Water pressure testing device

A technology of hydraulic testing and driving devices, which is applied to measuring devices, applying stable tension/pressure to test the strength of materials, instruments, etc., can solve the problems of inaccurate test results and low test efficiency, and reduce the impact of pressure. Guaranteed effectiveness of test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

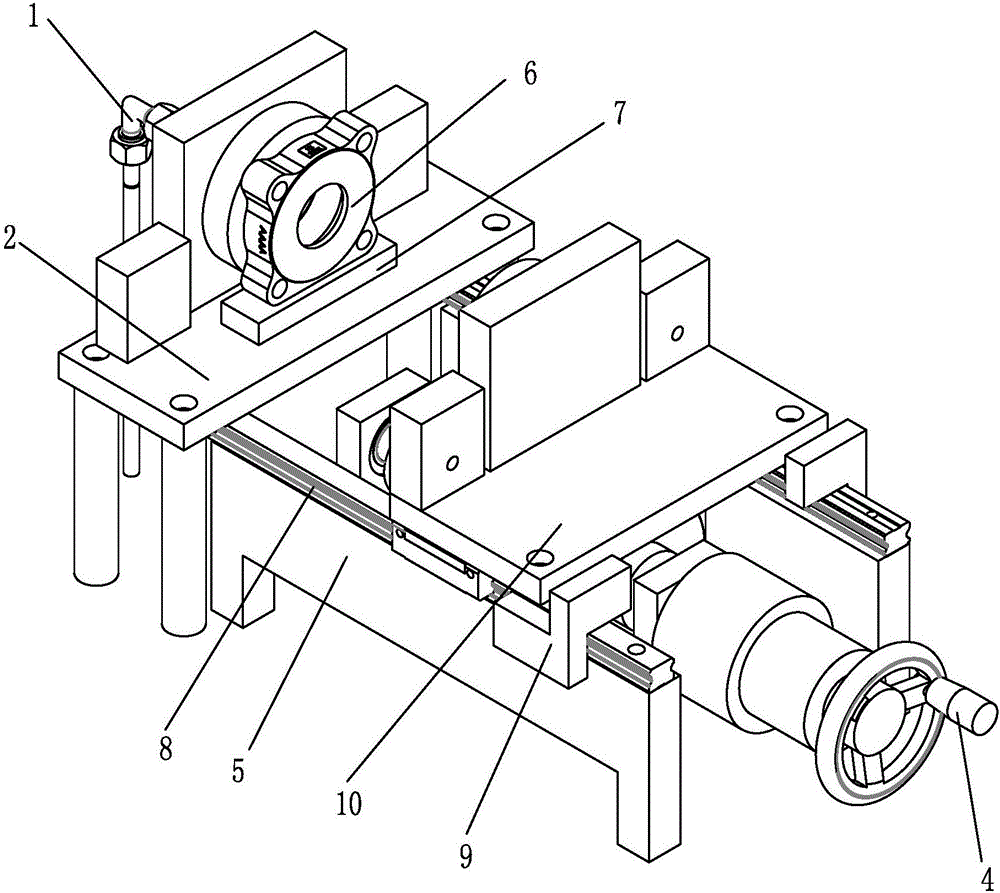

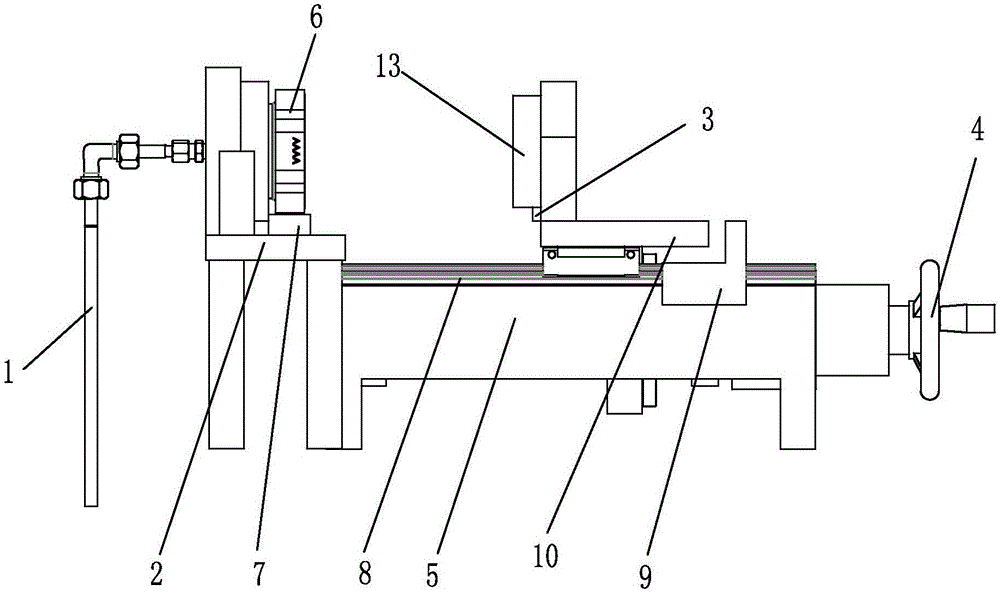

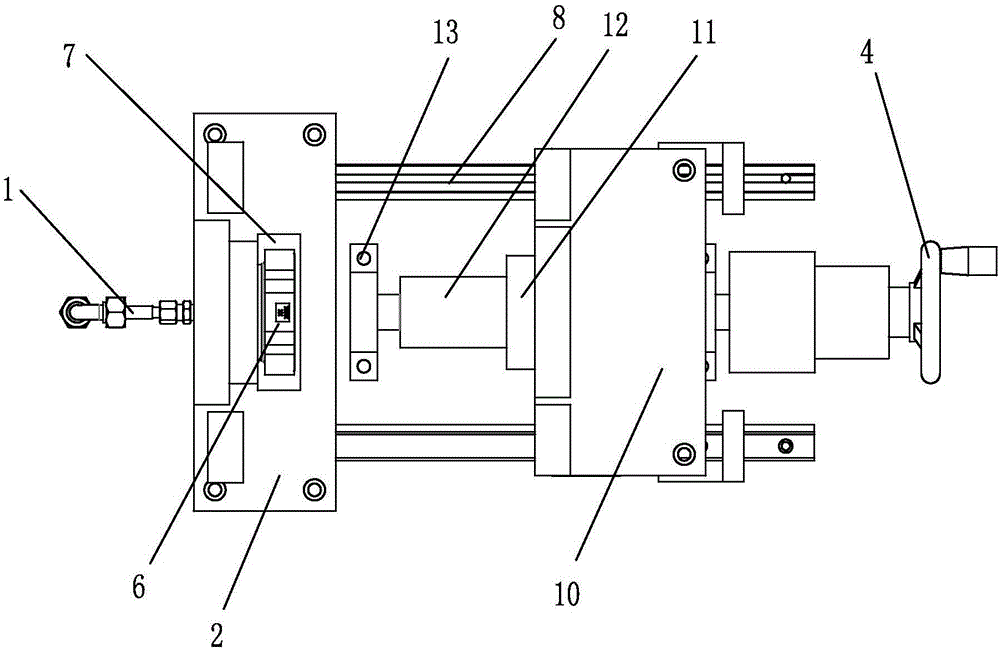

[0012] The present invention will be further described below in conjunction with specific drawings.

[0013] Such as Figure 1 ~ Figure 3 As shown: the hydraulic test device includes a water inlet pipe 1, a workpiece fixing seat 2, a limit block 3, a hand wheel 4, a support 5, a workpiece 6, a limit pad 7, a slide rail 8, a slider 9, Moving seat 10, screw nut 11, screw mandrel 12, pressing block 13 etc.

[0014] Such as Figure 1 ~ Figure 3 As shown, the hydraulic testing device of the present invention includes a support 5, a workpiece holder 2 is installed at one end of the support 5, and the inner side of the workpiece holder 2 is provided with a spacer backing plate 7 for placing the workpiece 6, and the workpiece is fixed. The inner end surface of the seat 2 is in contact with one end surface of the workpiece 6, and the outer end surface of the workpiece fixing seat 2 is connected to the water inlet pipe 1; the other end of the support 5 is provided with a slide rail 8,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com