Side plate of heat exchanger, parallel flow heat exchanger and bus air-conditioning system

A parallel flow heat exchanger and air conditioning system technology, applied in the direction of heat exchanger shell, evaporator/condenser, heat exchange equipment, etc., can solve the problem of difficulty in ensuring the installation strength and reliability of the heat exchanger and reliability are difficult to guarantee, to achieve the effect of improving the fixing method, simple structure, improving strength and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

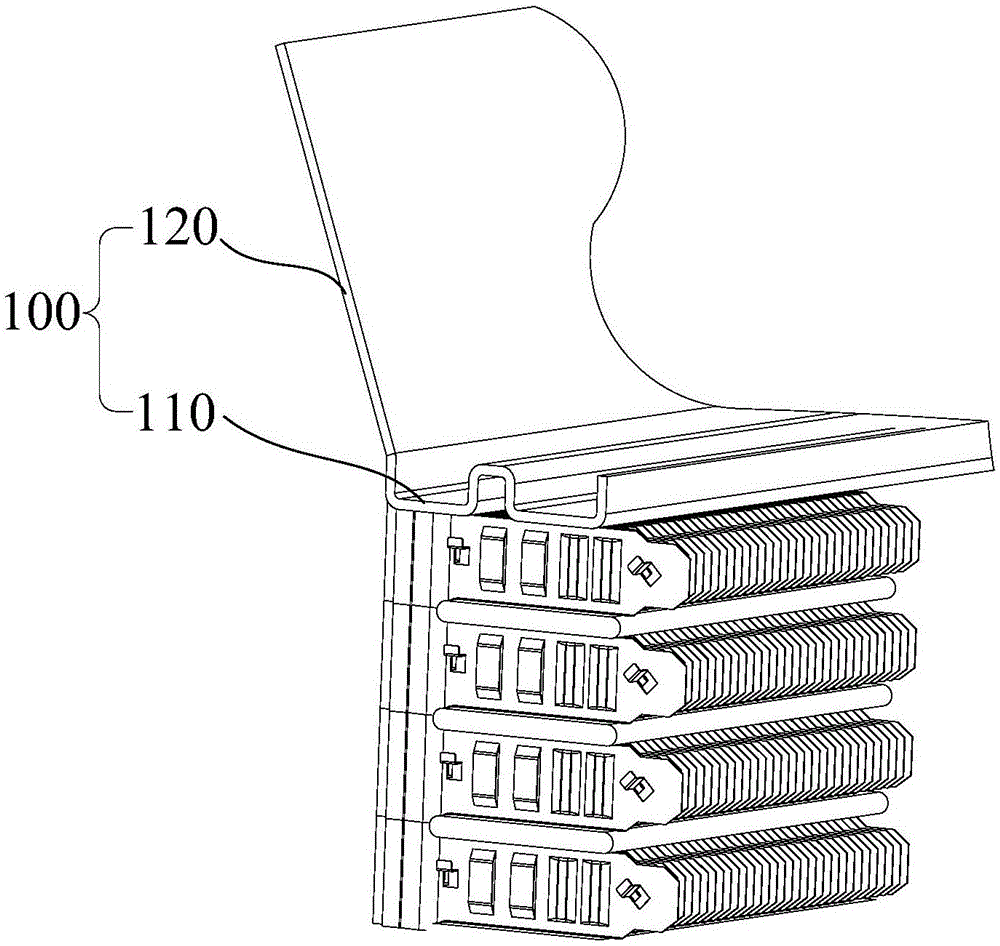

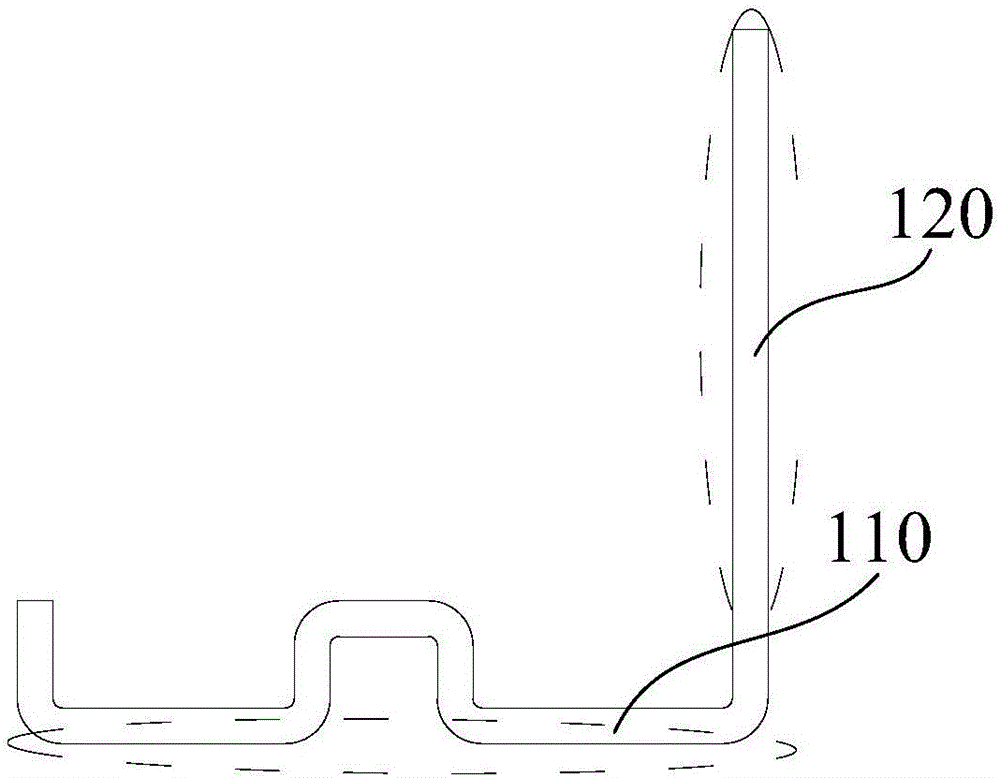

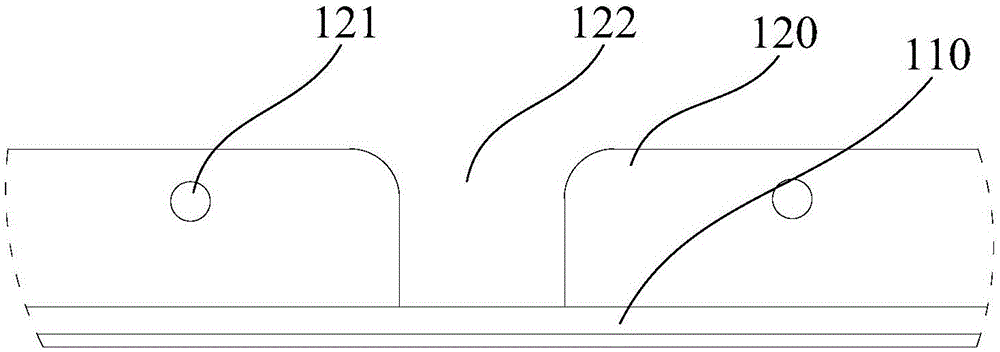

[0067] Corresponding to this embodiment, the embodiment of the present invention also provides a bus air conditioning system, including the parallel flow heat exchanger 200 of this embodiment, which is applied to the top-mounted passenger car air conditioner of the bus air conditioning system, wherein the supporting frame 240 is used for exchanging The heat exchanger is fixed along the length direction of the header 210, and at the same time, the inclined setting of the heat exchanger at different angles can be realized by changing the direction of the header 210 installed on the support frame 240. The side plate 100 is used to align the heat exchanger along the The longitudinal direction of the flat tube 220 is fixed, so that the whole heat exchanger is reliably fixed.

[0068] combine Figure 5 and Image 6 , The heat exchanger is compact in structure, fixed in the horizontal and vertical directions, and can be installed at an angle of 0° to 90°, thereby reducing the height...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com