Blockage-prevention winding-prevention centrifugal type self-suction sewage pump

A self-priming sewage pump and anti-winding technology, which is applied in the field of centrifugal pumps, can solve problems such as easy-to-wind blades, failure to work normally, and pump performance degradation, so as to improve efficiency and service life, reliable normal operation, and eliminate winding and blockage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

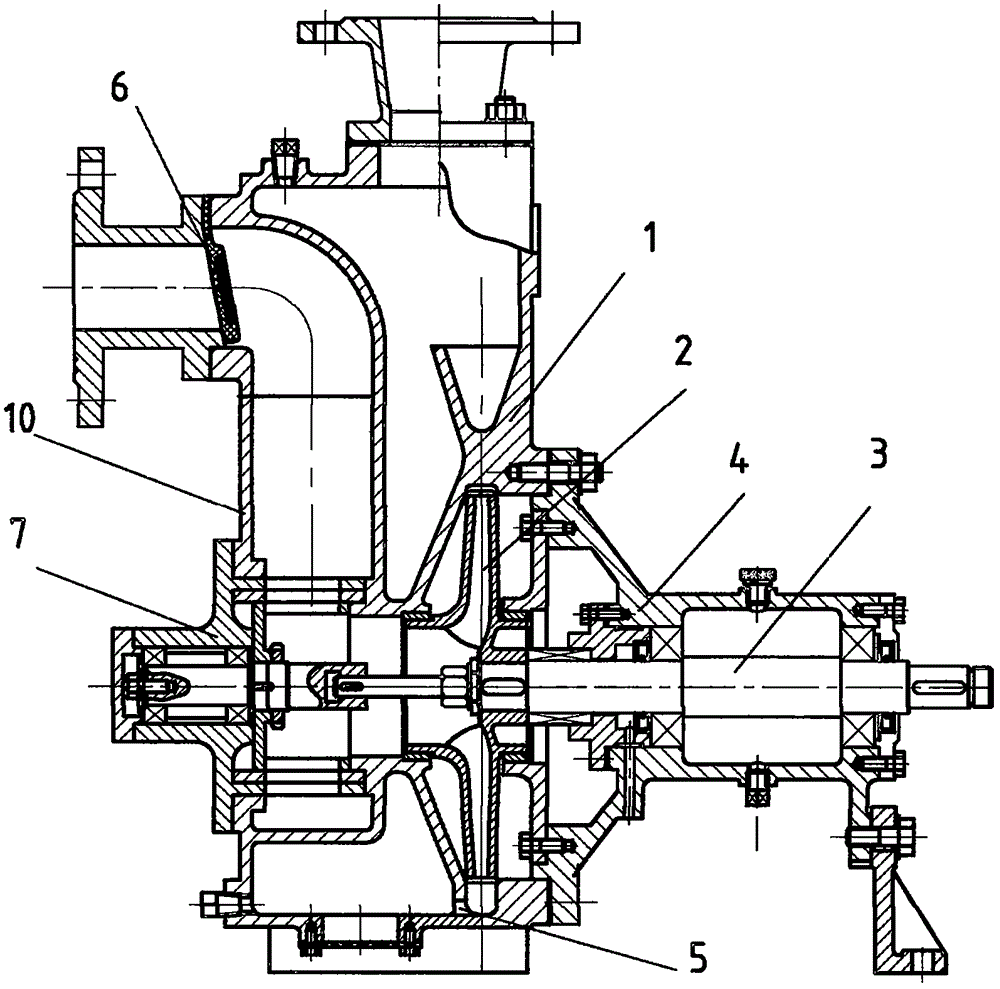

[0031] figure 1 It is a structural diagram of an embodiment of an anti-clogging and anti-winding centrifugal self-priming sewage pump.

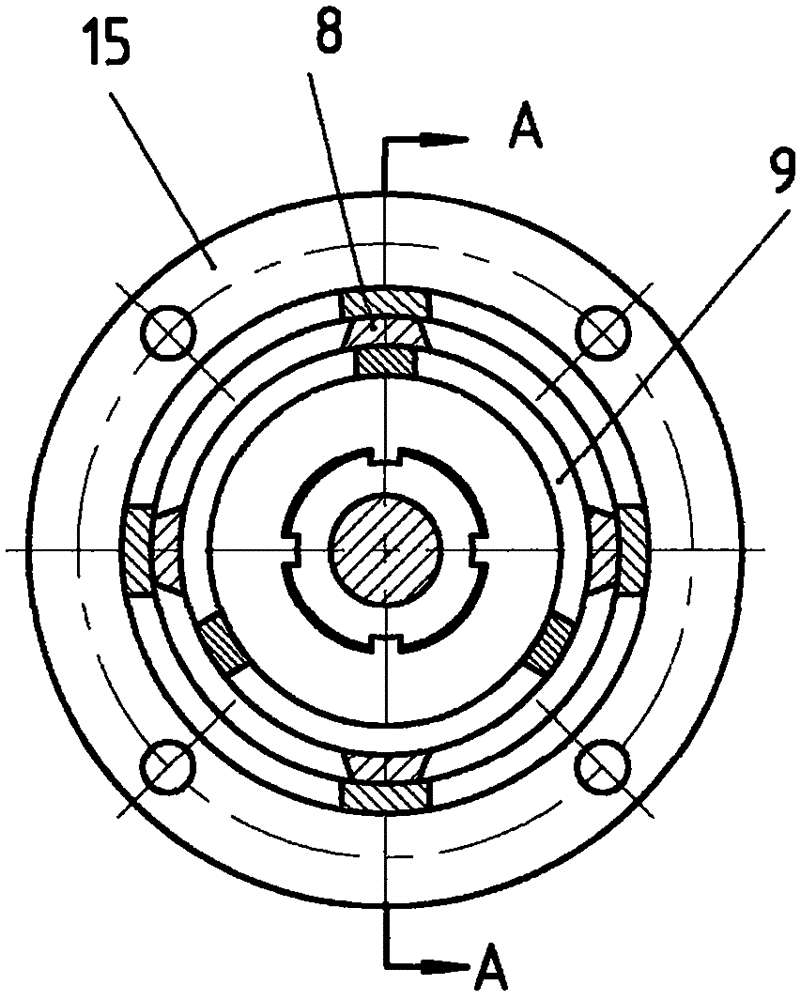

[0032] The figure shows: anti-clogging and anti-winding centrifugal self-priming sewage pump, including pump body 1, impeller 2 installed in the vortex chamber of pump body 1, pump shaft 3 fixedly connected to impeller 2, and suspension supporting pump shaft 3 4. The pump body 1 is also provided with a suction port, a suction channel, a discharge port, an air-water separation chamber and a water return hole 5, wherein the suction port is provided with a suction check valve 6, and the impeller 2 enters the suction channel of the pump body 1. A sundry cutter 7 coaxial with the impeller 2 is arranged in front of the nozzle, which is fixed on the front partition 10 of the pump body 1 and consists of a static knife frame 8 and a cutter wheel 9 .

[0033] The cutter wheel 9 is fixed on the central shaft 14 coaxial with the pump shaft 3, the centra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com