Grouting material feeding device of shield machine

A technology of grouting materials and shield machines, which is applied in loading/unloading, transportation and packaging, mining equipment, etc. It can solve problems such as poor feeding of silos, increased number of times of transportation, and space restrictions, so as to reduce transportation load and cost, the effect of fewer times of material transportation, and the smooth discharge of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the first embodiment of the accompanying drawings.

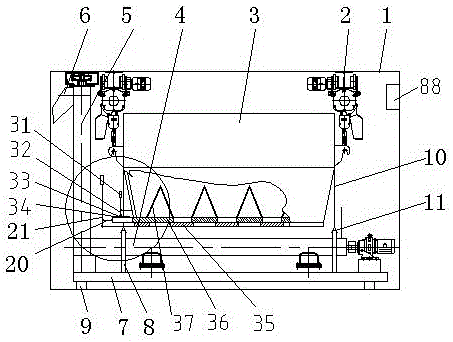

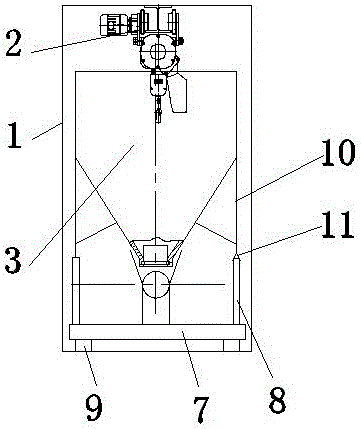

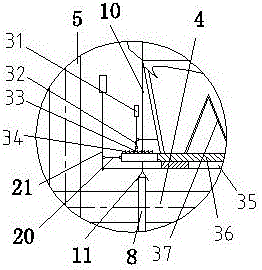

[0019] A shield machine grouting material feeding device, comprising a frame 1, a crane 2 connected to the top of the frame 1, a silo 3 connected to the crane 2, a material receiving screw conveyor 4, and a vertical screw conveyor 5 And the discharge port 6, the receiving screw conveyor 4 is located below the silo 3, the lower end of the vertical screw conveyor 5 is connected to the left side of the receiving screw conveyor 4, and the discharge port 6 is connected to the upper end of the vertical screw conveyor 5 , which is characterized in that the grouting material feeding device of the shield machine also includes a grid blanking device, a bin positioner and a weighing device. The grid blanking device is located at the bottom of the bunker 3 and is connected to the bunker 3. The silo locator is located below the silo 3 , the weighin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com