A Curved Composite Silent Drain Pipe

A technology for drainage pipes and water pipes, applied to pipes, pipe components, rigid pipes, etc., can solve the problems of water pipe damage, lack of sound insulation structure, water pipe blockage, etc., achieve good sound insulation effect, improve operation quality, and ensure normal use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some of the embodiments of the present invention, not all of them.

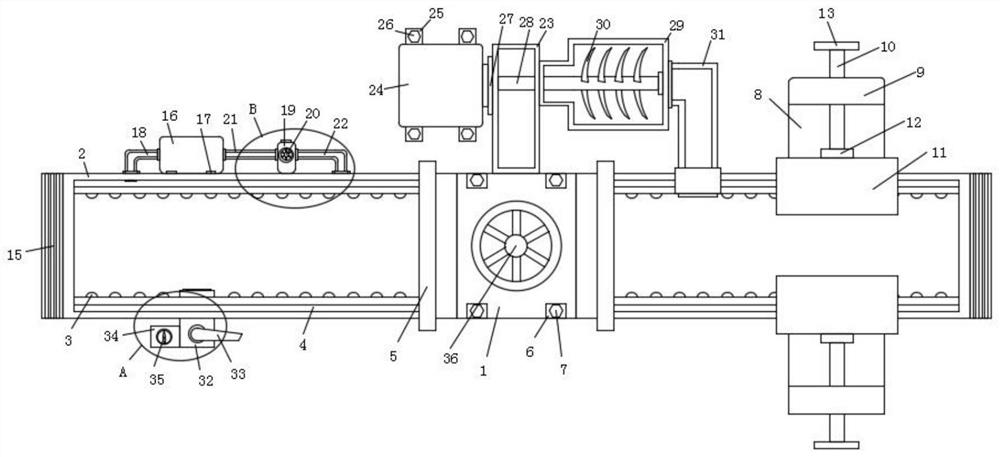

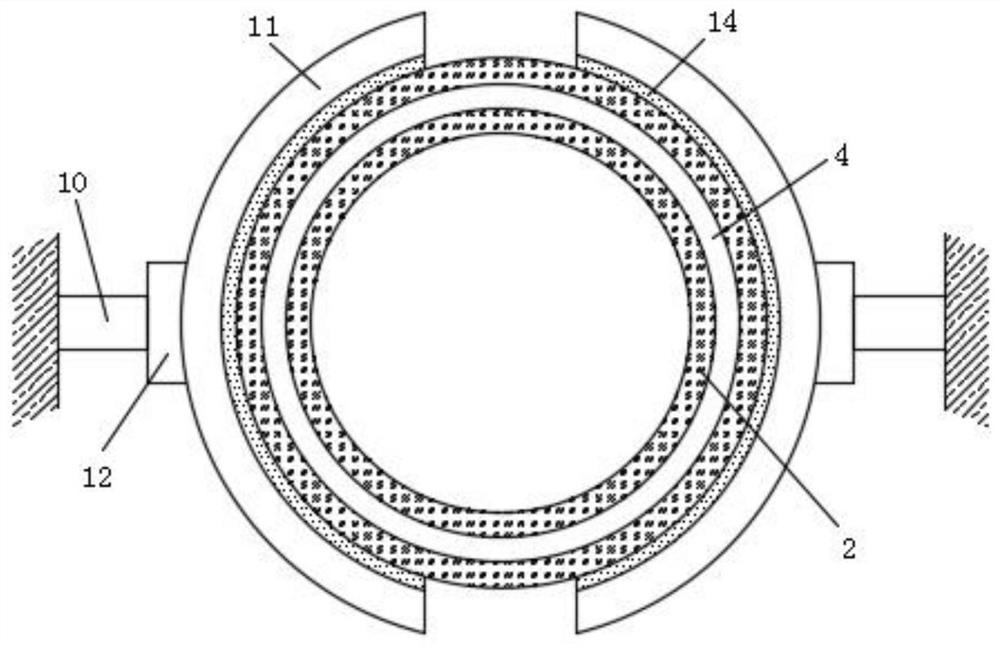

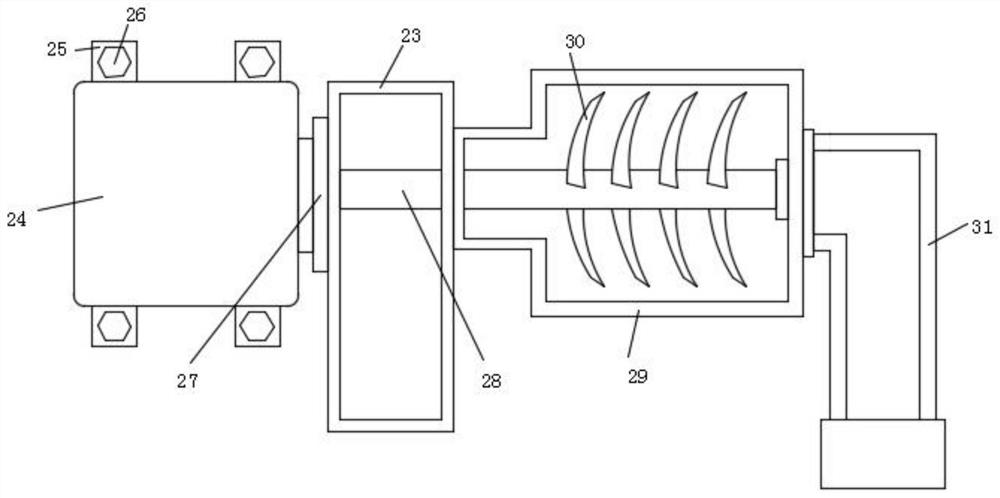

[0026] refer to Figure 1-5, a curved composite silent drainage pipe, including a three-way valve 1, the specific model of the three-way valve 1 is LT-STQF, and the main body is made of stainless steel, which improves its durability and avoids corrosion after being exposed to water. The two ends of the through valve 1 are symmetrically provided with two water pipe bodies 2 made of stainless steel. The inner wall of the water pipe body 2 is fixed with a plurality of water flow damping blocks 3, and the outer wall of the water pipe body 2 is provided with a cavity 4. The sound of water flow inside the water pipe body 2 can be effectively blocked by means ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com