Heat pump system and car with same

A technology of heat pump system and heat exchanger, which is applied in the field of automobiles, can solve the problems of low heat exchange efficiency and single flow direction of refrigerant, and achieve the effect of improving heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

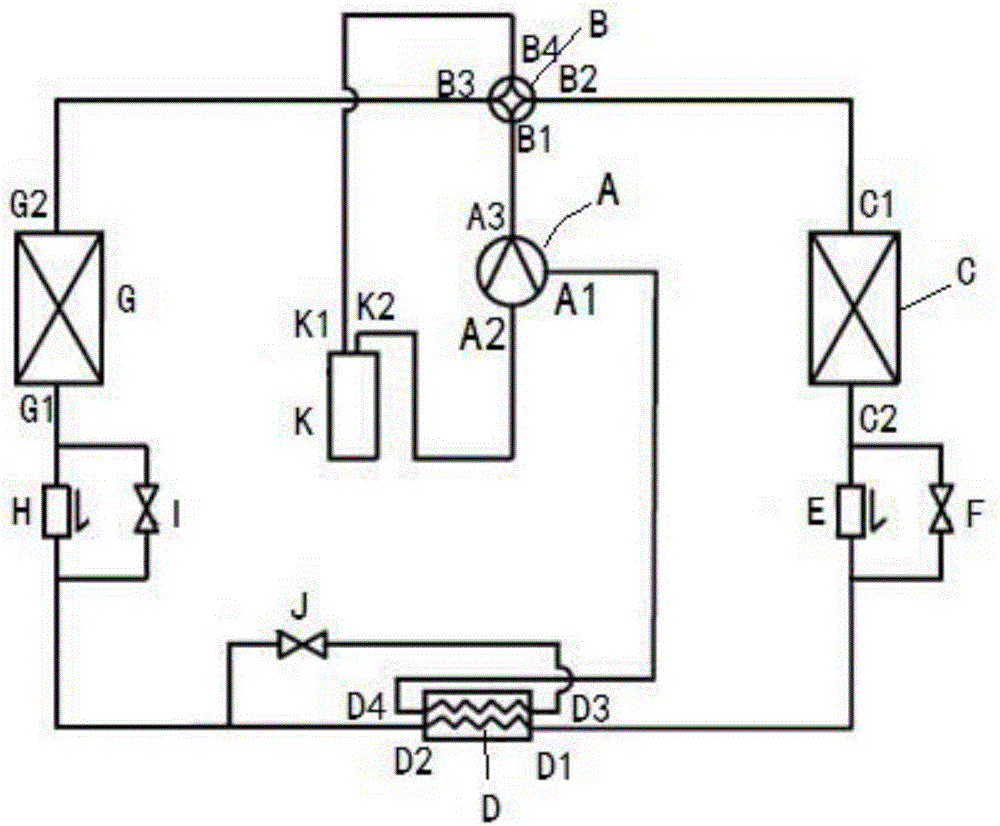

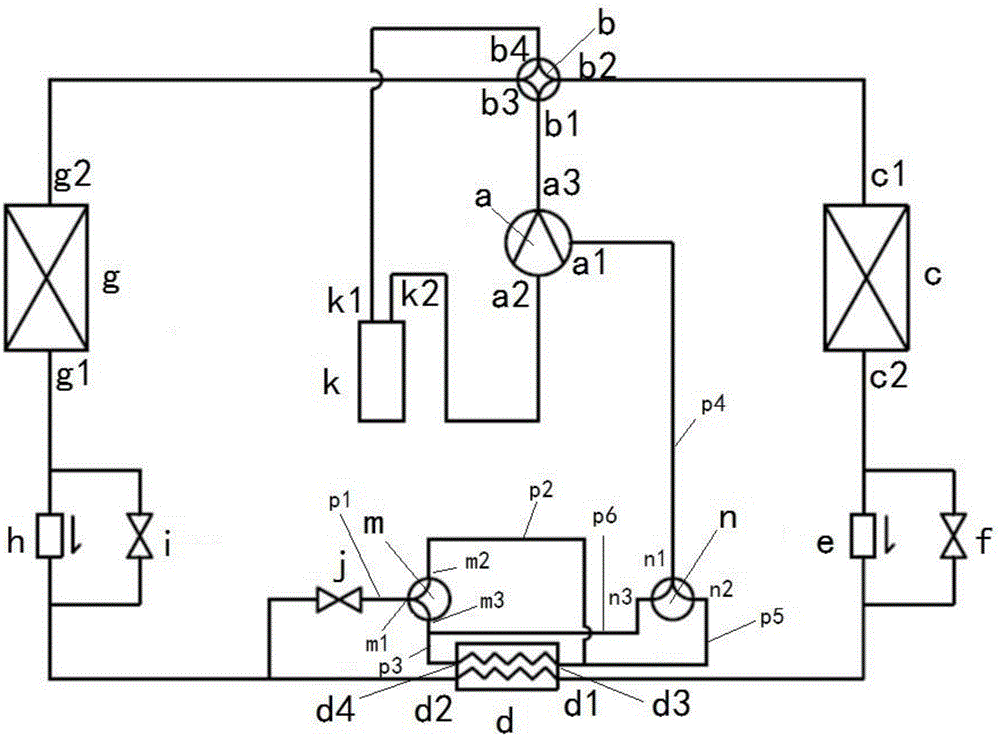

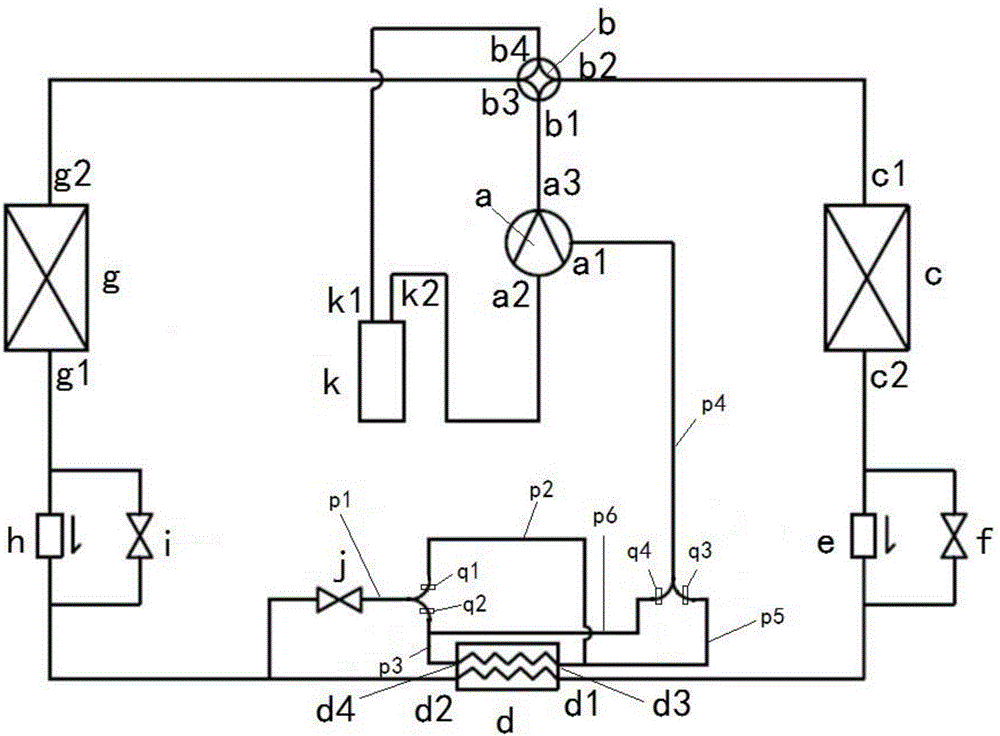

[0066] This embodiment provides a heat pump system, such as figure 2 shown, including:

[0067] A compressor a has a first compressor inlet a1, a second compressor inlet a2 and a compressor outlet a3;

[0068] The four-way structure b has a first opening b1, a second opening b2, a third opening b3 and a fourth opening b4, the first opening b1 communicates with the compressor outlet a3, the fourth opening b4 communicates with the The second compressor inlet a2 is in communication; the four-way structure b has a first state in which the first opening b1 is in communication with the second opening b2, and the third opening b3 is in communication with the fourth opening b4 , and a second state in which the first opening b1 communicates with the third opening b3, and the second opening b2 communicates with the fourth opening b4;

[0069] a first heat exchanger c, having a first heat exchanger inlet c1 communicating with said second opening b2, and a first heat exchanger outlet c...

Embodiment 2

[0109] This embodiment provides an automobile installed with the heat pump system described in Embodiment 1.

[0110] The automobile in this embodiment, since the heat pump system in Embodiment 1 is installed, naturally has all the advantages brought by the installation of the above heat pump system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com