Analysis method for rapidly grading colors of STN liquid crystal screen

An analysis method and technology of LCD screen, applied in sorting and other directions, can solve the problems of poor consistency, difficult to obtain color cast numerical output, different inspection methods, deflection angles and visual differences, etc., to reduce production losses, fast and efficient inspection, Achieving Consistent Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

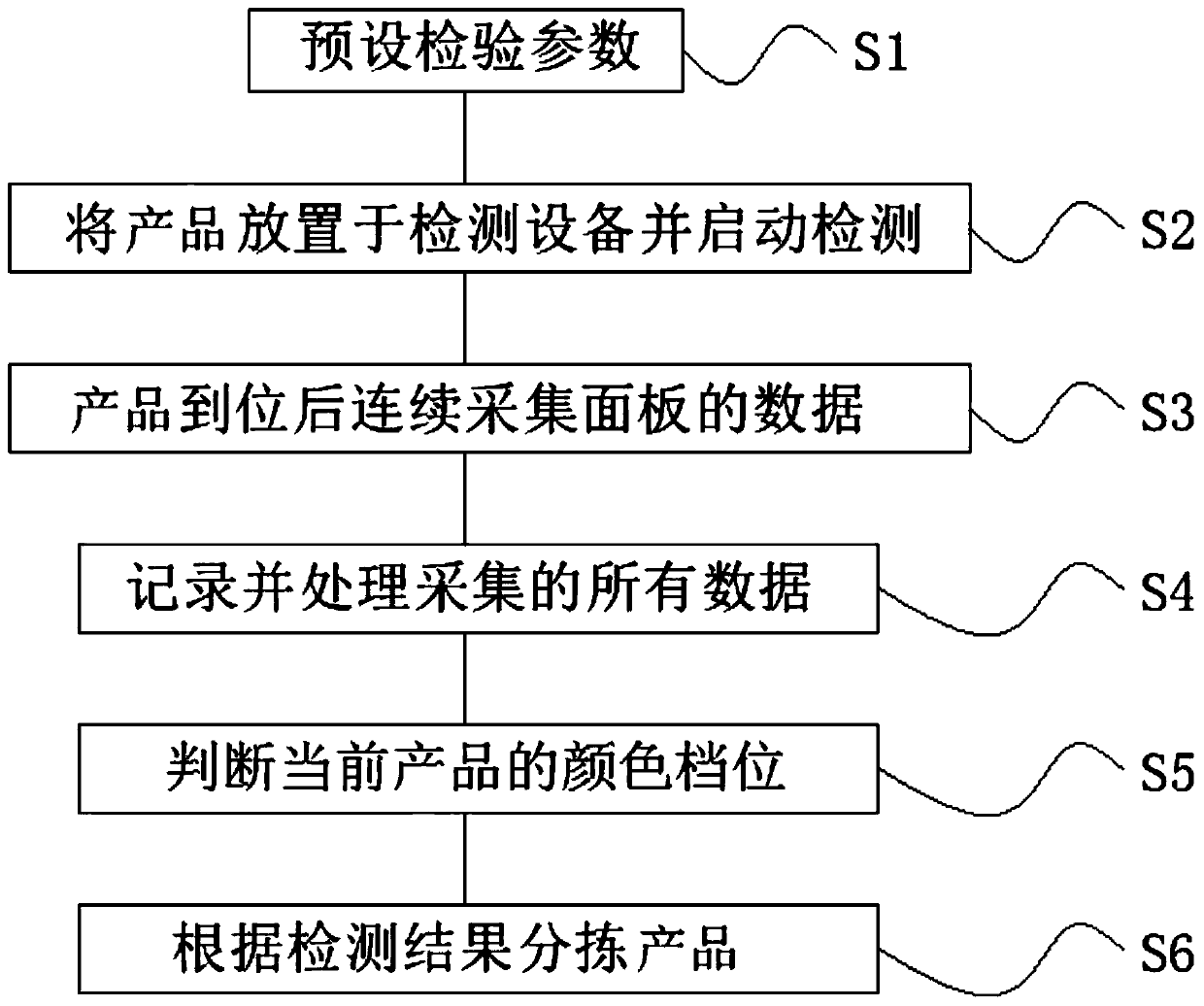

[0035] refer to figure 1 As shown, the present invention provides a kind of analysis method that realizes fast STN liquid crystal screen color classification, comprises the following steps:

[0036] Step S1, preset inspection parameters; wherein, the inspection parameters include control parameters and comparison parameters;

[0037] Step S2, placing the STN liquid crystal screen to be detected on the detection device, and starting the detection;

[0038] Among them, the testing equipment includes a testing platform, a feeding mechanism, a positioning mechanism, a testing mechanism and a feeding mechanism arranged on the testing platform;

[0039] Step S3, after the STN liquid crystal screen is moved into place, continuously collect the data of the STN liquid crystal screen according to the control parameters;

[0040] Step S4, recording a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com