An inspection equipment for product size and deformation

A technology for testing equipment and deformation, applied in measuring devices, instruments, and optical devices, etc., can solve the problems of shape and size limitations of the tested product, and achieve the effects of convenient operation, high result accuracy, and high detection efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

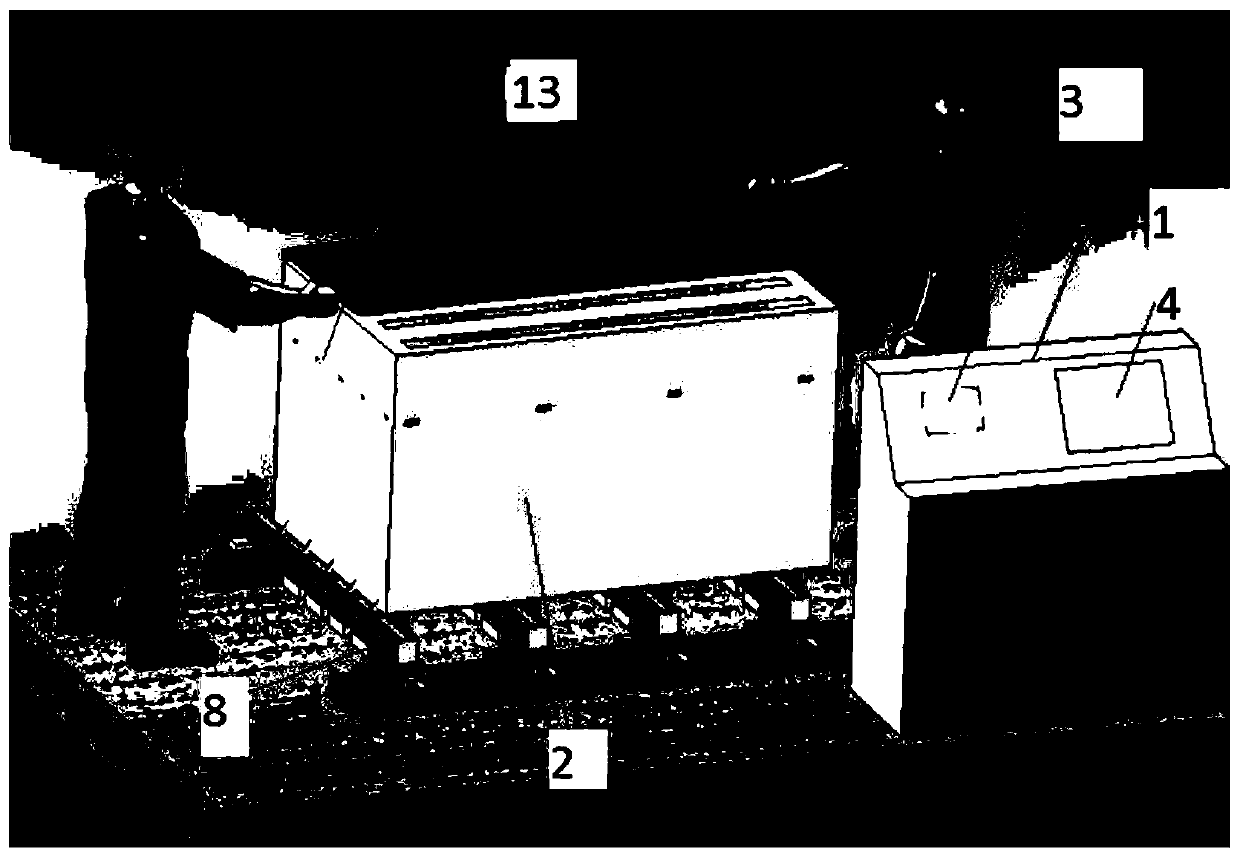

[0016] See attached Figure 1-3 As shown, an automatic inspection equipment for product size and deformation includes a program console 1 and an automatic inspection platform 2 . The program console 1 includes a touch screen 3 and an industrial computer display 4. Input the standard data of the tested product in the touch screen 1, set the position data of important points that need to be detected, and control the position of the automatic inspection platform 2; result.

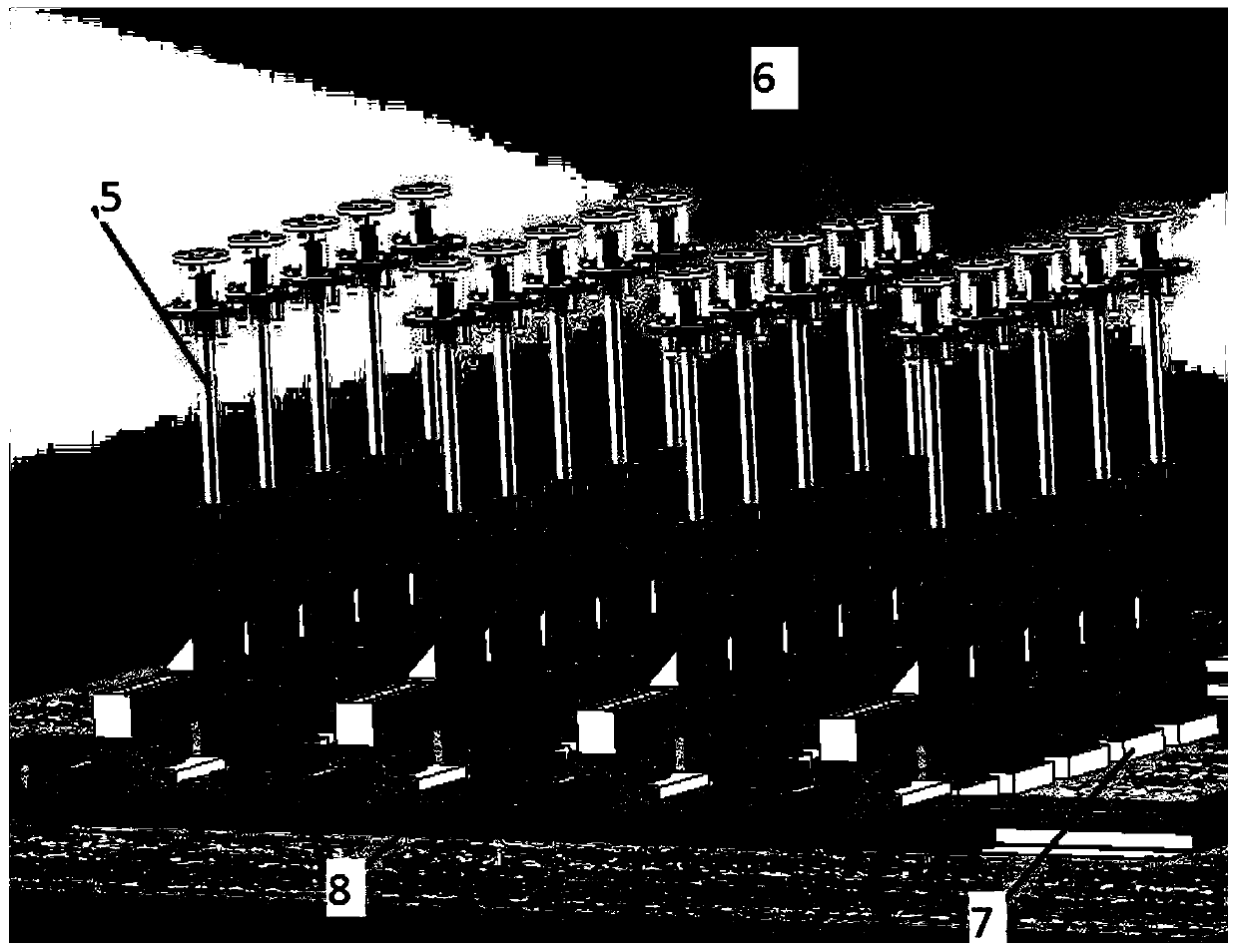

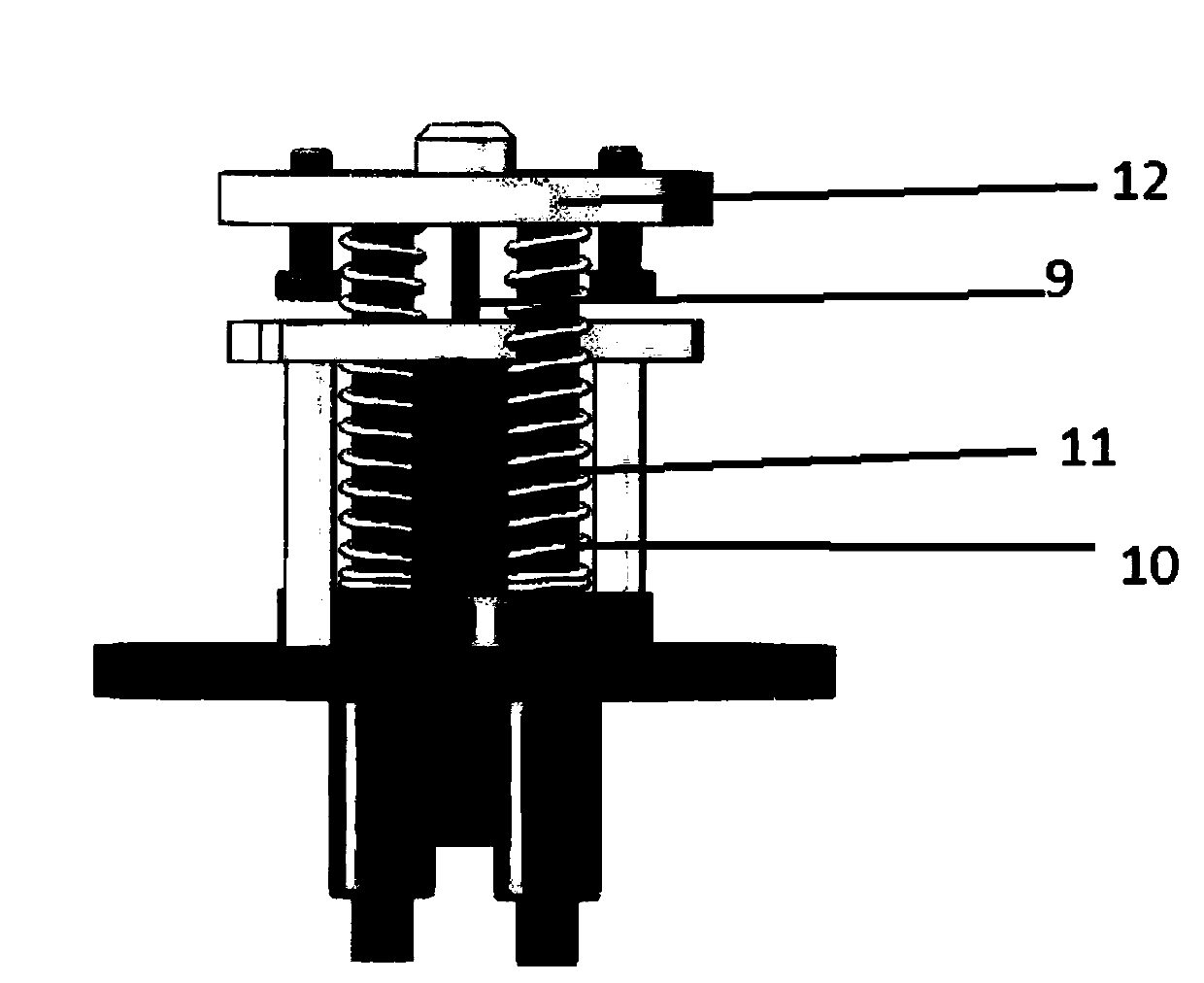

[0017] The automatic inspection platform 2 includes an automatic telescopic cylinder 5 , a sensor and its protection device 6 , a profile building platform 7 , an electric slide rail 8 , and a protective cover 13 . The top of the automatic telescopic cylinder 5 is connected with the sensor and its protection device 6, and the bottom of the automatic telescopic cylinder 5 is connected with the profile building platform 7. The automatic telescopic cylinder 5 can move up and down, and can also move forward and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com