A pulse cycle life test method for Ni-MH batteries for electric vehicles

A nickel-metal hydride battery, pulse cycle technology, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problems of unimproved electrolyte water electrolysis, low accuracy of test results, high cost investment, etc., and achieve short test cycle and improved Acceptability, the effect of reducing investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

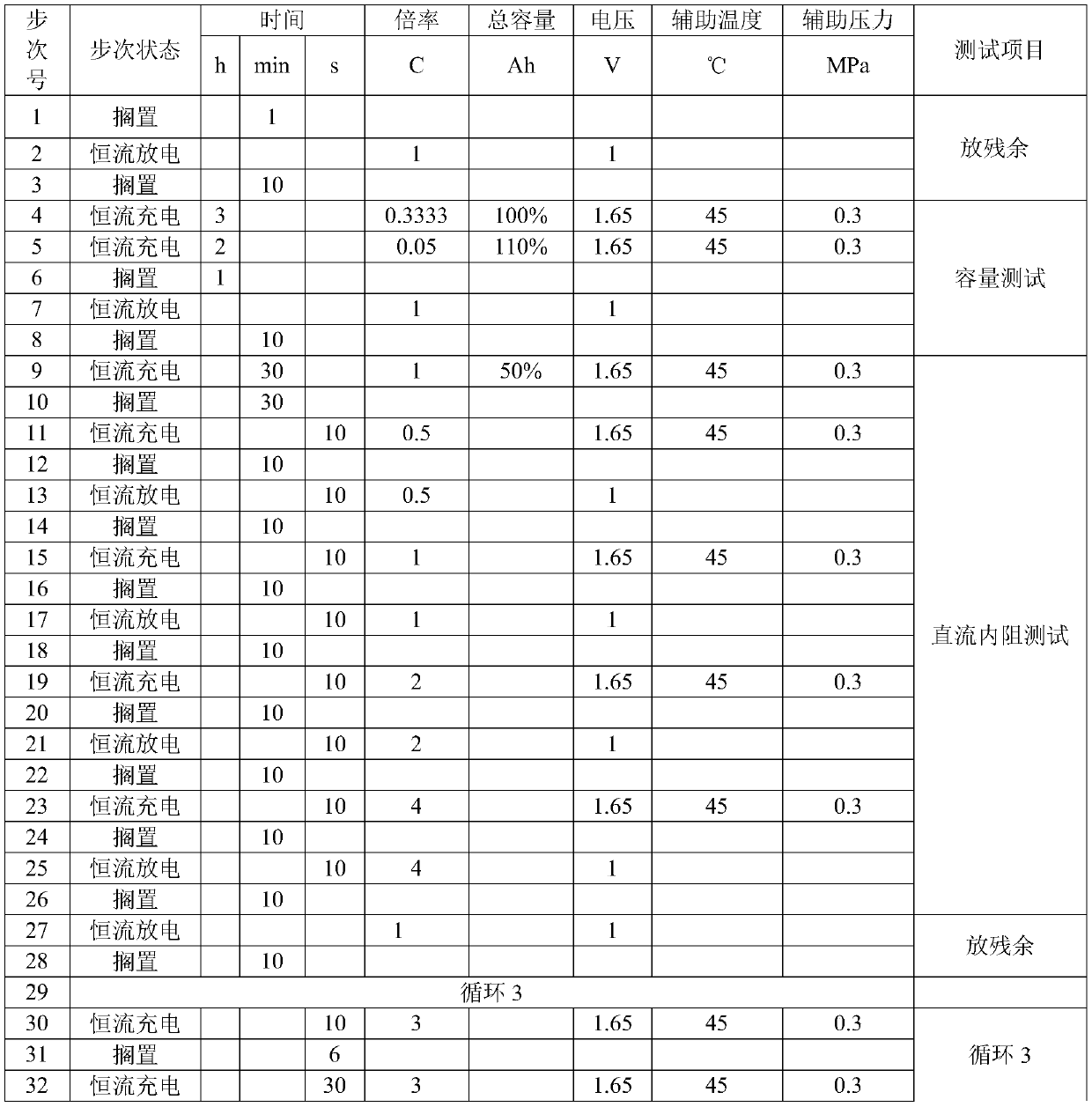

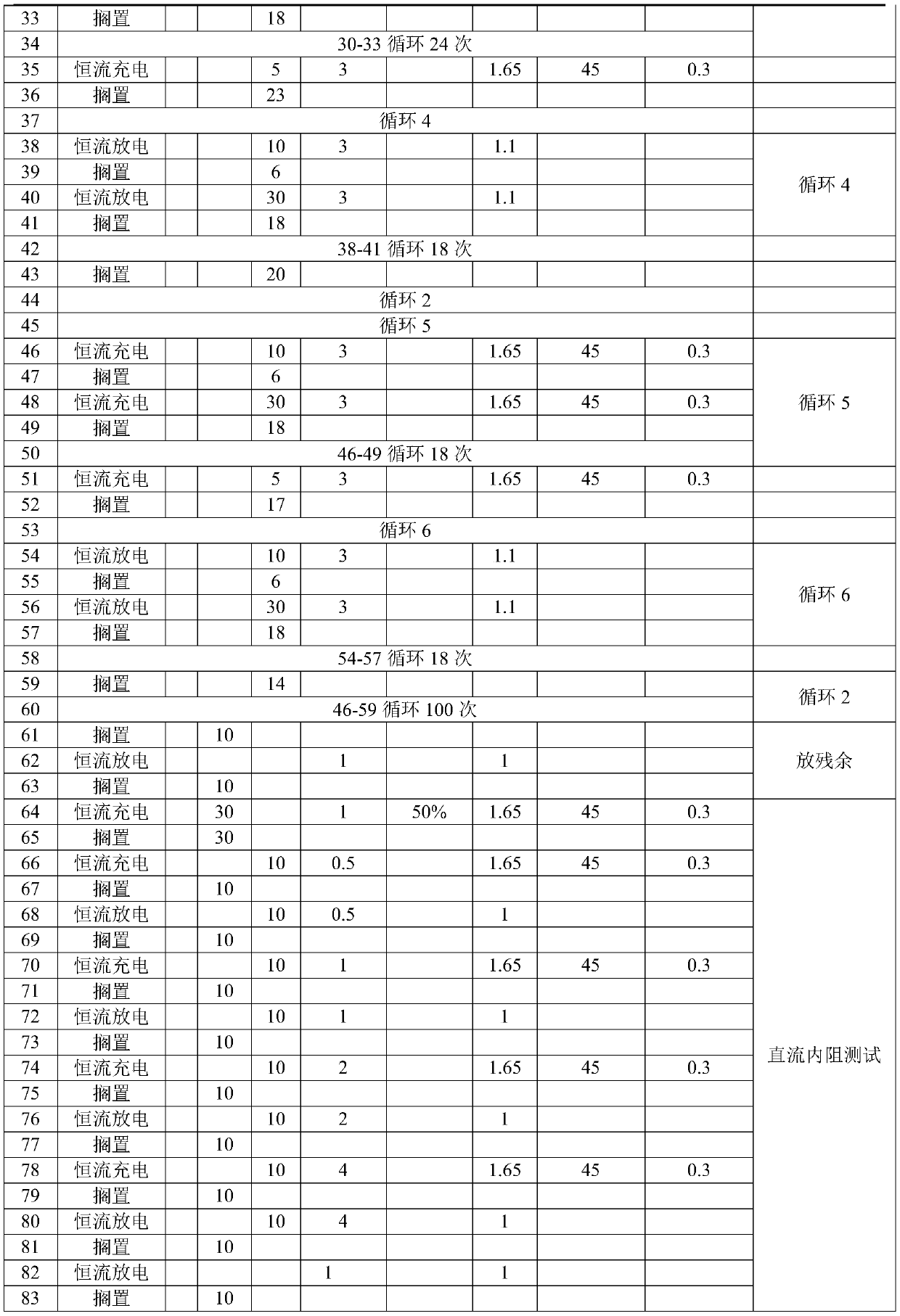

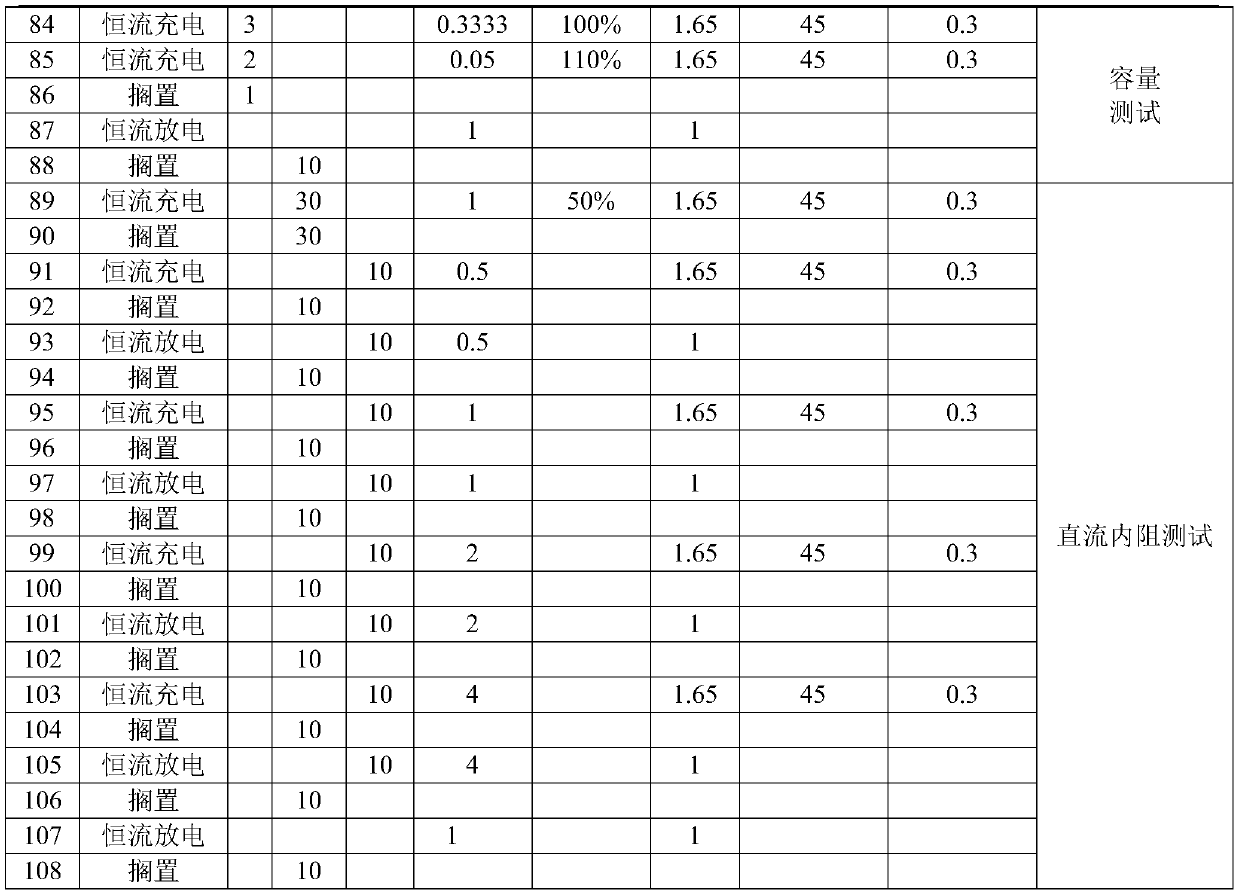

[0057] The invention provides a pulse cycle life test method suitable for nickel-metal hydride batteries used in electric vehicles, which mainly adopts the method of multiple battery discharge and intermittent pulse charge and discharge, and simulates the premise that the battery runs in the actual working conditions of the electric vehicle Under the condition of frequent starting, accelerating, braking, and stopping charging and discharging process, and then test the life of its pulse cycle. Test procedure of the present invention can be shown by following table:

[0058]

[0059]

[0060]

[0061] Remark:

[0062] (1) When the capacity test result in step 87 is lower than the specified value, stop the cycle test.

[0063] (2) The SOC of the test method of the present invention is cycled between 20% and 80%.

[0064] The above working steps are 29~60, and it takes 65.76h to complete 100 times.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com