Integral full-circumference nozzle chamber of high back pressure steam turbine

A technology for nozzle chambers and steam turbines, applied to mechanical equipment, engine components, machines/engines, etc., can solve problems such as loss of steam intake and reduce efficiency of steam turbines, and achieve the effects of eliminating loss of intake steam, improving efficiency and quick start-up performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

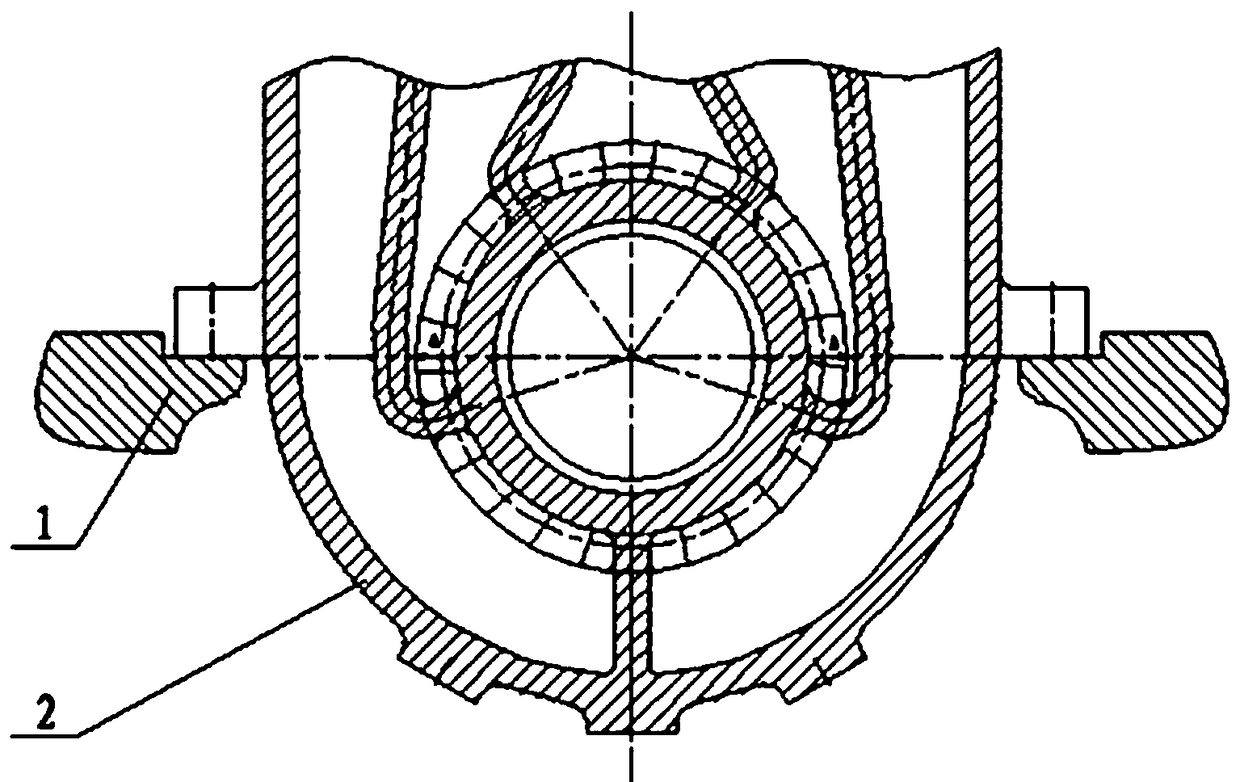

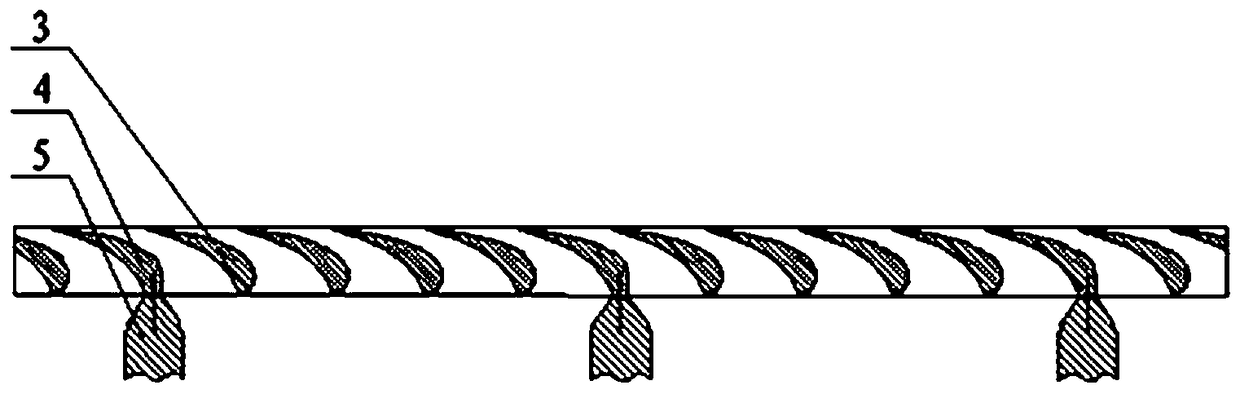

[0009] Referring to each figure, a high back pressure steam turbine has a whole-circumferential nozzle chamber, including an outer cylinder block 1 and a nozzle chamber 2. The outer walls of the nozzle chamber 2 are symmetrically provided with lugs at both ends, and the nozzle chamber 2 is supported on the outer cylinder through the lugs at both ends. At the middle parting surface of the lower half of the cylinder body 1, the nozzle chamber 2 adopts an integral casting structure, and the nozzle chamber 2 is divided into five nozzle chambers, which form a ring structure, and each of the five nozzle chambers is equipped with a group of nozzles A group of nozzles consists of at least four common nozzles 3, the distance between every two adjacent common nozzles 3 is equal, and a partition rib 5 is provided between the nozzle chamber and the nozzle chamber to separate Flat nozzles 4 are arranged on the ribs 5 .

[0010] The high back pressure steam turbine has an integral whole-cir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com