A compressor assembly

A technology for compressors and compressor shells, which is applied in the field of compressors, and can solve problems such as unreliable operation or shutdown of compressors, rising discharge temperature of compressors, and increased workload, so as to reduce noise and reduce exhaust Temperature, the effect of reducing the pressure ratio of the whole machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

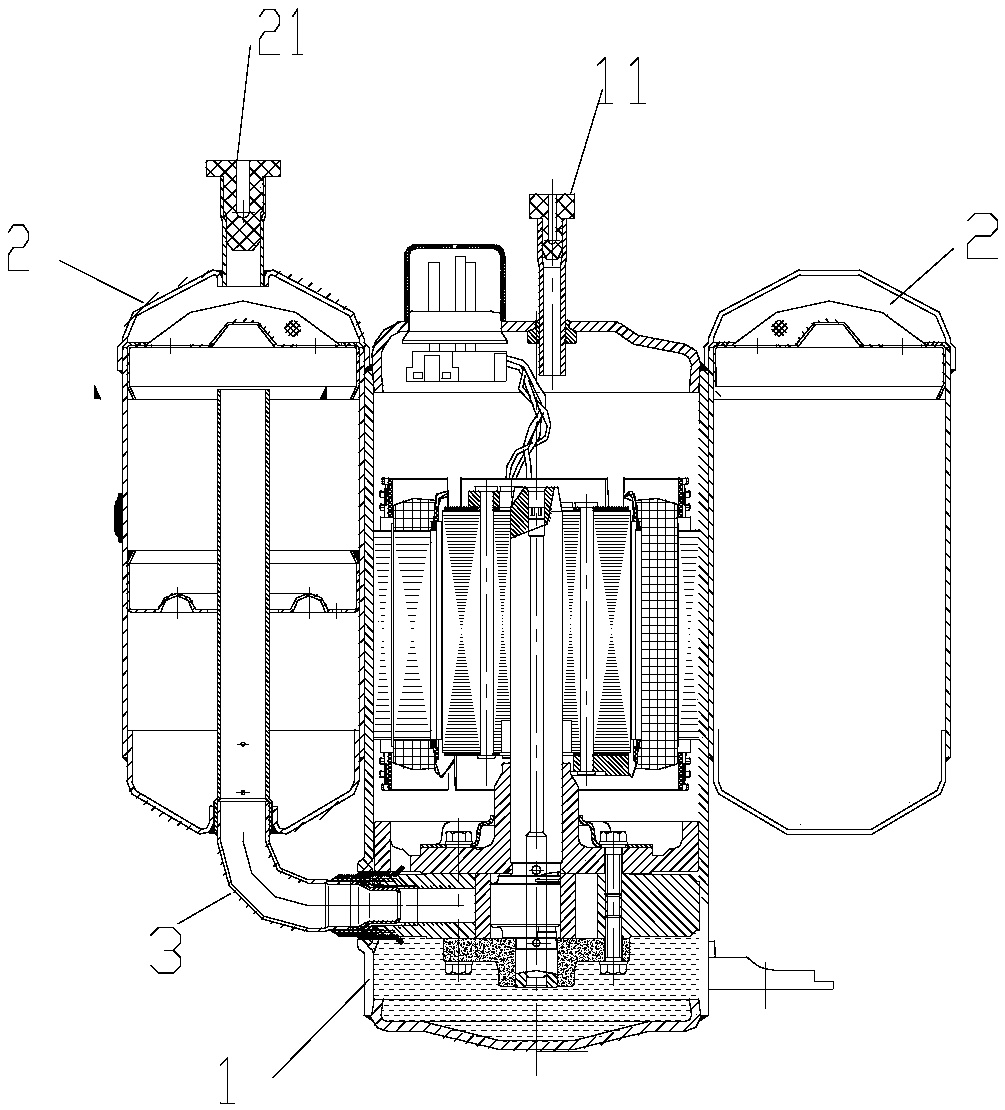

[0052] 1. The compressor assembly includes liquid storage tank 2, terminal, suction pipe 21, exhaust pipe 11, connecting pipe 3 and other parts;

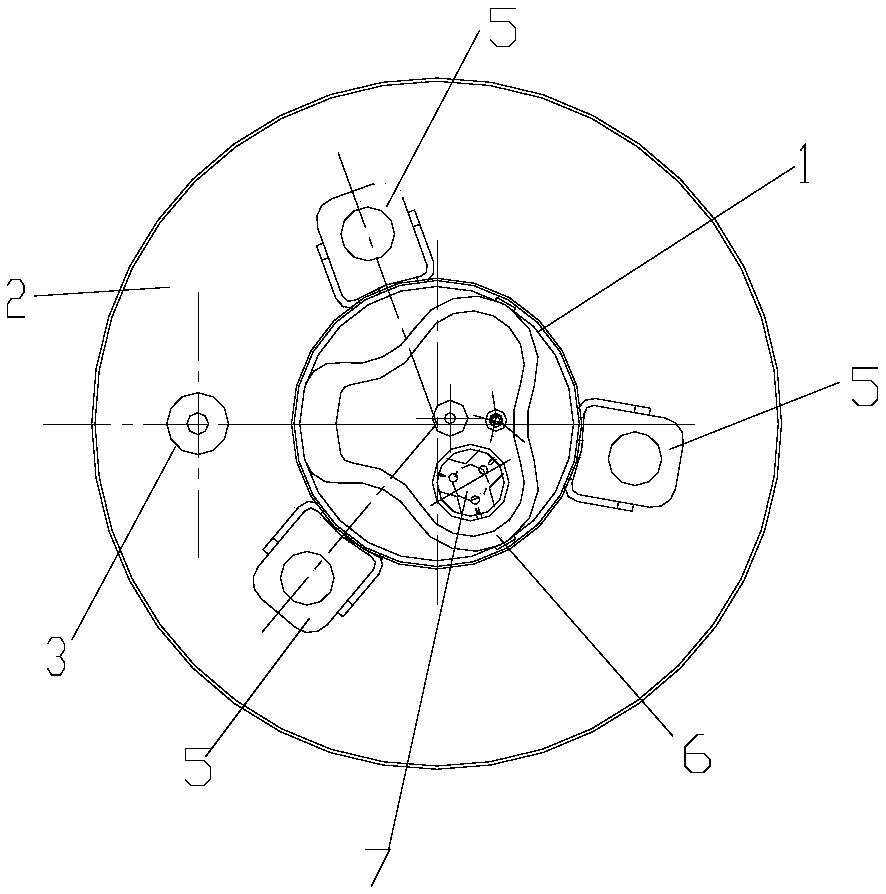

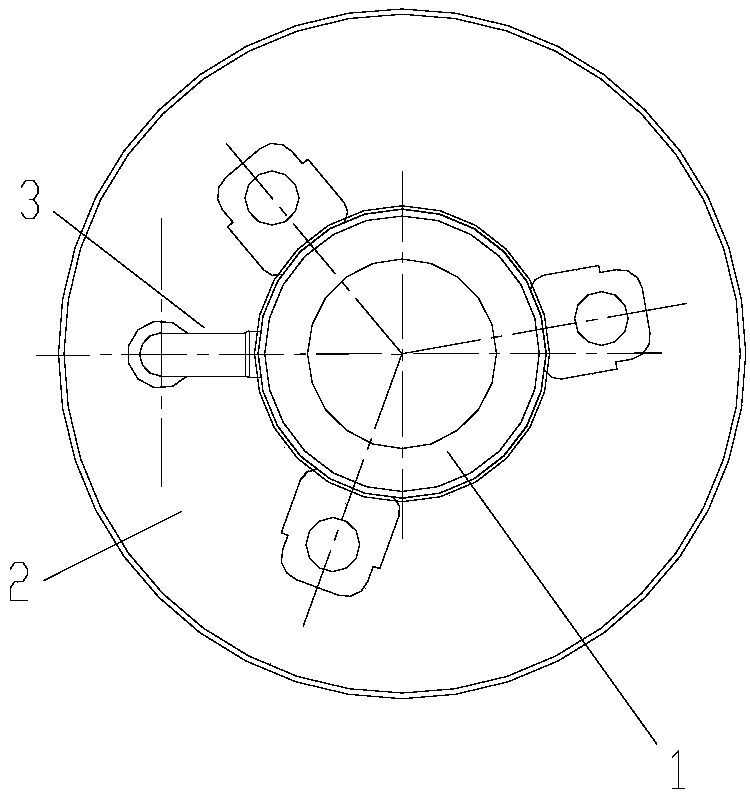

[0053] 2. If Figure 1-3 The shown compressor housing and liquid storage tank are designed as one piece, cast and molded; the liquid storage tank and compressor housing can also be non-cast, and the heat-conducting adhesive is used to seamlessly bond the two to the compressor housing;

[0054] 3. The compressor cavity is cylindrical, and the liquid storage tank and the compressor are integrated into a circular column shape. The upper end of the liquid storage tank has a suction pipe 21, and the lower end has a connecting pipe 3 connected to the suction port of the compressor cavity;

[0055] 4. The compressor liquid storage tank is designed as a concentric structure with the compressor cavity;

[0056] 5. The size of the compressor liquid storage tank can be designed with different radii according to the size of the system, but the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com