Open type profile door and window system

An open-type, profile technology, applied in the direction of window/door frame, leaf frame, etc., can solve the problems that the profile size cannot be too small, the product cannot be thinned, and the product line is wide, so as to omit the closed welding process, Improve overall aesthetics and narrow product lines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

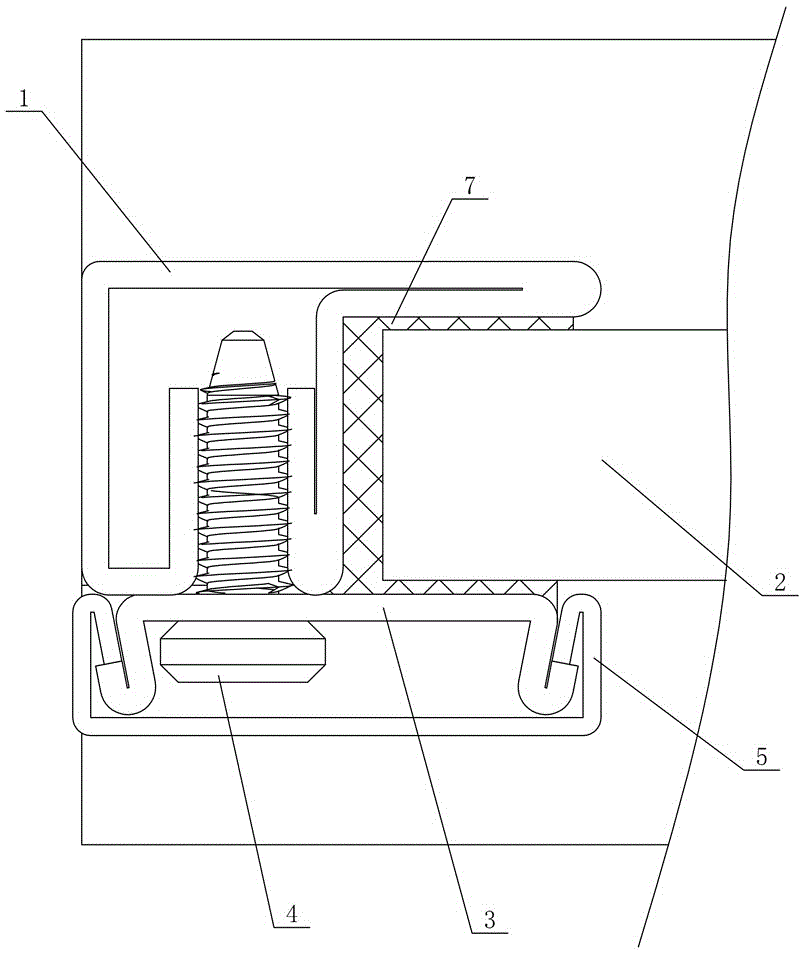

[0045] like figure 1 and figure 2 As shown, the first embodiment of the opening profile door and window system of the present invention, the door and window system includes a steel opening frame 1, a plate 2 and a bead 3, the steel opening frame 1 is surrounded by the edge of the plate 2, and the bead 3 and the The opening 11 of the steel opening frame 1 is tightly connected, and the plate 2 is located between the bead 3 and the steel opening frame 1 . In this structure, the plate 2 is press-fitted on the inner edge of the steel opening frame 1 through the bead 3, and the frame structure adopts the welding of the steel opening frame 1, that is, the steel opening frame 1 does not have a closed mouth, and after it is cold-formed, it can be directly Spraying, no need to weld at the closed part, the largest consumables are reduced, greatly reducing the cost, and there is no need to place magnetic rods in the profile, which makes the profile size smaller, the product line narrowe...

Embodiment 2

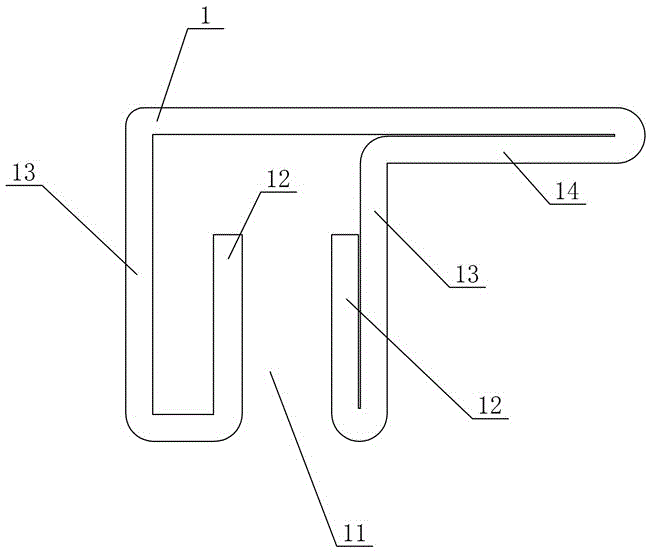

[0052] like image 3 and Figure 4As shown, the second embodiment of the open profile door and window system of the present invention, the door and window system is basically the same as Embodiment 1, the only difference is that in this embodiment, the ends of the two connecting sides 13 are bent together to form two stoppers. part 14, the two stop parts 14 are located on both sides of the opening 11 and on the same straight line. The steel opening frame 1 of this structure is suitable for connecting boards 2 arranged on the same line on both sides, and the two boards 2 respectively press against two stoppers 14 .

Embodiment 3

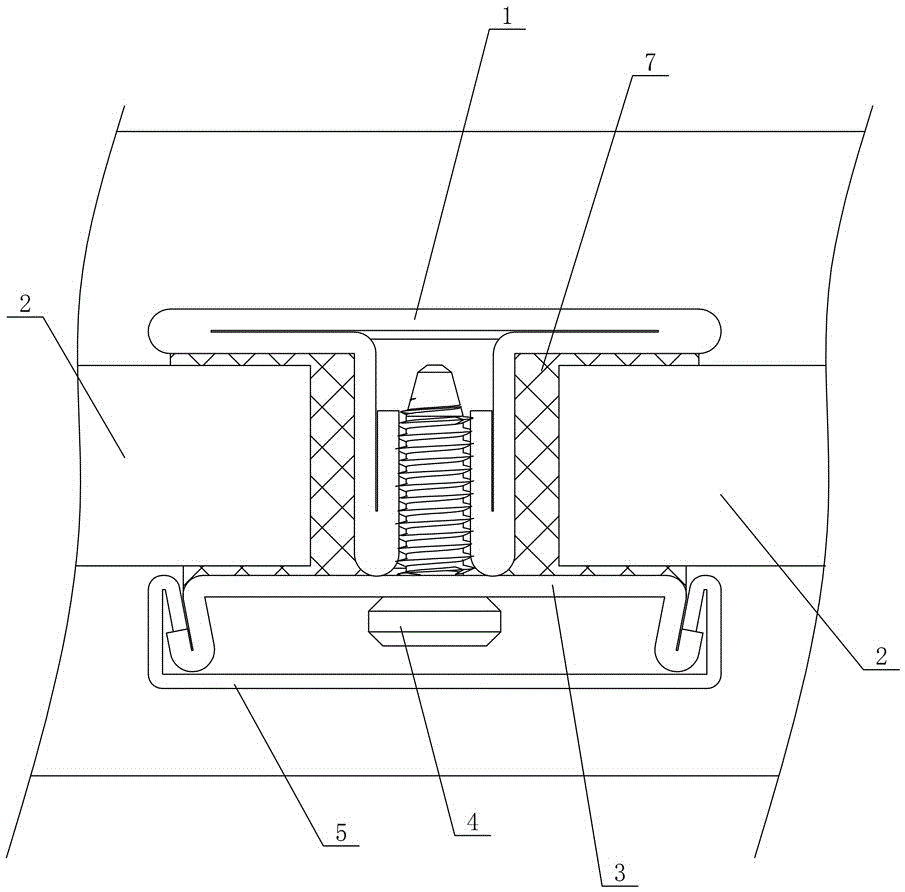

[0054] like Figure 5 and Figure 6 As shown, the third embodiment of the open profile door and window system of the present invention, the door and window system is basically the same as Embodiment 1, the only difference is that in this embodiment, the two fracture sides 12 are perpendicular to the screwing direction of the bolt 4, The screw head of the bolt 4 hangs on the inner walls of the two fracture sides 12, the threaded section of the bolt 4 protrudes from the opening 11 and the bead 3, and then is fastened and connected by the nut 6, and the nut 6 drives the bead 3 to drive the plate 2 to be pressed against the stopper 14. In this structure, the screw heads of the bolt 4 are first hung on the inner walls of the two fracture sides 12, then the threaded section of the bolt 4 extends out of the bead 3, and then the nut 6 and the threaded section of the bolt 4 are tightened to make the bead 3 Pressing the panel 2 and driving the panel 2 to press against the blocking por...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com