Device and method for sintering iron ore and internally separating carbon dioxide

A carbon dioxide and iron ore technology, applied in the direction of reducing gas emissions, can solve problems such as waste, achieve long residence time, high flow rate, and reduce the effect of greenhouse effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

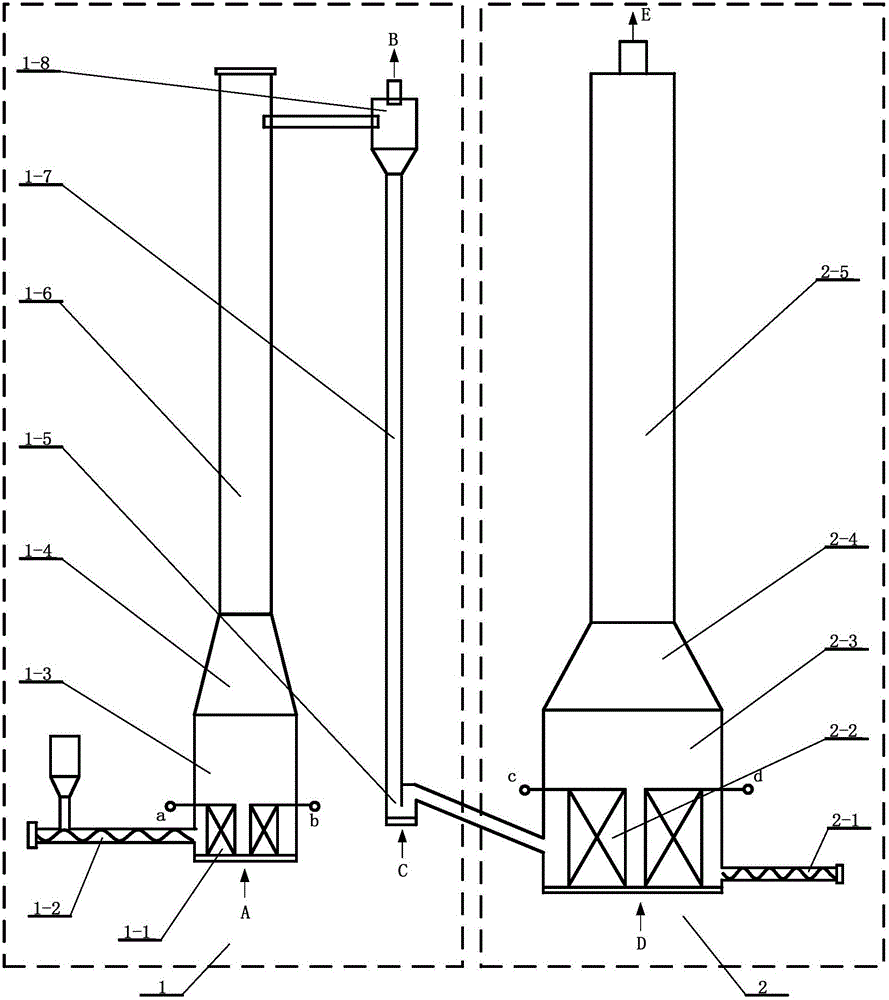

[0021] The present invention sinters iron ore and inherently separates CO 2 The device of the method is composed of a raw iron ore reduction reaction fluidized bed 1 and a reduced ore oxidation reaction fluidized bed 2. Raw iron ore reduction reaction fluidized bed 1 is composed of raw iron ore reduction reaction chamber 1-3, reduction reaction chamber transition section 1-4, reduction bed riser 1-6, carbon dioxide cyclone separator 1-8, and feeding pipe 1- 7. Consists of overflow tank 1-5, first heat exchanger 1-1 and feeder 1-2. The lower end of the reduction bed riser 1-6 is connected to the original iron ore reduction reaction chamber 1-3 through the reduction reaction chamber transition section 1-4, and the upper end of the reduction bed riser 1-6 is connected to the upper end of the carbon dioxide cyclone separator 1-8 The lower end of the carbon dioxide cyclone separator 1-8 is connected to the overflow tank 1-5 through the feeding pipe 1-7, the lower end side of the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com