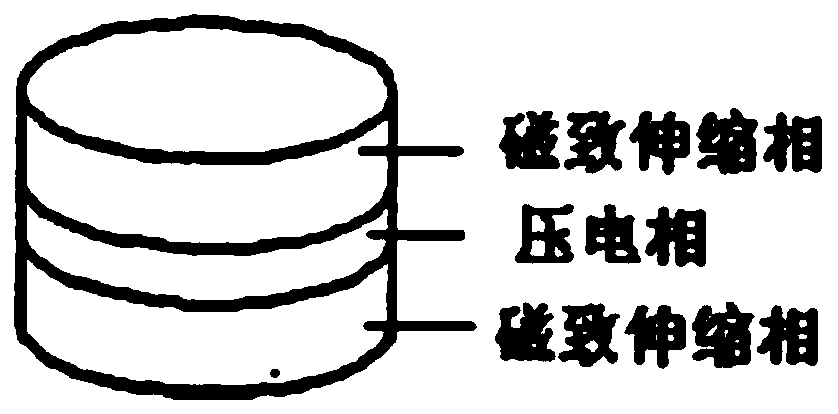

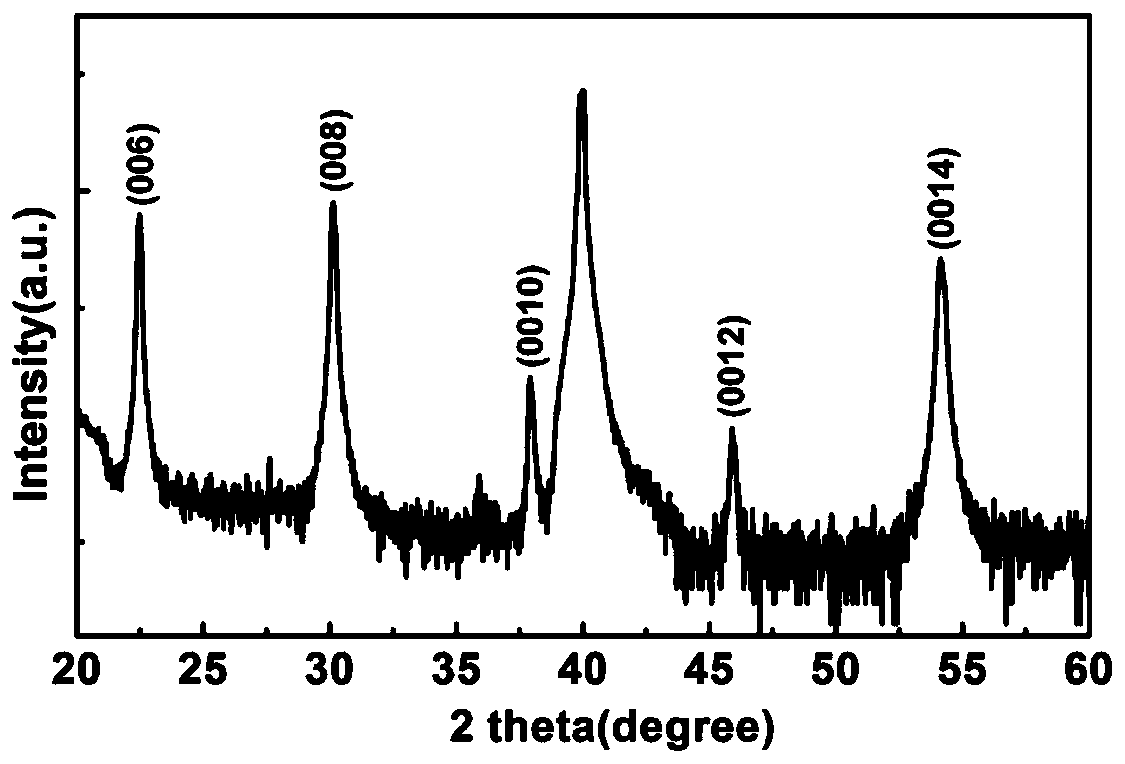

[0042] The ferrite epitaxial film material in the present invention has molecular formula: AFe 12-x m x o 19, wherein A is at least one of Ba element or Sr element, M is at least one of Sc element, Mg element or Cr element, and x is the content of M: 0<x≤4.

[0043] The concrete preparation method of ferrite epitaxial film of the present invention is as follows:

[0044] (1) Preparation with AFe 12-x m x o 19 Indicates the composition of ferrite, wherein A is at least one of Ba element or Sr element, M is at least one of Sc element, Mg element or Cr element, and x is the content of M: 0<x≤4;

[0045] (2) The ferrite epitaxial film was prepared by pulsed laser deposi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com