Automatic water supplementing device for cocoon supplier

An automatic water replenishment and cocoon feeding machine technology, which is applied in mechanical processing, silk fiber production, textiles and paper making, etc., can solve the problems of water supply for cocoon feeding machines, high manufacturing and maintenance costs, complex structure, etc., and achieve accurate water replenishment and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make those skilled in the art better understand the technical scheme of the present invention, the present invention will be further described below:

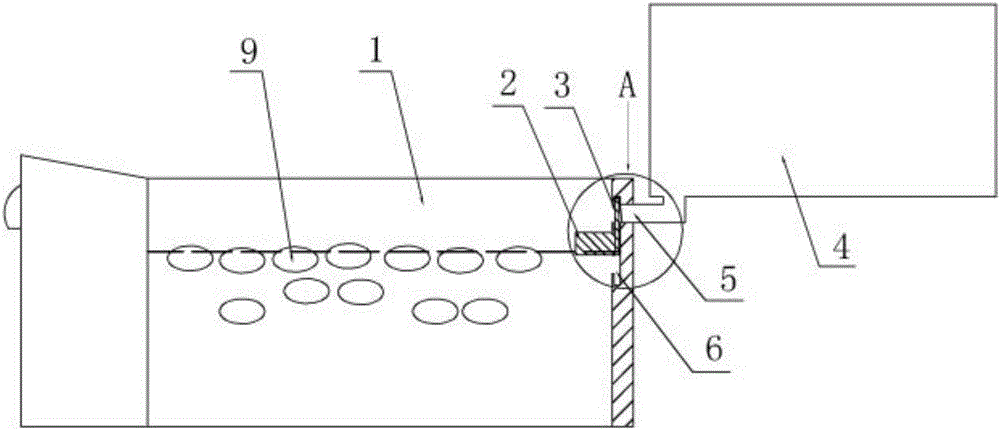

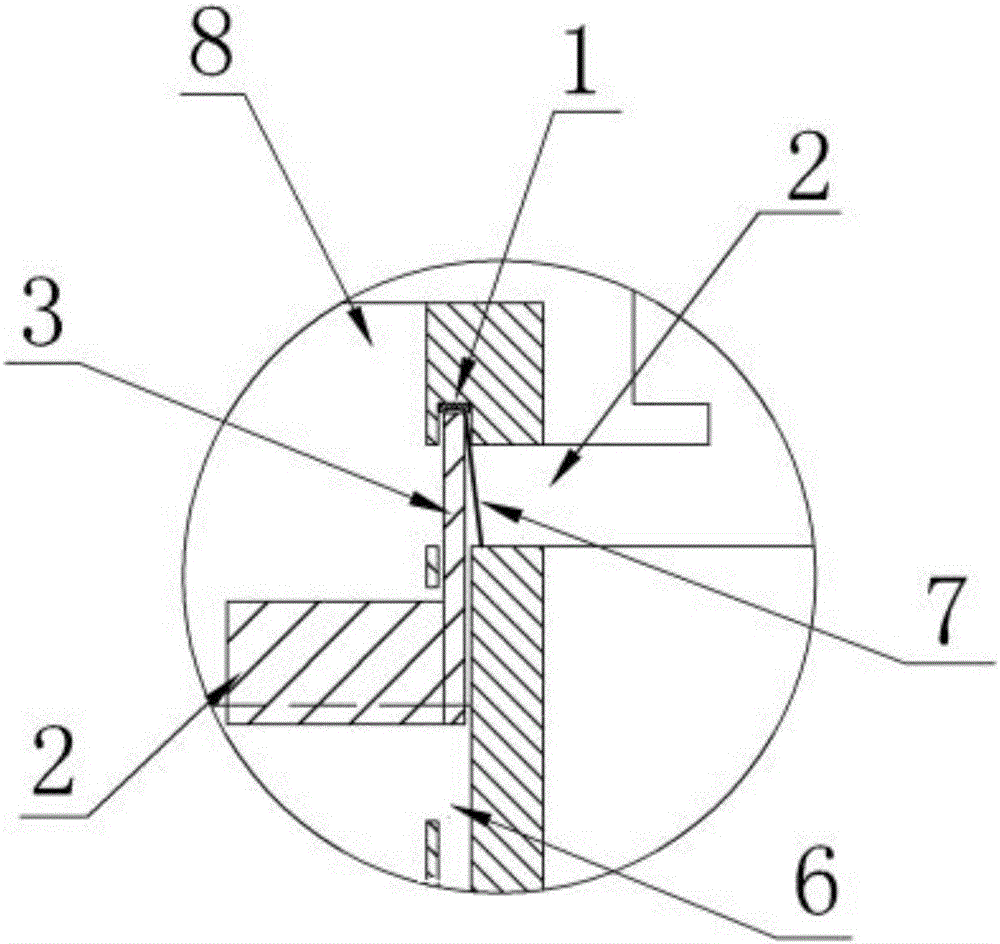

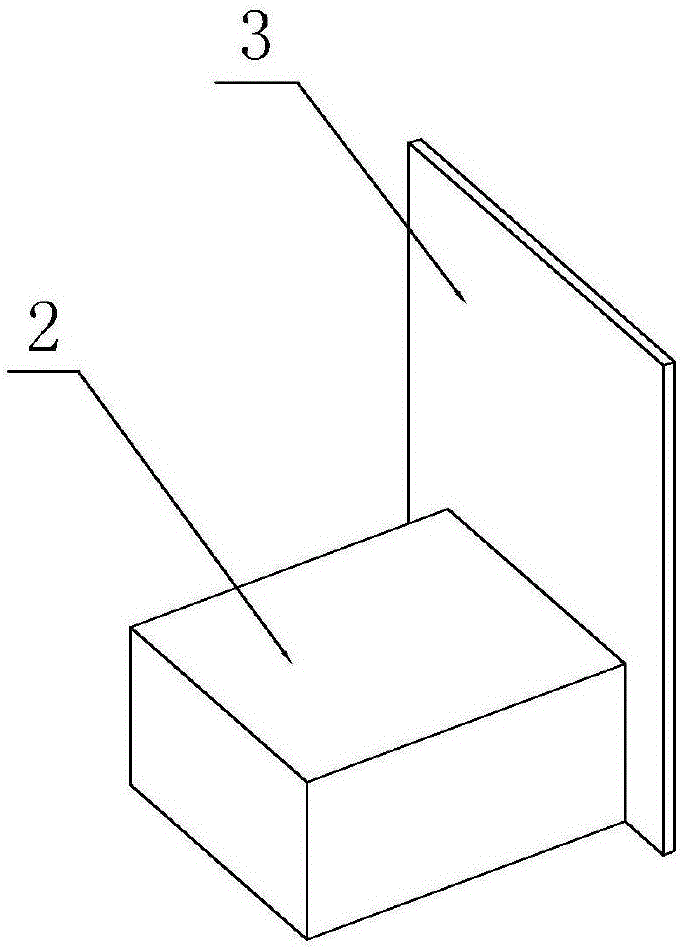

[0018] An automatic water supply device for a cocoon feeder, comprising a cocoon feeder water tank 1, a through hole 5 is opened on the right side wall of the cocoon feeder water tank 1, and one end of the through hole 5 is connected to a water tank located above the cocoon feeder water tank 1. Water supply tank 4, the inside of the right side wall of the cocoon feeder water tank 1 is provided with chute 6 around the through hole 5, the chute 6 is slidably connected to the water retaining plate 3, and the bottom of the left side of the water retaining plate 3 is fixedly connected to the floating Block 2, the top of the right side is connected to the top of the waterproof cloth 7, and the bottom of the waterproof cloth 7 is sealed and connected with the bottom of the through hole 5.

[0019] Furthermore, the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com